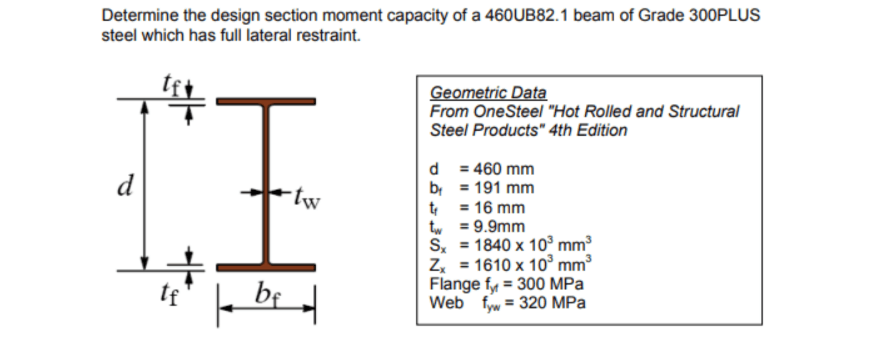

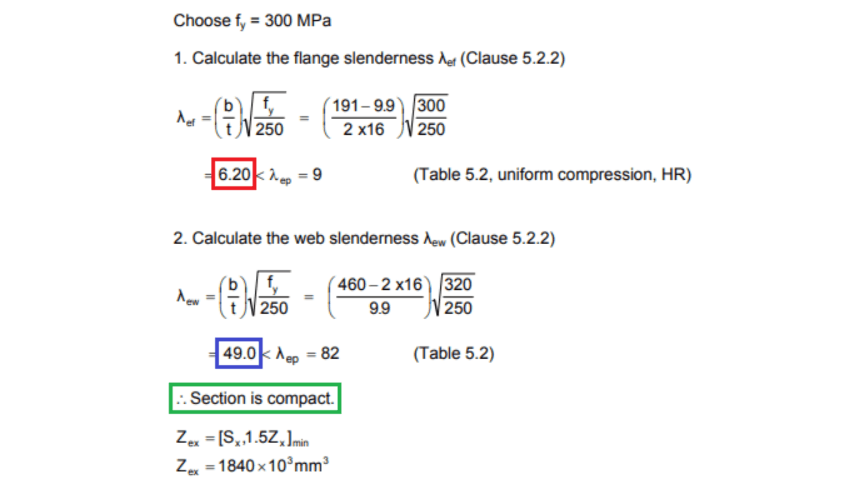

AS 4100. Example 1: Determine the Design Section Moment Capacity of a Universal Beam with Full Lateral Restraint

This benchmark was prepared based on

Australian Steel Institute (ASI) Steel Structures – Sample Worked Problems to AS 4100

using

SDC for Femap and Simcenter Femap Version 2022.2

This benchmark serves as a rigorous validation of SDC Verifier’s capabilities in calculating Design Section Moment Capacity for a Universal Beam under full lateral restraint, as per AS 4100. We dissect input parameters, address modeling challenges inherent to FEA, and critically analyze results to showcase the software’s precise adherence to code requirements.

Discrepancies arising from FEA limitations are explicitly identified and explained, underscoring SDC Verifier’s robustness and reliability in structural steel beam design validation.

Ensure your AS 4100 steel beam designs adhere to code requirements. In this benchmark example, we’ll determine the Design Section Moment Capacity with full lateral restraint using SDC Verifier 2024 R1.

You’ll get a detailed breakdown of input parameters, modeling considerations (including FEA software limitations), and results analysis.

