BV NR615 Compliance for Marine Structures: A Comprehensive Guide

Buckling failures in marine structures, such as a containership’s hull collapse, can have devastating consequences.

Underscoring the need for robust integrity measures, the BV NR615 standard, established by Bureau Veritas Marine & Offshore in July 2023, provides a comprehensive framework for buckling assessment and ultimate strength analysis in ships and offshore installations.

By ensuring marine structures can withstand extreme loads, dynamic forces, and harsh environmental conditions, buckling assessment is crucial for safety and sustainability.

Let’s explore the pivotal role of BV NR615 in this process and its implications for safeguarding marine operations.

Key Concepts of Buckling Assessment

Understanding the key concepts of buckling assessment is essential for applying BV NR615 effectively. Let’s break down the fundamentals of buckling, ultimate strength, and the core theoretical principles used within the standard.

Buckling. Buckling is a type of failure mode that happens when a structural component, usually under compressive loads, collapses or deforms suddenly due to inadequate strength or stability. In marine environments, buckling can occur in various parts like columns, beams, plates, and shells, compromising overall structural integrity and safety.

Ultimate Strength. Ultimate strength refers to the maximum load or stress that a material or structural component can bear before it fails. In the context of buckling, knowing a structure’s ultimate strength helps engineers determine safety margins and ensure structures can withstand expected loads without collapsing.

Plate Buckling Behavior

- Unstiffened Plate (Plating between stiffeners): Thin plates commonly found in ship hulls and offshore structures are susceptible to buckling.

- Elastic and Inelastic Buckling:

- Elastic Buckling: The plate deforms under load but returns to its original shape when the load is removed.

- Inelastic Buckling: The plate undergoes permanent deformation due to stresses exceeding the material’s yield point.

Post-Buckling and Ultimate Strength: Understanding how plates behave after initial buckling is crucial. This helps determine their ultimate load-carrying capacity and how a potential failure might progress.

The Euler Buckling Theory forms the backbone of buckling analysis in BV NR615. It describes the relationship between a column’s length, material properties, and the critical load at which it will buckle. BV NR615 builds on this theory, adapting it for the unique geometries and boundary conditions of marine plates, beams, and other structural elements.

Buckling Checks Within BV NR615

BV NR615 outlines a structured approach to evaluate buckling in marine structures. The standard specifies a series of key sections that guide these checks:

-

Sec 2: Slenderness Requirements. Addresses the slenderness ratios (a ratio of dimensions and stiffness) of structural components like plates, stiffeners, and beams. Maintaining acceptable slenderness helps prevent buckling instability.

-

Sec 3: Prescriptive Buckling Requirements. Provides explicit formulas and criteria to assess buckling risk in various structural elements. These calculations often offer a conservative estimate of buckling capacity.

-

Sec 4: FE Analysis Requirements. Outlines how advanced Finite Element (FE) modeling can be used for more complex buckling assessments. This allows for highly detailed analysis of unique geometries or loading conditions.

-

Sec 5: Buckling Capacity. Focuses on determining the ultimate load a structure can withstand before buckling failure across both prescriptive analysis and FE analysis methods.

