Multi-Standard Compliance: Why Following Every Code Might Be Holding You Back

For experienced engineers, compliance is more than a box to check — it’s a responsibility to ensure structural integrity under real-world conditions.

But what happens when a single model needs to satisfy multiple standards, each demanding its criteria? The traditional approach wastes time and risks inconsistency with duplicated models and redundant analyses.

Integrated compliance management changes this, allowing engineers to meet diverse standards in a unified model without compromising accuracy or efficiency.

Defining Multi-Standard Compliance Requirements in Complex Structures

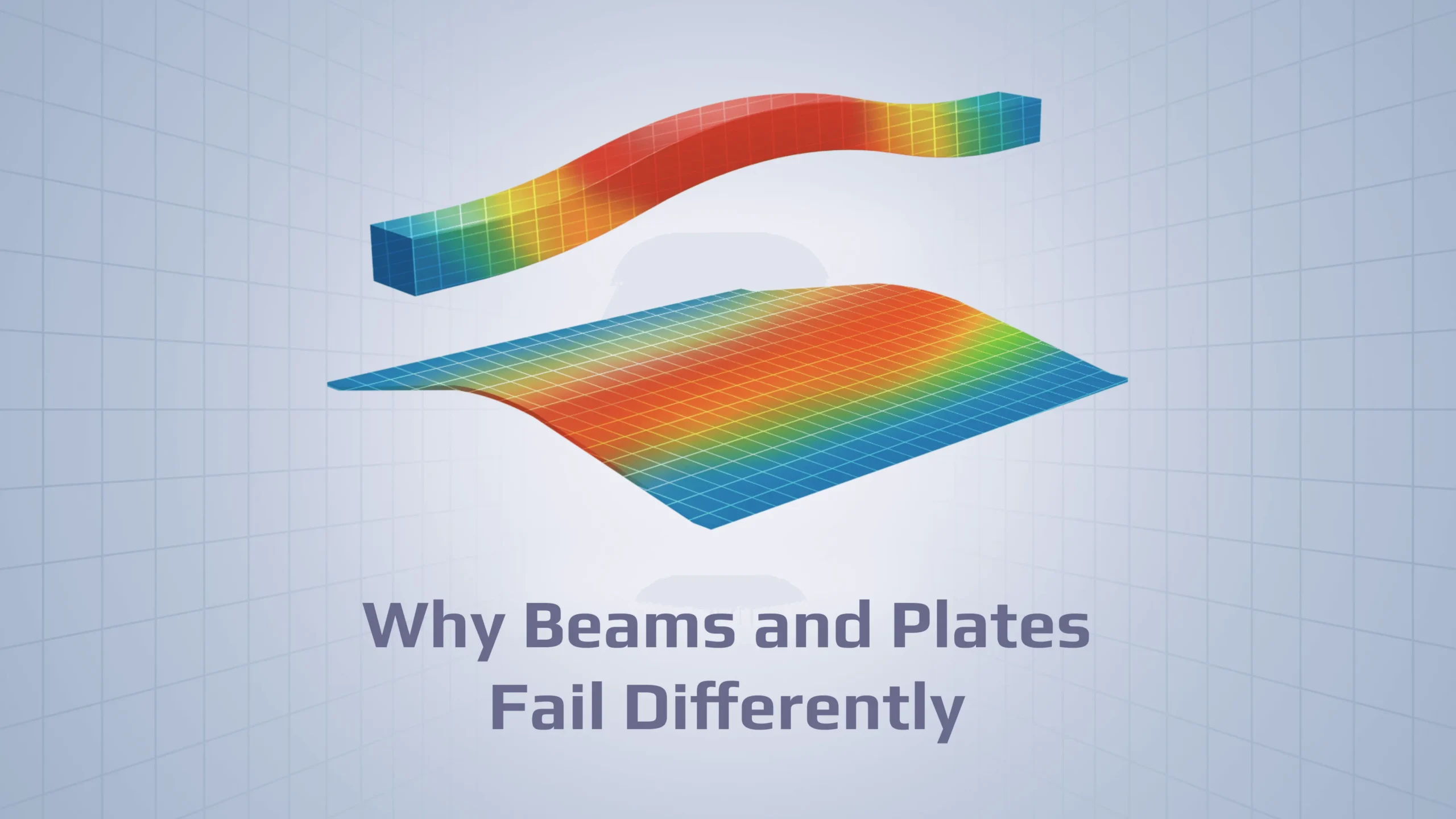

Multi-standard compliance in engineering isn’t a one-size-fits-all process; each structural element within a model — whether it’s a plate, tubular shape, or beam — presents unique requirements dictated by its material properties, geometry and functional role. For instance, flat plates may demand stringent buckling checks, tubular shapes require specific load distribution assessments, and beams often need verification for lateral-torsional buckling and cross-sectional strength.

Managing these varied checks within a single model rather than isolating them into separate analyses not only reduces redundancy but also provides a cohesive view of structural integrity. This unified approach ensures that each part is evaluated according to the specific standard relevant to its function while maintaining consistency across the entire model. The question then arises: Can this be accomplished effectively within one model?