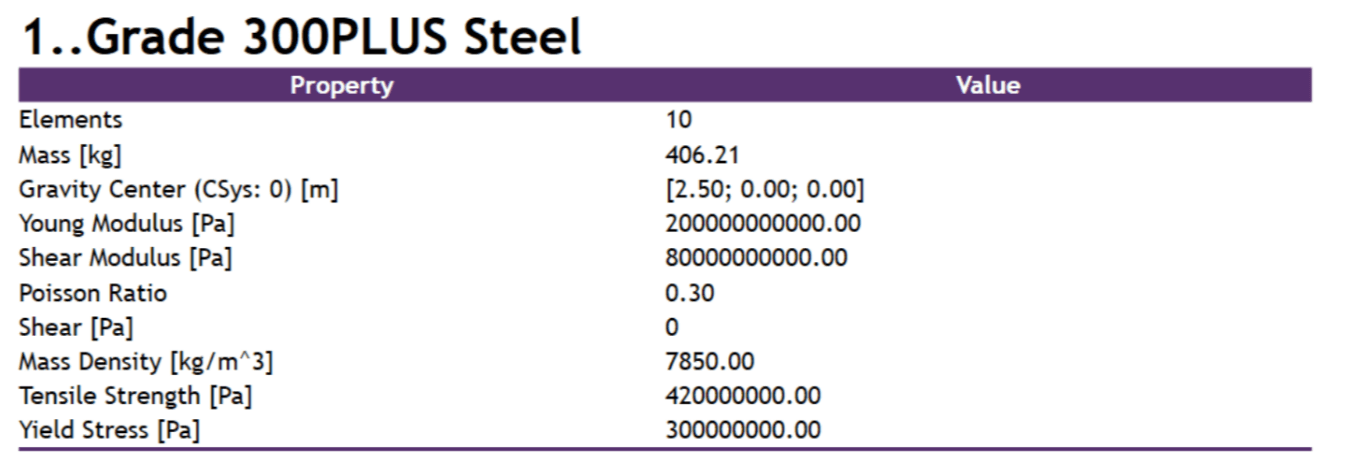

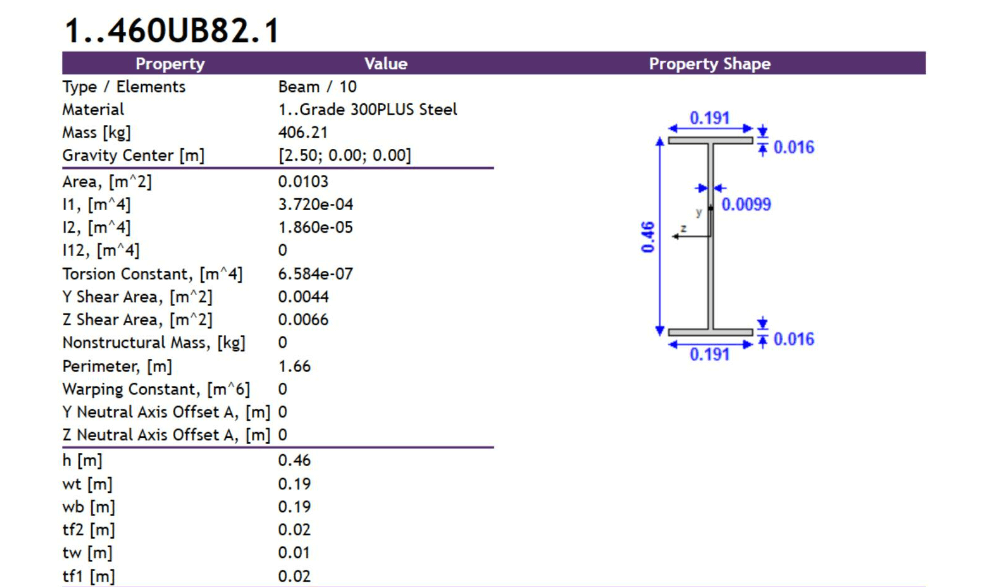

Based on the input parameters presented above a beam model was created with the following material and property definitions:

Note: Because of the limitations of the FEA software the cross-section is defined without fillets, so slight differences in geometrical properties are to be expected.

Where possible these values have been modified manually (as for the moments of inertia I1 and I2 in the table above), but some are calculated internally without the possibility to modify them (e.g. plastic section modulus).

Additionally, the yield stress is defined with one value for the beam property, so it’s the same for both the web and the flange, while in the problem definition there is one value for the flange – 320 MPa, and a different value for the web – 320 MPa, so the lesser value was chosen.

