Typical problems with structures in Heavy Lifting, Maritime, Offshore, Oil and Gas industries are cracks in the design, damaged structural parts, deformed plates or beams, severe corrosion and pitting, or rail misalignment. Such problems can be caused by structure load capacity, design, operating conditions, or weight changes. In addition, transportation, stability issues, the structure’s age or a remaining lifetime, and even the region where it is located may be reasons for the check. Proper assessments, calculations, and verifications are conducted by the SDC Verifier Engineering team using best-in-class software, assuring safety issues and other serious problems’ avoidance.

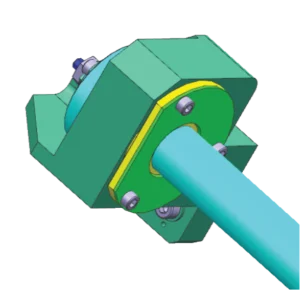

Our engineers help find the optimal design solution, which is a very challenging task. With the help of the devoted software they check simultaneously numerous structure elements (beams, joints, plates, bolts, rivets, pins, shafts, connections, welds) for compliance with standards, choosing from many options for model modification.

With the help of optimization, engineers define the best possible design, reduce the material quantity and construction cost, prevent stress concentrations, remove bottlenecks, and attain desirable performance attributes. Learn more about engineering FEA projects SDC Verifier Engineering Department complete for our clients in different industries.

Design checks and optimization help to ensure industry standards compliance and all verification steps smoothly overcoming. The complete process is done automatically and saves human time on intermediate iterations, significantly if something should be changed.

Stay updated with the latest in structural verification, engineering insights, and SDC Verifier updates.