Eurocode 3. Example 6.6: Cross-section resistance under combined bending and compression

In this article we compare the resistance under combined bending and compression according to SDC Verifier and Designer’s Guide to Eurocode3: Design of steel buildings EN 1993-1-1.

All results are generated with SDC Verifier 4.5 and calculated with FEMAP v11.3.1

Task:

A member is to be designed to carry a combined major axis bending moment and an axial force. In this example, a cross-sectional check is performed to determine the maximum bending moment that can be carried by a UKB 457 x 191 x 98 in grade S275 steel, in the presence of an axial force of 1400 kN.

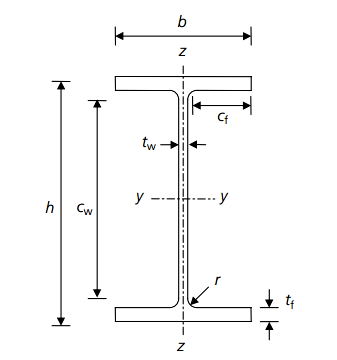

Figure 6.15. Section properties for a 457 × 191 × 98 UKB

|

|

Solution:

Model

Materials

| Title | Young Modulus [Pa] | Shear Modulus [Pa] | Poisson Ratio | Shear [Pa] | Mass Density [kg/m^3] | Tensile Strength [Pa] | Yield Stress [Pa] |

|---|---|---|---|---|---|---|---|

| 1..S275 | 2.10e+11 | 0 | 0.3000 | 0 | 7850.0000 | 355.00e+6 | 265.00e+6 |

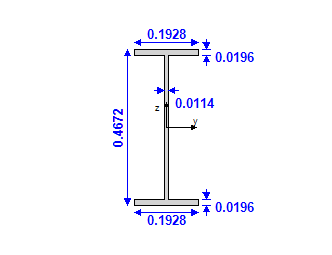

Property “1..UKB 457x191x98”

