Optimization is a function of the FEA environment that enables the development of the most cost-effective structural model. In addition, it helps to save material and ensures industry standards compliance. With the help of optimization, the engineer can define the best possible design, reduce the material quantity, prevent stress concentrations, remove bottlenecks, and attain desirable performance attributes.

Types of optimization in FEA

There are two approaches for optimization – parametric and non-parametric. With parametric – the natural shape is automatically detected by software to pertain to heavy loads carrying capabilities while keeping the costs at a minimum. The major advantage of this approach is that modeling can be started from scratch without any original design. Suppose the best design must be chosen relative to the starting point. In that case, several vital parameters or design variables need to be selected, and an allowable range for each needs to be defined. Then parametric approach is used where each parameter is varied within the permissible range to find the optimal design. Similarly, the structural metrics are optimized while minimizing the final volume.

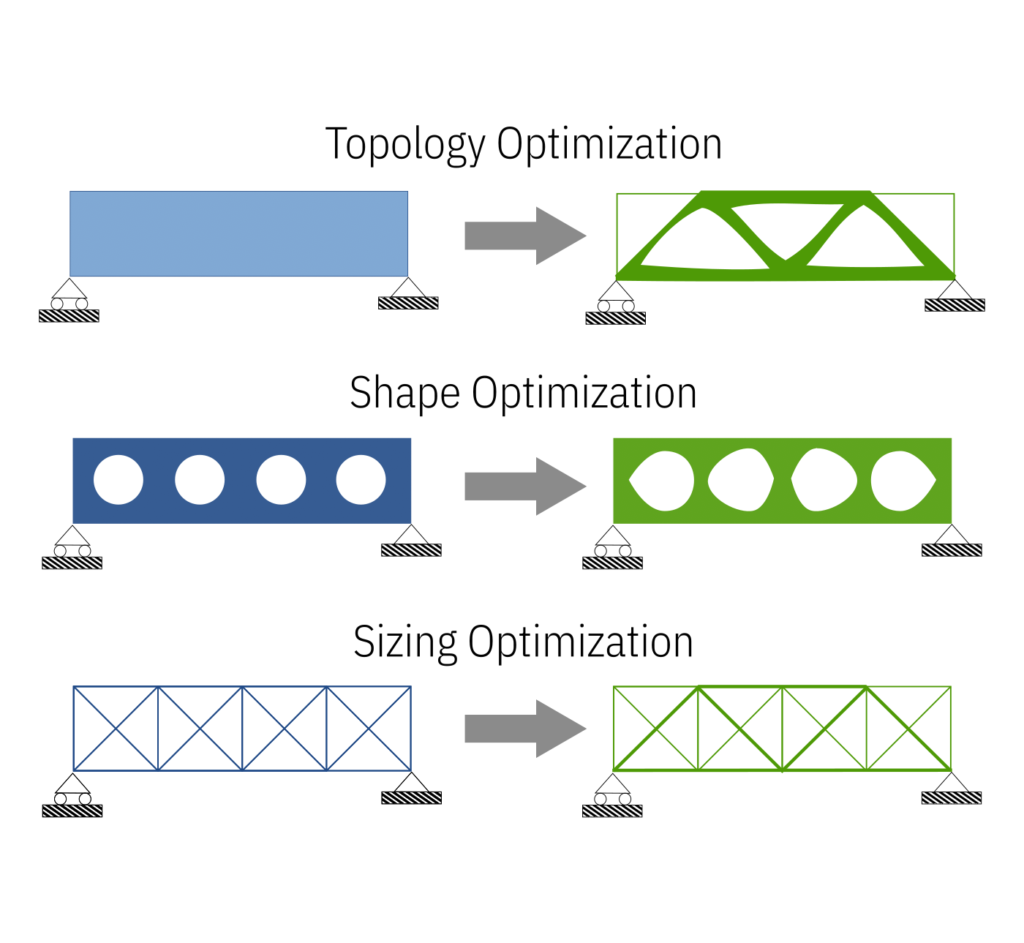

Optimization in finite elements is also classified by methods either based on optimizing grid locations (shape optimization), geometric properties (sizing optimization), or material properties (material optimization).

Topology optimization

A particular case of material optimization with element material fractions between 0 and 1 is topology optimization – a mathematical method used at the concept level of design development. This method aims to spread the amount of material present more effectively over the model and minimize the strain energy.

It considers the boundaries set by the designer, applied load, and space limitations to create a design.

Results emerging from topology optimization are often fine-tuned for manufacturability. While carrying out the material distribution, the objective function does not consider aesthetics or the ease of manufacturing.

The most attractive benefit of topology optimization is its ability to reduce unnecessary weight. Size optimization means that less raw material is needed. All these advantages translate directly into actual cost savings, which is essential in a competitive market.

Shape Optimization

Shape optimization assures picking the best possible structure geometry to improve the desired mechanical behavior respecting some constraints. Moreover, with the help of automated design optimization tools, engineers can look for creative solutions that are not obvious to even the most experienced specialists, particularly in the shape optimization problems with potentially hundreds of design variables.