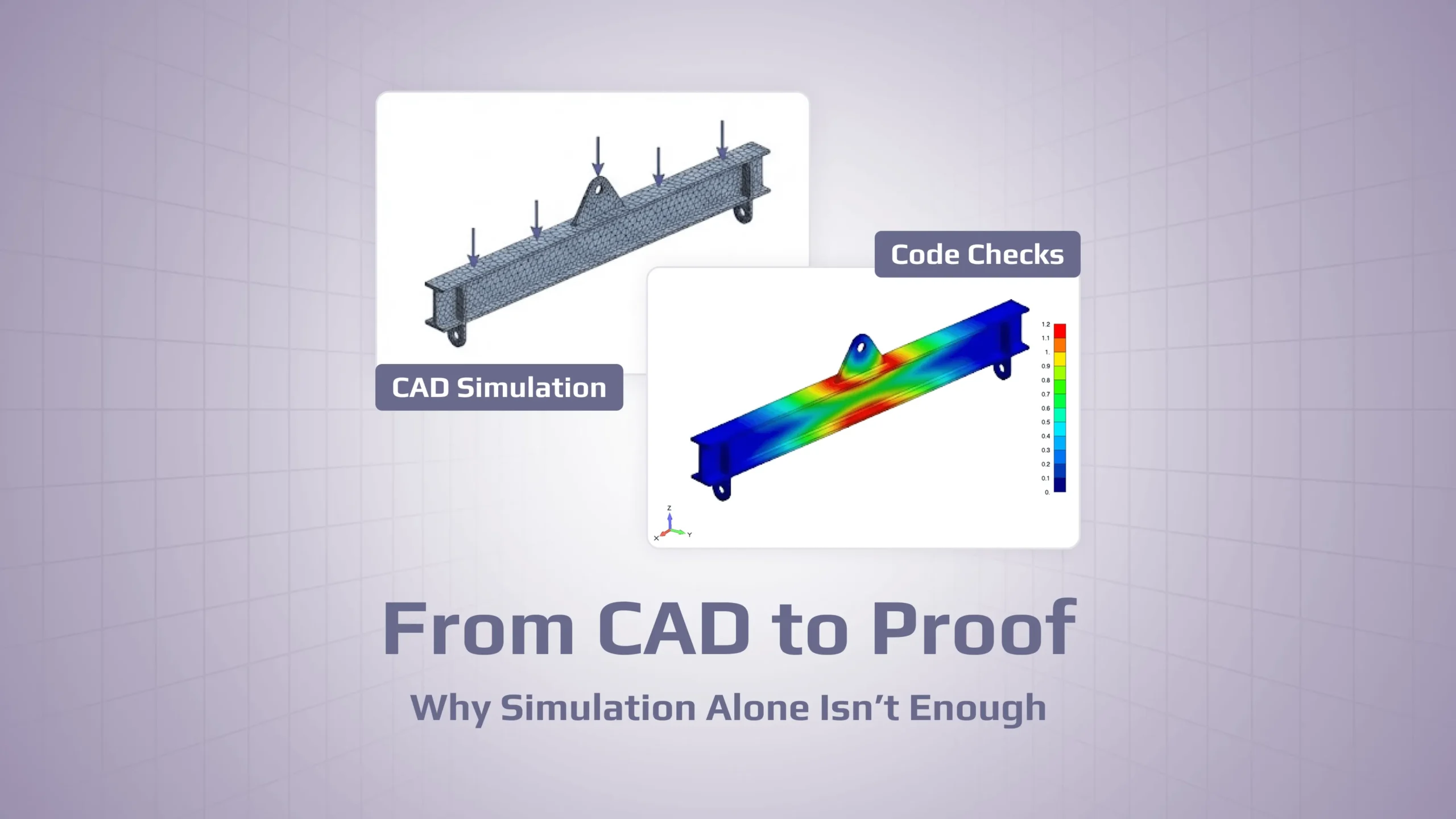

Elements Assessed in Direct Strength Analysis

Direct Strength Analysis (DSA) within BV NR615 focuses on buckling assessment in a range of common marine structural components. These include:

-

Panels: Both stiffened (with added beams/supports) and unstiffened panels are evaluated for buckling risk under various load types. Curved panels, often found in hull structures, require special consideration.

-

Web Plates: Web plates, especially those with openings for access or piping, can be susceptible to buckling. DSA helps ensure they maintain their structural integrity under expected in-service loads.

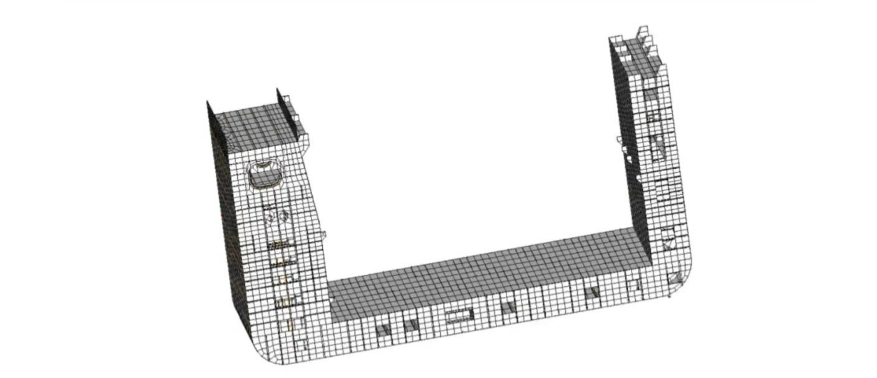

A plate model of the ship section

-

Bulkheads: Corrugated bulkheads provide strength and separation within vessels. Their strength and resistance to buckling are crucial for maintaining ship stability and compartmentalization.