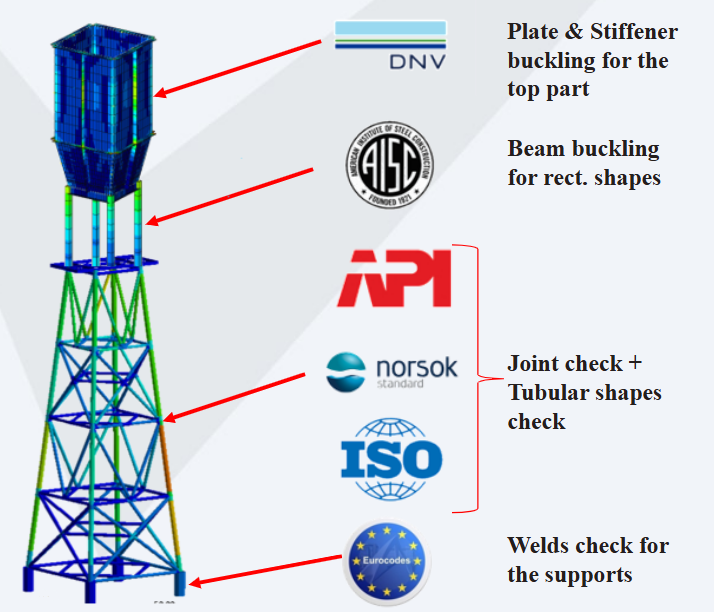

The image below illustrates this concept with a structural tower model. Different sections are assigned distinct standards based on their specific geometry and compliance needs. Each part, from the top plate and stiffeners to the supporting welds, is evaluated according to the appropriate standard, demonstrating the practicality of multi-standard compliance within a single model.

Example of multi-standard compliance within a single structural model, showing how different parts meet distinct regulatory requirements.

With an integrated compliance system like SDC Verifier, engineers can apply distinct standards to different components in a single analysis framework. This approach significantly streamlines the process, minimizing model duplication and re-analysis, and allows engineers to focus on optimizing designs rather than reconciling isolated results. Ultimately, a unified model for multi-standard compliance enhances workflow efficiency, accuracy, and traceability across the engineering lifecycle.

A Unified Approach: Streamlined Load and Rule Applications

A unified approach to multi-standard compliance requires load management and rule application flexibility. Rather than recreating models for each set of requirements, engineers can use pre-defined loads across various standards, adapting them to specific parts of the structure as needed. This flexibility allows for a single model setup that can accommodate diverse load cases, eliminating the inefficiencies of model duplication.