| Property | Value | Property Shape |

|---|---|---|

| Type / Elements | Beam / 6 |  |

| Material | 1..S275 | |

| Mass [kg] | 137.4 | |

| Gravity Center [m] | [0.70; 0.00; 0.00] | |

| Area, [m^2] | 0.0125 | |

| I1, [m^4] | 2.346e-05 | |

| I2, [m^4] | 4.533e-04 | |

| I12, [m^4] | 0 | |

| Torsion Constant, [m^4] | 1.160e-06 | |

| Y Shear Area, [m^2] | 0.0081 | |

| Z Shear Area, [m^2] | 0.0051 | |

| Nonstructural Mass, [kg] | 0 | |

| Perimeter, [m] | 1.68 | |

| Warping Constant, [m^6] | 0 | |

| Y Neutral Axis Offset A, [m] | 0 | |

| Z Neutral Axis Offset A, [m] | 0 | |

| h [m] | 0.467 | |

| wt [m] | 0.193 | |

| wb [m] | 0.193 | |

| tf2 [m] | 0.020 | |

| tw [m] | 0.011 | |

| tf1 [m] | 0.020 |

Boundary Conditions

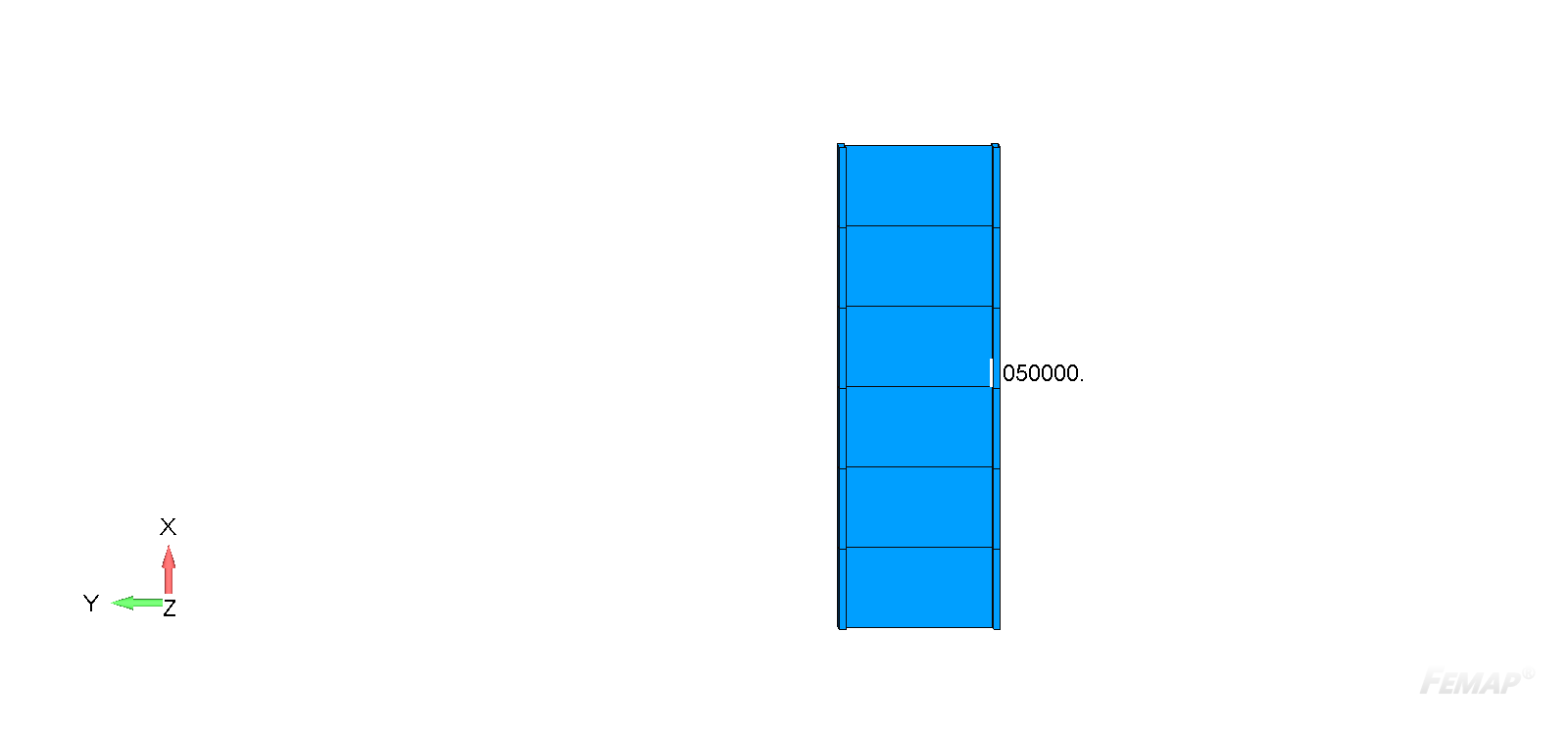

Load “1..Shear -Y = 1050kN”

