Plate Buckling Assessment According to LR CSR (2024) – Hand Calculations vs. SDC Verifier Validation

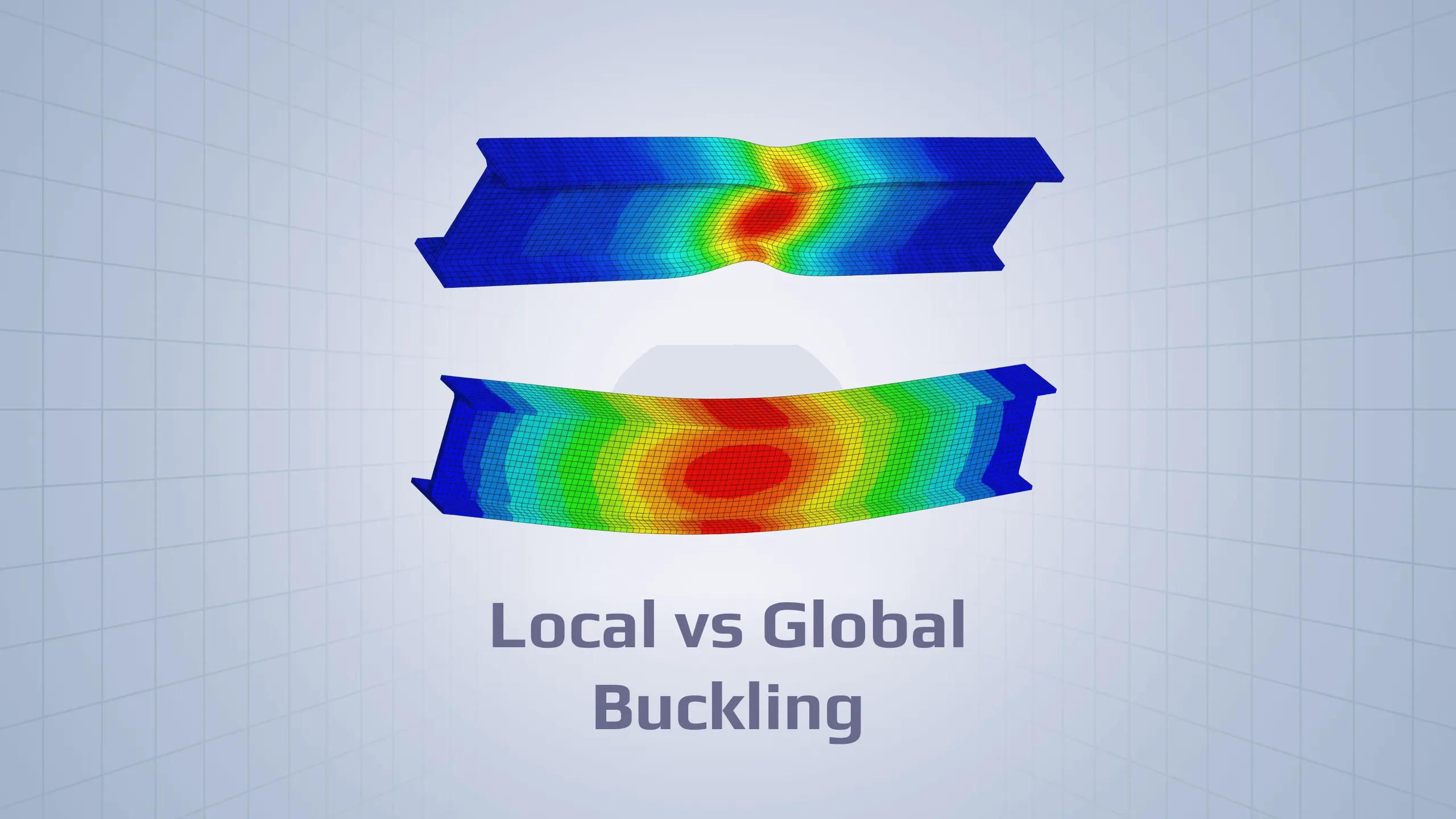

This benchmark evaluates the accuracy and reliability of plate buckling analysis performed using SDC Verifier by comparing it with detailed hand calculations based on the LR Common Structural Rules (CSR) for Bulk Carriers and Oil Tankers (2024 edition), specifically Part 1, Chapter 8 – Buckling.