Beyond load management, rule customization for structural components is crucial in meeting compliance across different sections. By applying specific compliance rules to individual elements — whether plates, beams, or tubular sections — engineers can tailor checks to the precise requirements of each component without disrupting the overall model integrity. This adaptability within a single model enables seamless integration of multiple standards, reducing manual adjustments and ensuring that each part is evaluated according to its unique compliance criteria.

The result is a streamlined compliance workflow where all structural parts operate within one cohesive analysis. This approach saves time and enhances accuracy by maintaining a unified, consistent model that aligns with varied regulatory requirements across the entire structure.

Comparison of Traditional vs. Unified Compliance Management

Managing multi-standard compliance traditionally involves creating separate models for each applicable standard, performing redundant checks, and manually reconciling results. While this approach has been the industry norm, it often leads to inefficiencies and inconsistencies. SDC Verifier’s unified compliance system offers a transformative alternative by consolidating these tasks into a single streamlined workflow.

| Aspect | Traditional Approach | Unified Approach (SDC Verifier) |

|---|---|---|

| Model Creation | Requires separate models for each standard. | A single model accommodates all standards. |

| Load Application | Loads must be manually recreated across multiple models. | Predefined loads are applied consistently across all standards. |

| Analysis Redundancy | Re-analysis required for each standard. | Single analysis handles all standards simultaneously. |

| Cross-Referencing Standards | Manual referencing between standards, prone to errors. | Built-in cross-referencing ensures seamless integration. |

| Time Investment | Significant due to repeated tasks and model management. | Reduced by up to 40% through automation. |

| Resource Efficiency | High computational and human resource demands. | Optimized use of resources, cutting redundancy by ~50%. |

| Traceability | Results scattered across multiple models. | Centralized results for easier tracking and verification. |

Switching to a unified compliance management approach not only simplifies workflows but also enhances the reliability of compliance processes, making it an indispensable tool for engineers working with complex multi-standard models.

Cross-Referencing: Utilizing Integrated Standards for Efficiency

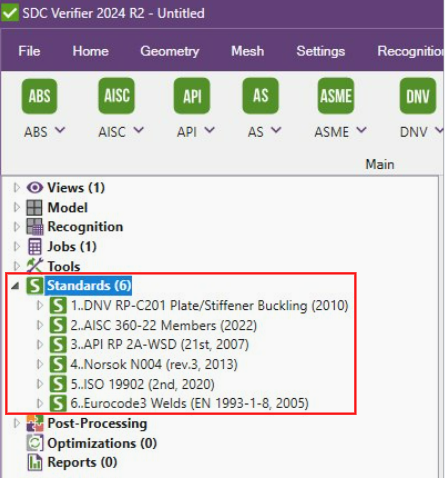

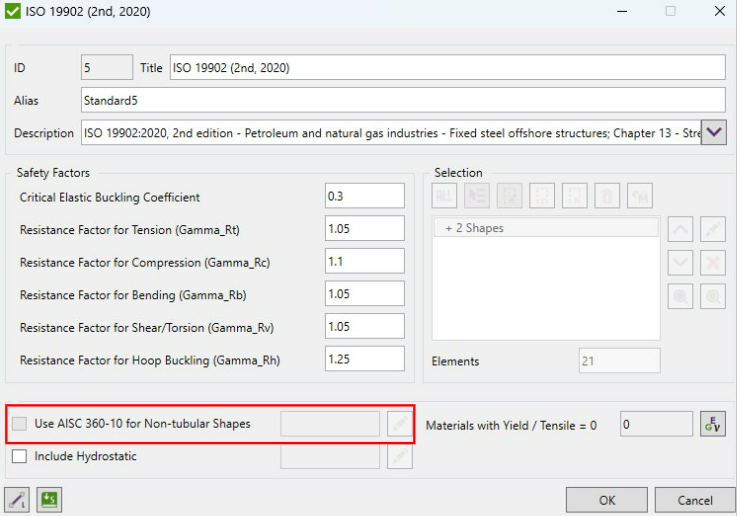

Cross-referencing functionality within an integrated compliance framework is essential for bridging the gaps between different codes in multi-standard compliance. This capability allows engineers to apply one set of standards while seamlessly referencing supplementary requirements from related codes. For example, engineers can simultaneously incorporate AISC standards for non-tubular shapes without needing separate analyses when ISO standards are used for tubular structures. This cross-referencing feature enables SDC Verifier to streamline complex compliance workflows.

