LNG Tank Support Verification for Spain’s First LNG Bunkering Vessel

100%

Compliance BV NR467 (ULS/ALS)

4×

Finer mesh in critical zones

0%

Rework and class approval on first pass

- CESAC used SDC for Femap to validate LNG tank saddles and the double-bottom structure, ensuring safe load transfer and class compliance on the Haugesund Knutsen.

- Modeling included bilobe tanks, refined shell mesh, and nonlinear GAP contacts, with checks run to Bureau Veritas NR467 for ULS and ALS.

- Results: stresses remained below allowable limits and buckling stability was confirmed, including 30° heel and ±0.5 g collision scenarios.

Project Background

The LNG Haugesund Knutsen, owned by the shipping company Knutsen OAS and built at Astilleros Armón Gijón, is the first liquefied natural gas (LNG) bunkering and transport vessel designed in Spain. Its mission is to foster the development of LNG as a sustainable marine fuel and to ensure reliable supply in ports, in line with the EU Alternative Fuels Directive.

CESAC, a company specialized in the design and structural analysis of marine and offshore structures, was entrusted with the structural verification of the cargo hold where the LNG tanks and their supporting saddles are integrated. To ensure accuracy, safety, and compliance with Bureau Veritas class rules, CESAC used SDC for Femap software.