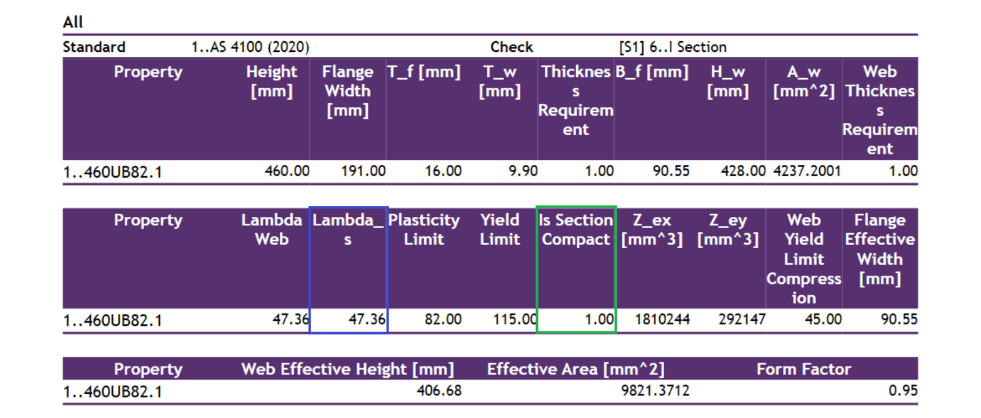

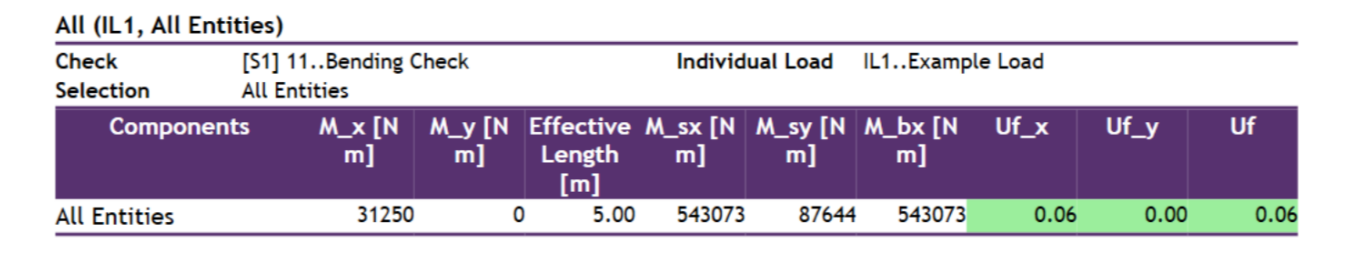

The above parameters are checked within a Property Check, in this case, one defined for I-Beam cross-sections.

SDC Verifier follows the logic presented in the standard, where out of the two checked slenderness values (for the flange and the web) the governing one is picked as the section slenderness (Lambda_s in the above table).

As we can see the value of the slenderness is slightly lower for the already mentioned reason of using the lower value of the yield stress for the whole cross-section. Similarly, the value of the effective section modulus (Z_e) is also lower (1810 ∗ 103 mm3 compared to 1840∗103 mm3, so by about 1.6%), because of the mentioned limitations of the FEA software.

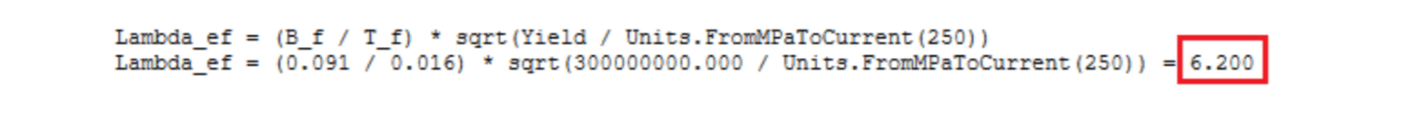

We can also see the flag Is Section Compact which confirms that the section is compact (1.00=yes). In the calculation details, we can additionally check the flange slenderness value (Lambda_ef):

which matches the value in the example.

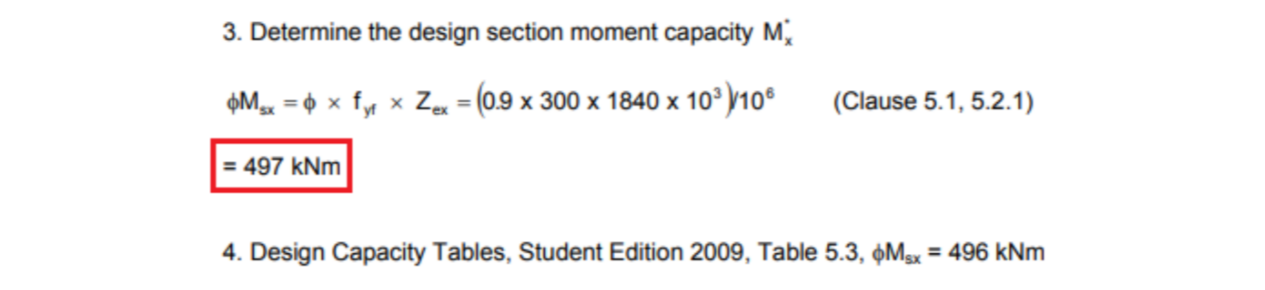

When calculating the nominal section moment capacity (M_sx) SDC Verifier follows the logic of the standard as well, so the multiplication by the capacity factor ? happens later when comparing it to the design bending moment.

That’s why the value obtained in the table has to be additionally reduced by ф for the purposes of the calculations in this example:

ф∗Msx = 0.9∗543073 Nm = 489 kNm

As we can see the obtained value is slightly lower than in the example, but that’s due to the already mentioned lack of possibility to define fillets for the cross-section in the FEA software. If we were to increase it by the 1.6% that was lost due to this inaccuracy in the plastic section modulus, we would obtain values that completely match (489 kNm∗101.6 %= 497 kNm).

Conclusion

This benchmark unequivocally demonstrates SDC Verifier’s accuracy in computing Design Section Moment Capacity in full compliance with AS 4100. While minor geometric variations due to FEA are noted, the core calculation methodology remains strictly aligned with the standard.

This post uses screenshots from the Steel Structures Sample Worked Problems to AS 4100 document