The image below demonstrates how the SDC Verifier organizes multiple standards within a single model, showing the flexibility to apply compliance checks from various standards across a single project. By managing interdependencies between codes, the software reduces redundant steps and enhances workflow efficiency, allowing engineers to meet diverse regulatory requirements cohesively.

|

|

Standards configuration in SDC Verifier, enabling efficient cross-referencing and management of multiple codes within a single model; Cross-referencing additional standards in SDC Verifier, enabling integrated compliance checks for specific structural requirements.

This integrated approach not only saves time but also minimizes the risk of overlooked requirements, providing a comprehensive and efficient compliance process. The result is a more intuitive and cohesive model, where each structural element meets multi-standard requirements within a unified analysis environment. This efficiency is crucial in complex models, ensuring that all relevant checks are systematically addressed without disrupting the continuity of the compliance process.

Comparative Compliance Analysis: Finding Optimal Solutions

Comparative compliance analysis is a critical tool for engineers managing multi-standard models. It allows for a systematic comparison of compliance outcomes across various standards. By examining the “worst” and “best” results generated from different standards, engineers can pinpoint the most stringent criteria, ensuring that the model meets or exceeds the highest safety and reliability requirements without unnecessary re-analysis.

The image below demonstrates how SDC Verifier enables this process, allowing engineers to configure comparative standards — such as API, NORSOK, and ISO — for an overall utilization check. This setup allows engineers to directly evaluate and compare results across multiple standards, helping identify the strictest compliance measures for each part of the structure without redundantly applying each standard independently.

Comparative compliance setup in SDC Verifier, enabling engineers to evaluate and compare standards like API, NORSOK, and ISO for overall compliance.

This functionality is particularly valuable when multiple standards apply to the same structural component but have differing thresholds or failure limits. Comparative tools allow engineers to consolidate these variations, highlighting the most demanding compliance measures within a unified framework. This approach mitigates risks across the model while avoiding redundant re-analysis, ensuring critical safety thresholds are met efficiently.

Ultimately, comparative compliance analysis provides a streamlined yet rigorous approach, enabling engineers to make informed decisions on compliance priorities without compromising structural integrity. By focusing on the most stringent standards, engineers can reduce rework and optimize compliance management, maintaining high levels of safety and reliability throughout the structure.

Selective Analysis to Manage Computational Load

In large-scale engineering models, the computational load can quickly become a limiting factor, especially when multiple compliance checks are required. Selective analysis addresses this by allowing engineers to isolate specific regions of a model for targeted compliance verification without subjecting the entire structure to re-analysis. This capability is invaluable for focusing on high-priority or complex areas, such as critical joints or load-bearing components, where compliance demands may be more intensive.

By applying localized checks, engineers can significantly reduce computation times, optimizing resources while maintaining the integrity of the analysis. This approach minimizes unnecessary processing on sections that may not require immediate evaluation, ensuring that only essential areas undergo detailed compliance assessment. As a result, selective analysis accelerates compliance checks and enhances model manageability, providing a strategic solution to computational constraints in multi-standard environments.

Streamlining Compliance with SDC Verifier

SDC Verifier’s single-model approach to multi-standard compliance simplifies complex regulatory demands, allowing engineers to apply multiple standards within one cohesive framework.

With tools for cross-referencing, comparative analysis, and targeted checks, SDC Verifier enhances efficiency and precision, reducing redundant analyses and streamlining the compliance process.

For engineers looking to improve accuracy and workflow, SDC Verifier provides a powerful solution that turns compliance from a burden into a seamless part of the engineering process.