-

Ship Structural Elements: DSA addresses buckling potential in specific ship components like the side shells of single-skin vessels. This ensures the overall hull construction is robust enough for its intended operational environment.

-

Supports: Struts, pillars, and cross ties all act as support elements. These must withstand compressive, shear, and lateral forces. DSA verifies they can bear the loads without buckling, which could lead to larger structural failures.

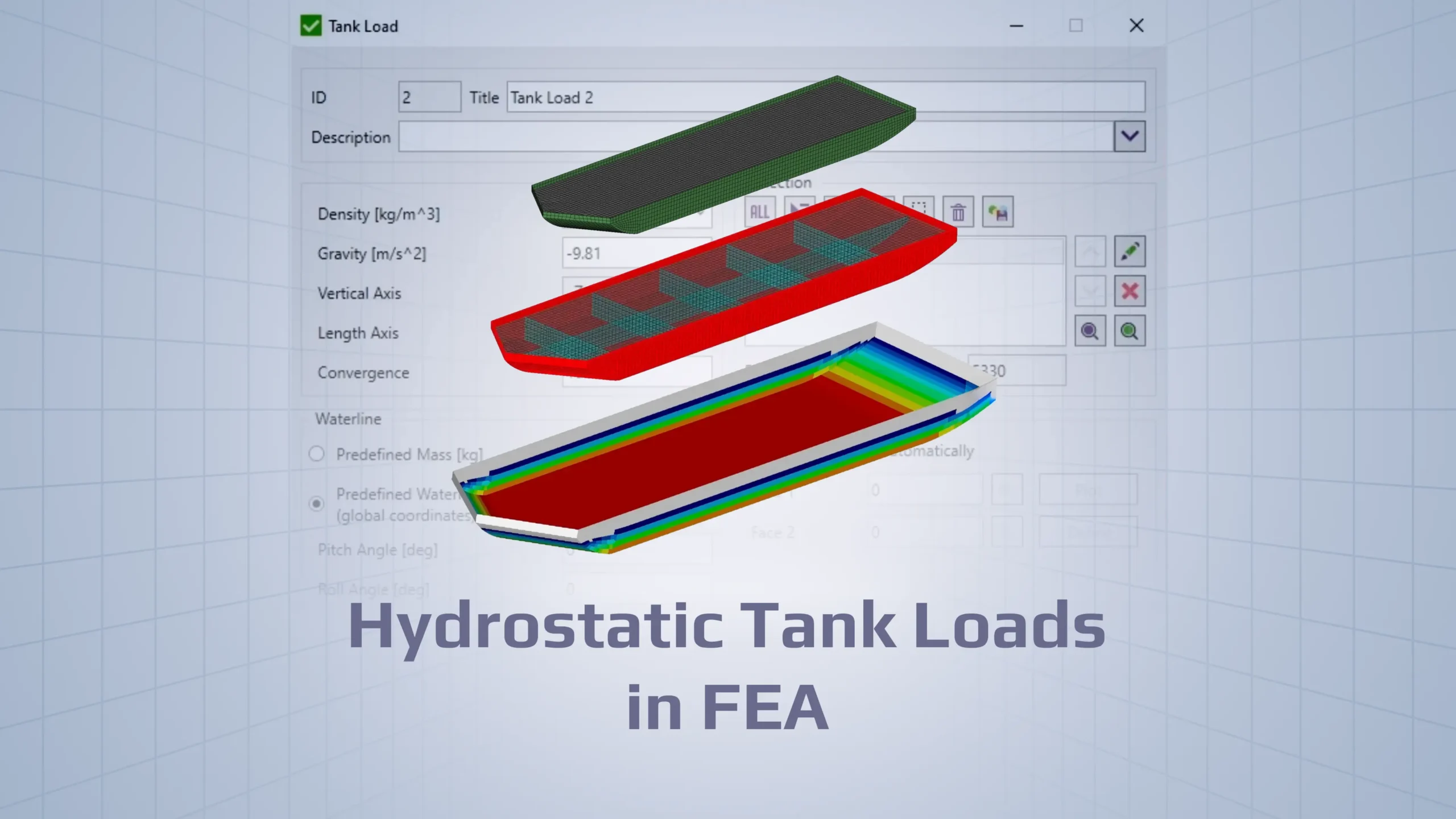

Streamlining Buckling Analysis: How SDC Verifier Implements BV NR615

SDC Verifier significantly simplifies compliance with BV NR615. By automating the standard’s theoretical calculations and providing robust reporting tools, the software saves engineers time and reduces the potential for errors.