| Definition | Load Type | Applied On | Values |

|---|---|---|---|

| Force on Node | Force | Nodes: 4 | (0; -1050000; 0) |

|

|||

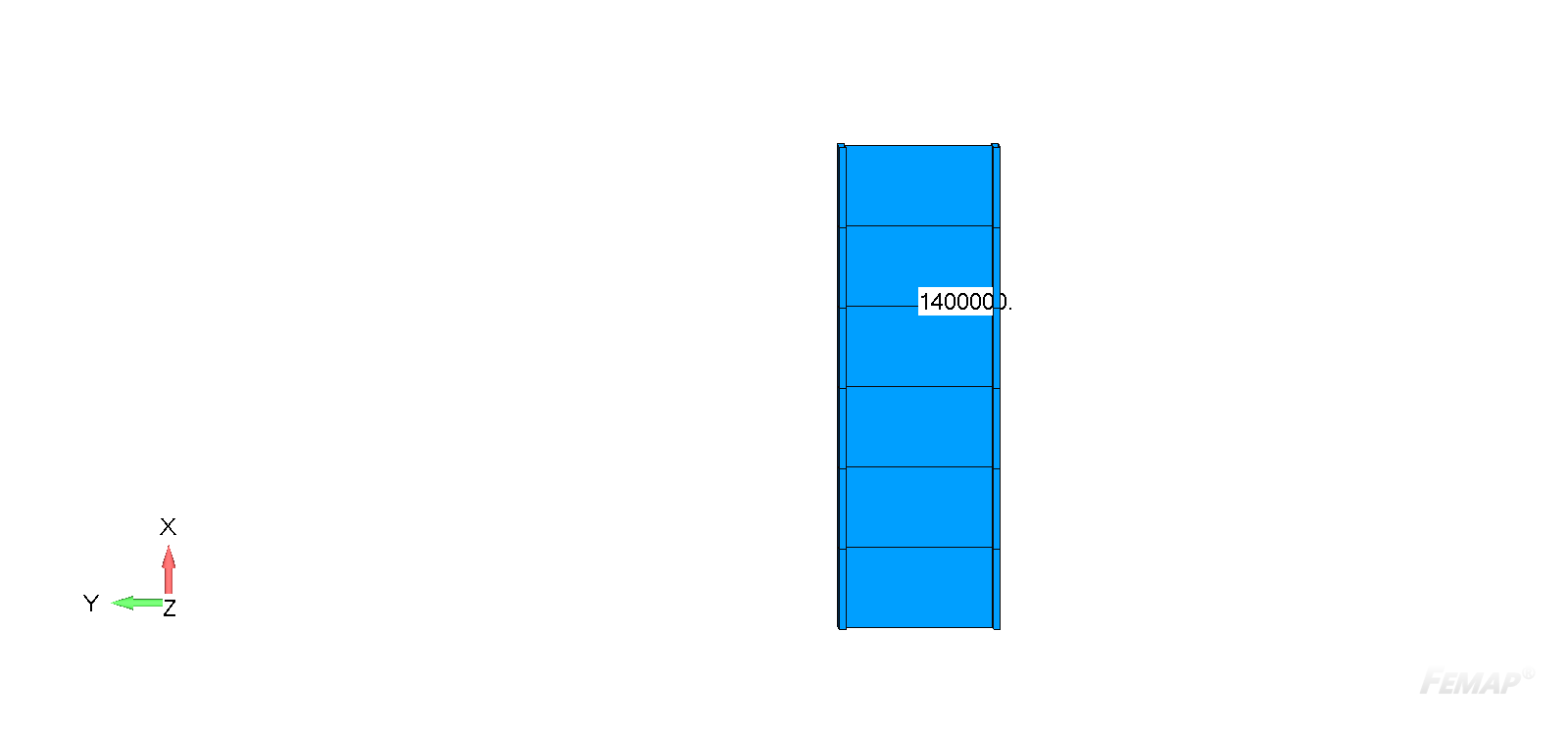

Load “2..Axial 1400N”