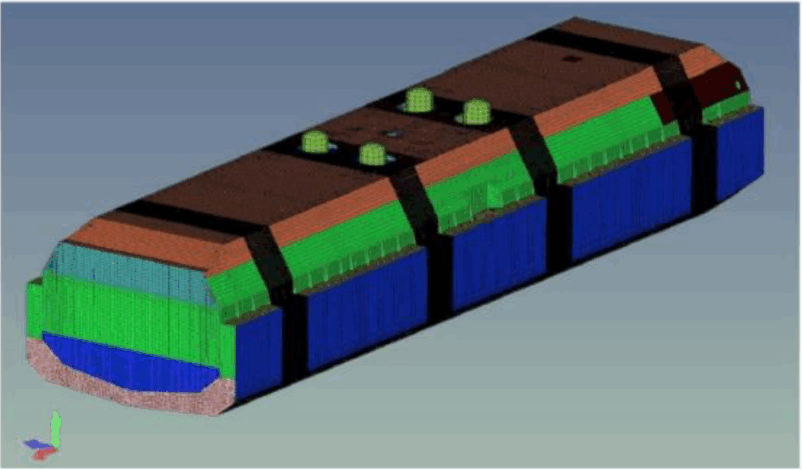

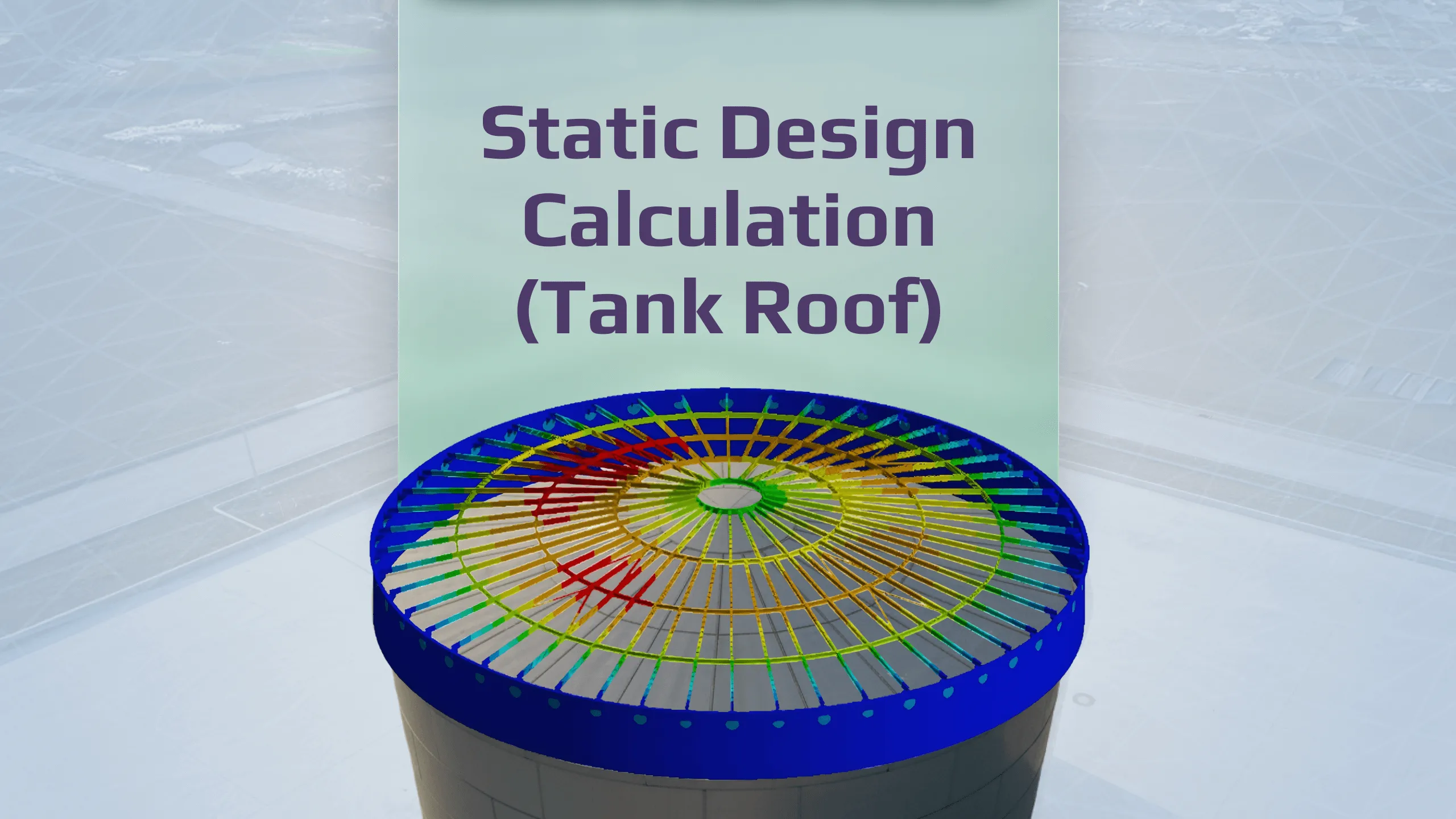

Figure 1. Finite Element Analysis (FEA) model of the LNG Haugesund Knutsen cargo hold and tank support structure.

Vessel and Cargo System Description

The vessel has principal dimensions of 91.9 m length overall, 16.90 m breadth, and 4.25 m draft, and is equipped with a storage capacity of 5,000 m³, consisting of two bilobe tanks of 2,500 m³ each, with an LNG supply capacity of 1,000 m³/h.

The cargo area is bounded by a forward bulkhead at frame #120 and an aft bulkhead at frame #18. A transverse bulkhead at frame #69 divides the two cargo holds, defining Tank No. 1 forward and Tank No. 2 aft.

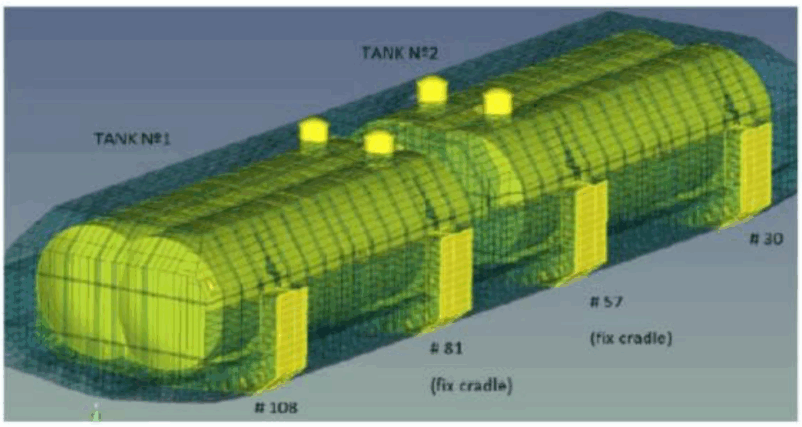

Figure 2. Finite Element model of LNG Haugesund Knutsen showing bilobe tanks, fixed and sliding saddles aligned with vessel frames.

Each tank is a Type-C bilobe LNG tank, 28.4 m in length, with a light weight of 240 metric tons and a cargo weight of 1,140 metric tons. With a cylindrical geometry, the tanks are also equipped with anti-collision and anti-flooding devices.

The tanks are supported on two high-strength wooden saddles (350 mm thick), aligned with frames #30, #57, #81, and #108. One saddle acts as a fixed support, restraining longitudinal movement, while the other allows sliding, enabling controlled deformation and reducing the risk of tank damage. These saddles are designed to transfer tank loads into the double-bottom structure.

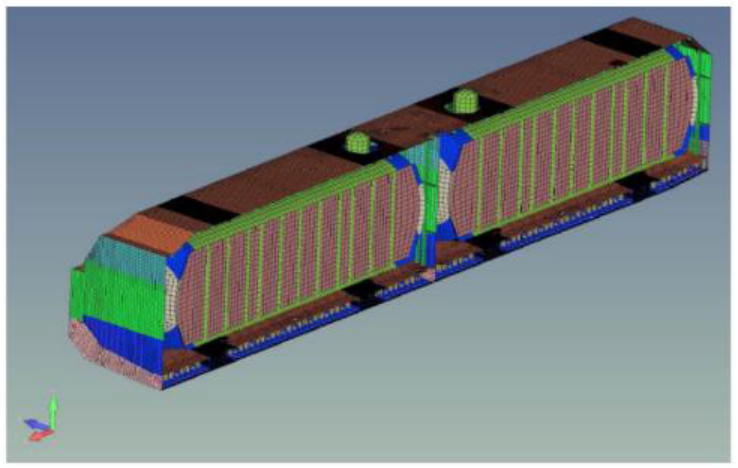

Figure 3. FEA model of LNG Haugesund Knutsen showing bilobe tanks integrated with the supporting structure in the double bottom region.

