Example E1.B and E1.D W-shape column design with intermediate bracing

The results are generated with SDC Verifier 3.6 and calculated with FEMAP v11.0.0

Task:

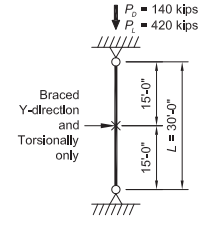

Redesign the column from Example E. 1A assuming the column is laterally braced about y-y axis and torsionally braced at the midpoint.

Solution:

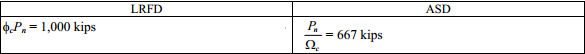

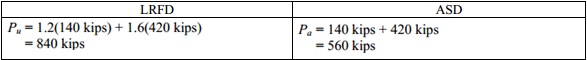

From Chapter 2 of ASCE/SEI 7, the required compressive strength is:

Column Selection

From AISC Specification Commentary Table C-A-7.1, for a pinned-pinned condition, K = 1.0.

Because the unbraced length differ in the two axes, select the member using the y-y axis then verify the strength in the x-x axis.

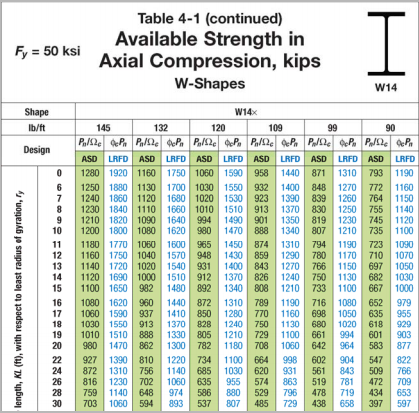

Enter AISC Manual Table 4-1 with a y-y axis effective length, KLy, of 15 ft and proceed across the table until reaching a shape with an available strength that equals or exceeds the required strength. Try a W14×90. A 15 ft long W14×90 provides an available strength in the y-y direction of:

The rx/ry ratio for this column, shown at the bottom of AISC Manual Table 4-1, is 1.66. the equivalent y-y axis effective length for strong axis buckling is computed as:

From AISC Manual Table 4-1, the available strength of a W14×90 with an effective length of 18 ft is:

The available compressive strength is governed by the x-x axis flexural buckling limit state.

The available strength of the columns described in Examples E.1A and E.1C are easily selected directly from the AISC Manual Tables. The availiable strength can also be verified by hand calculations, as shown in the following Examples E.1C and 1D.

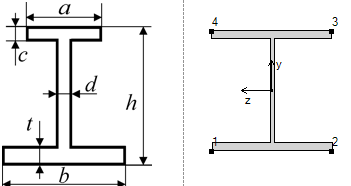

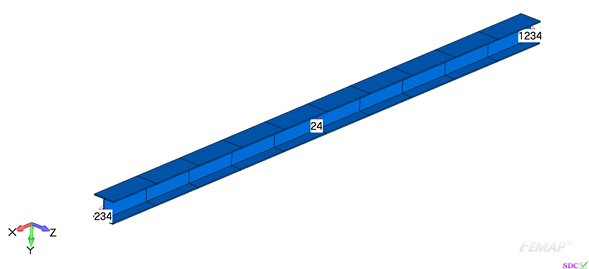

Material used is Steel ASTM A992 with mass 4674600.00, Gravity Center = 180.00; 0.00; 0.00 and property W14x132

Area, moment Izz, moment Iyy and other shape parameters are corrected because in FEMAP it calculated without taken into account fillets and chamfers.

| Geometry Property | Value |

|---|---|

| Height | 14.00 |

| Width | 14.50 |

| h | 14.00 |

| a | 14.50 |

| b | 14.50 |

| c | 0.71 |

| d | 0.44 |

| t | 0.71 |

Example from AISC Design Examples

The properties are as follows:

- W14×90

FEM Loads and Constraint

1..Dead load 140 kips

| Definition Title | Load Type | Applied on | Value(s) |

|---|---|---|---|

| 1.140 kips | Force | Node: 11 | (-140000;0;0) |

2..Live load 420 kips

| Definition Title | Load Type | Applied on | Value(s) |

|---|---|---|---|

| 1..420 kips | Force | Node: 11 | (-420000;0;0) |

Constraint

1.. Pinned

| Definition | Count | Type (DOF) |

|---|---|---|

| 1..Top | 1 node(s) | Ty Tz Rx |

| 2..Bottom | 1 node(s) | Tx Ty Tz Rx |

| 3..Ty;Rx | 1 node(s) | Ty Rx |

Check 1..ANSI / AISC LRFD 360-10

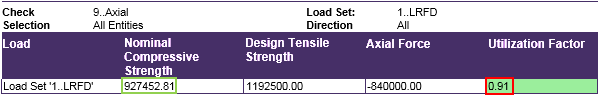

Axial check

All (LS1, All Entities)

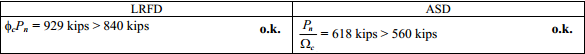

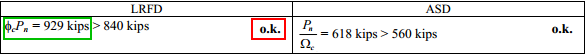

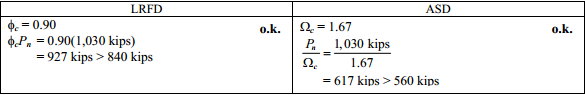

From AISC Manual Table 4-1, the available strength of a W14×90 with aneffective length of 18 ft is:

The available compressive strength is governed by the x-x axis flexural buckling limit state.

Example E.1D W-shape available strength calculation

The results are generated with SDC Verifier 3.6 and calculated with FEMAP v11.0.0

Task:

Calculate the available strength of a W14×90 with a strong axis unbraced length of 30 ft and weak axis and torsional unbraced lengths of 15 ft. The material properties and loads are as given in Example E.1A.

Solution

From AISC Manual Table 2-4, the material properties are as follows:

ASTM A992

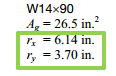

From AISC Manual Table 1-1, the geometric properties are as follows:

- W14×90

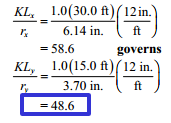

- Ag = 26.5 in.2

- rx = 6.14 in.

- ry = 3.70 in.

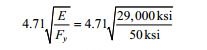

Slenderness Check

From AISC Specification Commentary Table C-A-7.1, for a pinned-pinned condition, K = 1.0.

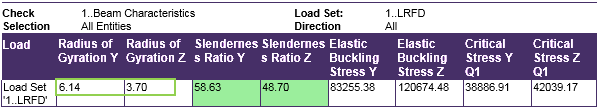

Critical Stresses

The available critical stresses may be interpolated from AISC Manual Table 4-22 or calculated directly as follows:

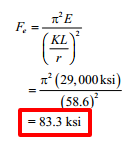

Calculate the elastic critical buckling stress, Fe–

Calculate the flexural buckling stress, Fcr-

Nominal Compressive Strength

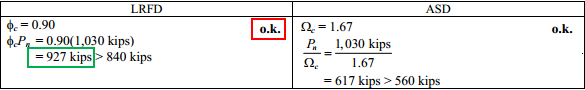

From AISC Specification Section E1, the available compressive strength is:

Example from AISC Design Examples

The properties are as follows:

- W14×90

- Ag = 26.5 in.2 = 0.18. ft2

Beam Characteristics

All (LS1, 1 Elemet(s))

From AISC Manual Table 4-1, the geometric properties are as follows:

Slenderness Check

From AISC Specification Commentary Table C-A-7.1, for a pinned-pinned condition, K = 1.0.

Calculate the elastic critical buckling stress, Fe–

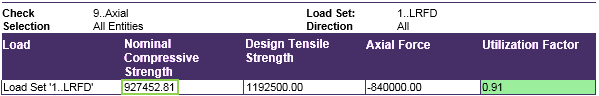

Axial check

All (LS1, All Entities)

From AISC Specification Section E1, the available compressive strength is:

Comparing results of calculation in SDC Verifier and in Example E.1B and Example E.1D we can see that values completely match.

The available compressive strength is 927 kips.

Download SDC Verifier project file, model and report of Example E1B-1D