A test plate with dimensions 10.2 × 5.4 × 1.1 meters was modeled and loaded with a combination of axial, transverse, and shear forces. One of the top plates—3.4 × 1.35 meters with 12 mm thickness—was selected for a focused verification check. The material used was mild steel, and all boundary conditions, loading scenarios, and code-based coefficients were applied consistently across both calculation methods.

The objective was to:

-

Verify slenderness requirements,

-

Calculate elastic buckling stress and critical stress factors,

-

Solve all four LR CSR limit state equations analytically,

-

Derive ultimate buckling stresses and utilization factor,

-

Validate results via a full FEM simulation and SDC Verifier check.

A test plate model with 10.2 × 5.4 × 1.1 m dimensions was designed for the purpose of this benchmark:

The model was constrained at four bottom corners where side plates are connected. Forces were applied on the edges of the top plate with the following values:

Selected Plate and Material Properties

One of the top plates was chosen for all the calculations included in the check.

Plate dimensions:

-

Length:

-

Width:

-

Thickness:

Mild steel material properties:

-

Young’s Modulus:

-

Poisson’s Ratio:

-

Mass Density:

-

Tensile Strength:

-

Yield Stress:

Due to the complexity of the model, all required stress values were obtained with the help of FEM.

Obtained values:

In order to check the results, analytical calculations were first carried out.

Slenderness requirement check (Pt. 1, Ch. 8, Sec. 2 / [2.2.1]):

✅ 12 mm > 10.8 mm

Final Equations for Limit States

(According to code Pt. 1, Ch. 8, Sec. 5 / [2.2.1]):

I.

II. (when

III. (when

IV.

Aspect Ratio of the Plate Panel

(Pt. 1, Ch. 8, Sec. 5 / Symbols)

The aspect ratio of the plate panel is defined as the ratio of its length to width :

Elastic Buckling Reference Stress

(Pt. 1, Ch. 8, Sec. 5 / Symbols)

The elastic buckling reference stress was calculated using the formula:

Substituting the known values:

Edge Stress Ratio and Correction Factors

-

Edge stress ratio

was set as 1 in both directions:

(Pt. 1, Ch. 8, Sec. 5 / Symbols; stresses calculated using weighted average approach, Pt. 1, Ch. 8, App. 1 / [2.2.1])

-

Correction factor

was set as 1:

(Pt. 1, Ch. 8, Sec. 5 / [2.2.4]; Table 2)

-

Correction factor

was also set as 1:

(Pt. 1, Ch. 8, Sec. 5 / [2.2.5])

Ultimate buckling stresses were calculated in 3 cases:

(Pt. 1, Ch. 8, Sec. 5 / Table 3)

Case 1:

Plate Buckling Setup

The plate is compressed along the x-direction with an edge stress ratio .

Intermediate Parameters:

-

Effective width factor

-

Slenderness parameter

-

Buckling factor in x-direction

Reference Degree of Slenderness in x-direction

(Pt. 1, Ch. 8, Sec. 5 / [2.2.2])

Substituting values:

Reduction Factor for Stress in x-direction

(Pt. 1, Ch. 8, Sec. 5 / Table 3)

Case 2:

- Parameters:

Reference Degree of Slenderness in Y Direction λᵧ

(Pt. 1, Ch. 8, Sec. 5 / [2.2.2])

Factor

(Pt. 1, Ch. 8, Sec. 5 / [2.2.3])

The coefficient was calculated appropriately to chosen the SP-A assessment method:

- Substituting:

Calculation of

Calculation of

Calculation of

Reduction Factor for Stress in Y Direction

(Pt. 1, Ch. 8, Sec. 5 / Table 3)

- Substituted values:

Case 15:

- Substituted values:

Reference degree of slenderness in direction

(Pt. 1, Ch. 8, Sec. 5 / [2.2.2])

- Substituted values:

Reduction factor for stress in direction

(Pt. 1, Ch. 8, Sec. 5 / Table 3)

- Substituted values:

Ultimate buckling stresses

(Pt. 1, Ch. 8, Sec. 5 / [2.2.3])

- In the direction parallel to the longer edge of the buckling panel:

- In the direction parallel to the shorter edge of the buckling panel:

- Shear:

The rest of the input parameters for final equations were calculated:

- Plate slenderness parameter

(Pt. 1, Ch. 8, Sec. 5 / [2.2.1]):

Coefficient

(Pt. 1, Ch. 8, Sec. 5 / Table 1):

Coefficient

(Pt. 1, Ch. 8, Sec. 5 / Table 1):

Final Equations for Limit States

(Pt. 1, Ch. 8, Sec. 5 / [2.2.1]) — Transformed to calculate stress multiplier factors acting on loads

I.

II.

III.

IV.

Partial Safety Factor and Stress Multiplier Factors

The partial safety factor

(Pt. 1, Ch. 8, Sec. 5 / Symbols) was set as:

Then the values of stress multiplier factors acting on loads

were calculated:

I.

II.

III.

IV.

Minimum Stress Multiplier Factor and Utilization Factor

The minimum stress multiplier factor from above – the stress multiplier factor at failure – was found:

The utilization factor was calculated (Pt. 1, Ch. 8, Sec. 1 / [3.2.2]):

SDC Verifier Setup

In SDC Verifier, the standard was added using the same assumptions as in the analytical calculation. The check was then performed based on this setup.

1. Mild Steel Properties

Top Plate Properties (T = 12 mm)

Properties Summary

Calculated for the CSys “0..Basic Rectangular”

FEM Loads

This paragraph contains information about applied loads to model.

1. Long edges

2. Short edges

3. Long edges parallel

Constraints

This paragraph contains information about constrained parts of the model.

Results

1..Job 1

Load Sets

In this paragraph, the influence of the different load combinations is described.

Load Set ‘1..Load Set 1’

3..LR CSR Plate Buckling (2024)

Standard implemented according to LR Common Structural Rules for Bulk Carriers and Oil Tankers, January 2024 based on the following part of the standard Part 1, Chapter 8 – Buckling

Unit System

Current Unit System = MKS (Meter/Kg/Second). It is used in calculations for the following standards:

API RP 2A, ISO 19902, Norsok N004, DIN 15018, FEM 1.001 and Eurocode3.

Intermediate Results of σ′cx, σ′cy and τ′c from Calculation Details of the Check

Comparison of Hand Calculations and SDC Verifier Results

| Parameter | Hand Calculations | SDC Verifier |

| Slenderness Requirement | Passed | Passed |

Ultimate Buckling Stresses [MPa]

| Parameter | Hand Calculations | SDC Verifier |

| σ′cx | 119.145 | 119.252 |

| σ′cy | 58.750 | 58.631 |

| σ′c | 92.932 | 92.585 |

Inverse of Stress Multiplier Factors Acting on Loads

| Parameter | Hand Calculations | SDC Verifier |

| 1/γc1 | 0.567 | 0.562 |

| 1/γc2 | 0.402 | 0.396 |

| 1/γc3 | 0.508 | 0.504 |

| 1/γc4 | 0.177 | 0.169 |

Utilization Factor

| Parameter | Hand Calculations | SDC Verifier |

| ηact = 1 / γc1 | 0.567 | 0.562 |

Note: Results from SDC Verifier are the same as those obtained with hand calculations.

Conclusion

The benchmark confirms a high level of agreement between hand calculations and the automated SDC Verifier check:

-

The slenderness requirement was satisfied.

-

Differences in ultimate buckling stresses and stress multiplier factors were within <0.2%, indicating precise consistency.

-

The utilization factor obtained was nearly identical:

→ Hand calculations: ηact = 0.567

→ SDC Verifier: ηact = 0.562

This validation demonstrates that SDC Verifier accurately implements the LR CSR 2024 buckling assessment procedures, making it a dependable tool for structural integrity checks in maritime and offshore applications.