| Definition | Load Type | Applied On | Values |

|---|---|---|---|

| Force on Node | Force | Nodes: 4 | (1400000; 0; 0) |

|

|||

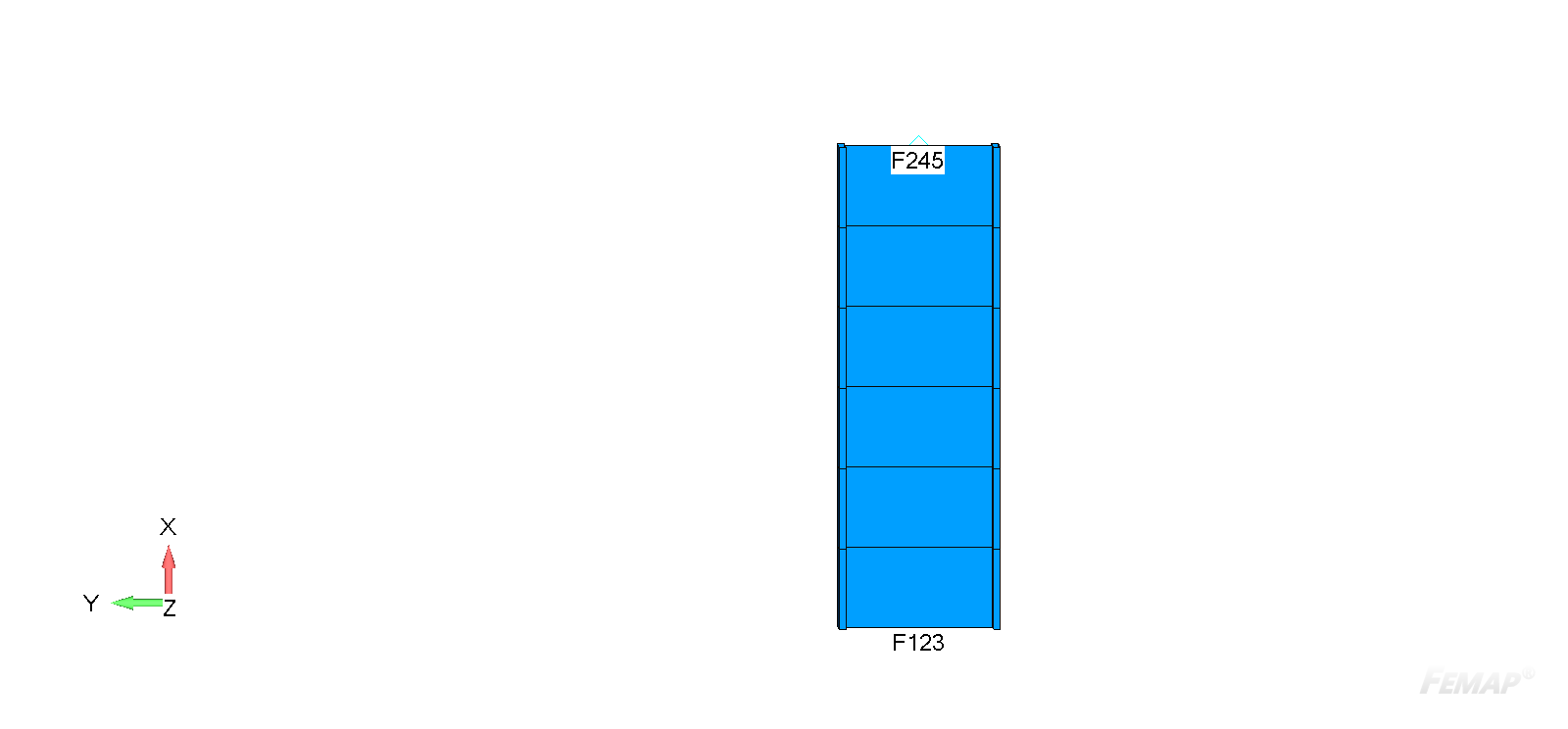

Constaint “1..fixed”

| Definition | Count | DOF |

|---|---|---|

| Constraint on Node | Nodes: 1 | Tx Ty Tz |

| Constraint on Node | Nodes: 7 | Ty Rx Ry |

|

Classificaton

| Standard | 2..Eurocode 3 Member Checks | Check | 7..Classificaton |

| Individual Load | 1..Axial 1400kN | Direction | All |

| Selection | All Entities |

| Load | Alpha Web | Phi | Lambda Web | Limit1 Web | Limit2 Web | Limit3 Web | Web Class | Class |

|---|---|---|---|---|---|---|---|---|

| Individual Load ‘1..Axial 1400kN’ | 1.0000 | -0.1547 | 35.7544 | 31.0760 | 35.7845 | 63.9012 | 2.0000 | 2.0000 |

Cross-section classification under pure compression (clause 5.5.2)

\[\varepsilon =\sqrt{235/f_{y}} \ =\sqrt{235/265} \ =0.94\]

Outstand flanges (Table 5.2, sheet 2):

\[c_{f} \ = (b – t_{w} – 2r)/2 \ = 80.5 mm\]

\[c_{f}/t_{f} \ = 80.5/19.6 = 4.11\]

Limit for Class 1 flange = 9ε = 8.48

8.48 > 4.11 ∴ flange is Class 1

Web — internal part in compression (Table 5.2, sheet 1):

\[c_{w} \ = h – 2t_{f} – 2r \ = 407.6 mm\]

\[c_{w}/t_{w} \ = 407.6/11.4 = 35.75\]

Limit for Class 2 web = 38ε = 35.78

35.78 > 35.75 ∴ web is Class 2

Under pure compression, the overall cross-section classification is therefore Class 2 . Consequently, unlike Example 5.1, nothing is to be gained by using the more complex approach of considering the actual stress distribution.

11..Bending and Axial

| Standard | 2..Eurocode 3 Member Checks | Check | 11..Bending and Axial |

| Individual Load | 1..Axial 1400kN | Direction | All |

| Selection | 1..Eurocode3 Shapes |

| Extreme | n | Reduced Resistance Y | Reduced Resistance Z | Uf Reduced Y | Uf Reduced Z | Alpha | Beta | Uf Combined |

|---|---|---|---|---|---|---|---|---|

| Minimum | 0.42 | 100016.5 | 422113.0 | 0.00 | 0.00 | 2.00 | 2.11 | 0.00 |

| Maximum | 0.42 | 100016.5 | 422113.0 | 0.00 | 0.00 | 2.00 | 2.11 | 0.00 |

| Absolute | 0.42 | 100016.5 | 422113.0 | 0.00 | 0.00 | 2.00 | 2.11 | 0.00 |

Conclusion

In order to satisfy the cross-sectional checks of clause 6.2.9, the maximum bending moment that can be carried by a 457 x 191 x 98 UKB in grade S275 steel, in the presence of an axial force of 1400 kN is 425.3 kN m .

For class 2 elements in calculation take into account fillets. In shapes fillets are skipped and it gives the difference of 0.007% in results.

Check other comparation of Eurocode3 design examples standard and SDC Verifier.