Analysis Methodology with SDC Verifier

To capture the structural behavior, the bilobe tanks were explicitly modeled within the FEA analysis. This ensured correct representation of structural stiffness and the accurate transmission of reaction forces from internal tank loads to the saddles and into the surrounding support structure — including web frames, longitudinals, and floors of the double bottom.

The cargo compartments were meshed using CQUAD4 four-node shell elements with a base mesh size of 200 × 200 mm. In saddle areas, where stresses concentrate, the mesh was refined to 50 × 50 mm. This refinement allowed CESAC to carry out detailed local analysis in the most critical zones.

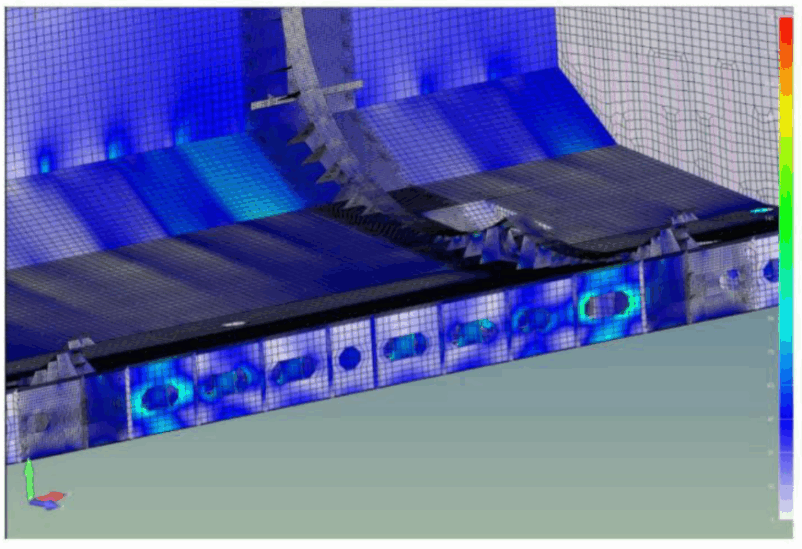

Figure 4. Stress distribution in the saddle region of LNG Haugesund Knutsen cargo hold model, highlighting areas of highest stress concentration.

How it was done in SDC Verifier

-

Model & selections. The imported Nastran model was organized in SDC for Femap. Panel Finder auto-recognized double-bottom plating (floors, longitudinals, web frames). Named selections mapped the saddle zones at frames #30, #57, #81, #108 for focused checks.

-

Loads & combinations. Using the Load/Combination Manager, Permanent (tank self-weight), Environmental (external sea pressure, accelerations) and Tank loads were grouped and combined per BV NR467 into ULS and ALS sets, including 30° heel and ±0.5 g longitudinal collision.

-

Plate stability (buckling) & stresses. Plate Buckling checks were run on panels in the saddle vicinity and double bottom. BV NR467 clauses not present in the library were implemented via the Custom Rule/Formula Editor. Governing hot-spots were located with Extremes on the 50 × 50 mm refined mesh.

-

Reporting. With Report Designer, CESAC produced an auditable package: load sets and combinations, panel lists, pass/fail tables for stresses and plate stability, and figure exports (mesh refinement and saddle hot-spots).

-

Contact note. Nonlinear contact between the tanks and the hull was solved in the FE solver; SDC Verifier imported these results and performed BV NR467 checks (ULS/ALS).

Accidental Scenarios

For ALS, the following scenarios were evaluated: 30° heel and ±0.5 g longitudinal collision (both directions), with the collision case focusing on the fixed saddle that carries the longitudinal impact.

The nonlinear contact analysis (opening/closing and sliding at the tank–hull interface) was solved in the FE solver. SDC Verifier then imported the solved stress/resultant fields and performed BV NR467 checks (ULS/ALS), including plate-stability (buckling) verification and pass/fail reporting.

Results and Verification

The analysis performed with SDC Verifier confirmed that:

- All stresses in saddles and supporting structures were below maximum allowable values defined by Bureau Veritas.

- Buckling stability of plates was verified, both in saddles and double-bottom structural elements.

- Under longitudinal direction checks, global bending moments due to hogging and sagging were included, ensuring conservative evaluation.

- The fixed saddle successfully absorbed collision impact (0.5 g), validating its role in accidental scenarios.

- The use of sliding supports was confirmed to be effective in absorbing deformations and preventing tank damage.

Project Impact

Using SDC for Femap for automated code checks, plate-stability evaluation, extremes detection, and reporting, CESAC created a traceable, class-oriented verification package covering normal and accidental conditions with realistic contact behavior. The workflow consolidated loads → combinations → pass/fail checks → report in one environment and aligned directly with Bureau Veritas expectations.

As the analysis identified local hot-spots near the saddles, CESAC implemented targeted reinforcement/redesign and re-evaluated the model; after the update, the evaluated panels met BV NR467 acceptance criteria (ULS/ALS).

This approach is repeatable for LNG bunkering vessels and other marine/offshore projects with Type-C tanks and saddle-based supports.

A related technical report by CESAC on this topic was published in Revista Ingeniería Naval (Spanish edition).