Let’s explore how it achieves this.

Automating BV NR615 Calculations

In SDC Verifier software calculations according to BV NR615 are comprehensively performed in a streamlined and intuitive interface. The Panel Finder tool with all its benefits is used to recognize and set up the plates, as well as load combinations and all the other parameters.

Then in terms of the BV NR615 provisions:

1) In the standard creation window, the user defines the Assessment Method and Slenderness Coefficient for all the plates according to the standard requirements. Additionally, like other plate buckling checks, BV NR615 gives the option to perform the calculations with plate average stress as well as define the Thickness Factor which can be useful for quick checks on how changing the plate thickness would affect the results.

2) The calculations automatically check whether the Slenderness Requirement from Section 2 is fulfilled for all the plates.

3) Because the stresses are calculated using a weighted average approach as described in Appendix 1 of the Standard the edge stress ratios are taken as equal to 1.

4) All the factors and coefficients in Sec 5, [2.2] are calculated or picked from the according tables, including the Buckling Factor K and Reduction Factor C from Table 4 from the respective cases.

5) In the final step all the results obtained to this point are used to calculate the Plate Limit State using the four interaction formulae given in Sec 5, [2.2.1]. Out of these is then picked the maximum utilization factor for the given plate.

Advanced Post-Processing with SDC Verifier

Buckling analysis results in a vast dataset, and interpreting this data is crucial for optimizing design decisions. SDC Verifier offers specialized tools to streamline post-processing, saving engineers significant time and effort.

With the help of the Peak Finder tool in SDC Verifier, all peak stresses and other types of outcomes (i.e., standard check results, strain, weld stresses, global plate stresses, line element forces, etc.) can be found in seconds and automatically generated in a unique plot and a summary table.

The tool’s different features allow users to set up only the interested criteria for findings and avoid unnecessary outcomes. Often, it saves hours, days, and even weeks compared to the manual post-processing routine.

When calculating structures with dozens of different stresses and load zones, engineers often need to choose specific ranges of stresses or utilization factors for more detailed analysis.

SDC Verifier Governing loads tool allows choosing the critical load in all selected zones. So, the user doesn’t need to use thousands of small peaks and can focus only on the ones with high-stress levels. Each zone will be automatically stored in the selection of the Governing loads tool. Out of a large group of load combinations, the SDC Verifier Governing loads tool extracts the critical loads and reduces calculation time.

Freebody is an SDC Verifier post-processing tool that calculates a balanced set of forces/moments on a selected part of a model using the interface load method. It is possible to retrieve internal/external loads to be used for substructure modeling or to find contact/connector forces by manipulating a user-defined selection of nodes/elements.

Check the theory and practical examples of post-processing tools usage in our video.

Check a sample T-joint plate model, Ship section plate model, or Crane boom plate model that can be verified according to BV NR615 in SDC Verifier.

Conclusion

BV NR615 stands as a cornerstone of marine safety, providing essential guidelines for the assessment and verification of structural components in marine vessels and offshore installations. By ensuring compliance with this standard, engineering teams uphold the highest standards of safety and reliability, mitigating the risk of structural failures and safeguarding lives, assets, and the environment. Adherence to BV NR615, aided by tools like SDC Verifier, offers numerous benefits that optimize ship design and minimize risk:

Enhanced Safety: Compliance with BV NR615 ensures that marine structures meet stringent safety standards, reducing the likelihood of structural failures and associated risks.

Improved Structural Integrity: By systematically assessing structural elements for susceptibility to buckling, adherence to the standard enhances the overall integrity and resilience of marine vessels and offshore installations.

Efficient Design Process: SDC Verifier streamlines the structural analysis process, accelerating decision-making and reducing time and resource investment in ship design and verification.

Cost Savings: By minimizing the risk of structural failures and design inefficiencies, adherence to BV NR615 and utilization of tools like SDC Verifier contribute to cost savings throughout the project lifecycle.

Regulatory Compliance: Compliance with BV NR615 ensures alignment with regulatory requirements and industry best practices, enhancing the organization’s reputation and competitiveness in the maritime sector.

As engineers strive to uphold the highest standards of marine safety and structural integrity, BV NR615 and leveraging tools like SDC Verifier are crucial to optimize ship design and minimize risk, prioritizing safety, innovation, and excellence in the maritime industry.