Shape optimization tools estimate the effects of simultaneously modifying numerous design parameters considering not just straightforward dimensional changes but general changes in shape.

Topology optimization normally involves linear static finite element assumptions, while shape optimization involves linear and nonlinear finite element analysis.

Sizing Optimization

Panels, beams, and joints can be sized throughout the design phases. Sizing optimization (or cross sections’ and thickness properties of finite elements optimization) reduces the weight of many different materials and panel concepts, producing consistent and producible designs.

Due to the easy calculation of the sensitivities for sizing optimization purposes, even the most complex problems can be handled.

Benefits of Automatic Structure Optimization

Automatic structural optimization helps to find the optimal design solution, which is a very challenging task to achieve. It helps check simultaneously numerous structure elements (beams, plates, welds) for compliance to standards. It provides engineers with many options of the model modification. Even though the benefits of optimization tools are well recognized, these tools are not yet efficiently integrated into practicing engineers’ design workflow. Optimization and structural analysis tools are effectively used to provide structural engineers with supplemental design information.

Structural Optimization in SDC Verifier

SDC Verifier Optimization Tool allows design decisions based on code-checking and combines all the power of automatic optimization. The general idea of the Optimization Module is to check the design, so that element properties meet industry standards. Without the optimization module, only a situation check is possible, whether some values fulfill the requirements or not. To speed up the process, it is worth taking the first governing load set and then reducing the total number of load sets into a relevant one, in order to use only important loads and reduce the calculation process to a fraction of the original calculation time. Instead of one single design, the best design decision for the structure is taken by calculating different combinations of design input.

Optimization of Beam Members

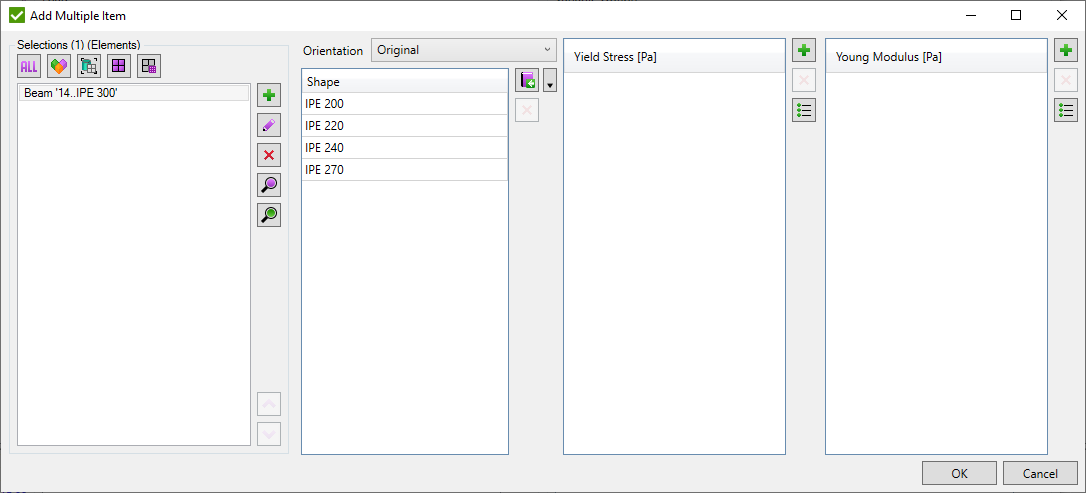

Optimization lets engineers make extra analyses, e.g., a set of possible member sizes and shapes for each part of the model with the most economically applicable member or selection of members. Therefore, instead of a straightforward model, SDC Verifier checks for each selection or whether it is a component or a material.

For all beam members, SDC Verifier can decide which shape is the most optimal based on the maximum stress results or utilization factors according to applicable standards. The app comes with the best solution, instead of recalculating that new shape, and automatically updates the design with the optimized values to decrease weight or comply with regulations.

This is achieved through the Beam Section Optimization tool that provides the automation and required options for the model optimization. We then proceed with a beam section optimization case to reduce the model complexity and size to achieve faster analysis while maintaining the model’s stiffness and structural behavior.

Beam Rule is used to optimize beam or bar element’s cross section, yield stress, Young modulus. It is typically used for beam members verification, including buckling criteria prescribed by the standards. Beam Member Optimization is done according to Eurocode 3 Fire Design (EN 1993-1-2), Eurocode 3 Members Check (EN 1993-1-1), ISO 19902, Norsok N004, AISC 360-10 Members, AISC ASD 89 (9th, 1989), API RP 2A-LRFD (1st, 1993), API RP-2A WSD (21st, 2007), AIJ (2005 Edition, 2017), AS 3990 (1993).

Plates Optimization

Thin-walled components like plates are often in the design of light-weight structures because they are able to carry enormous loads compared to their relatively low self-weight. It is important to find balance between compliance to industry rules and costs of the structure (depends on plates width, thickness).

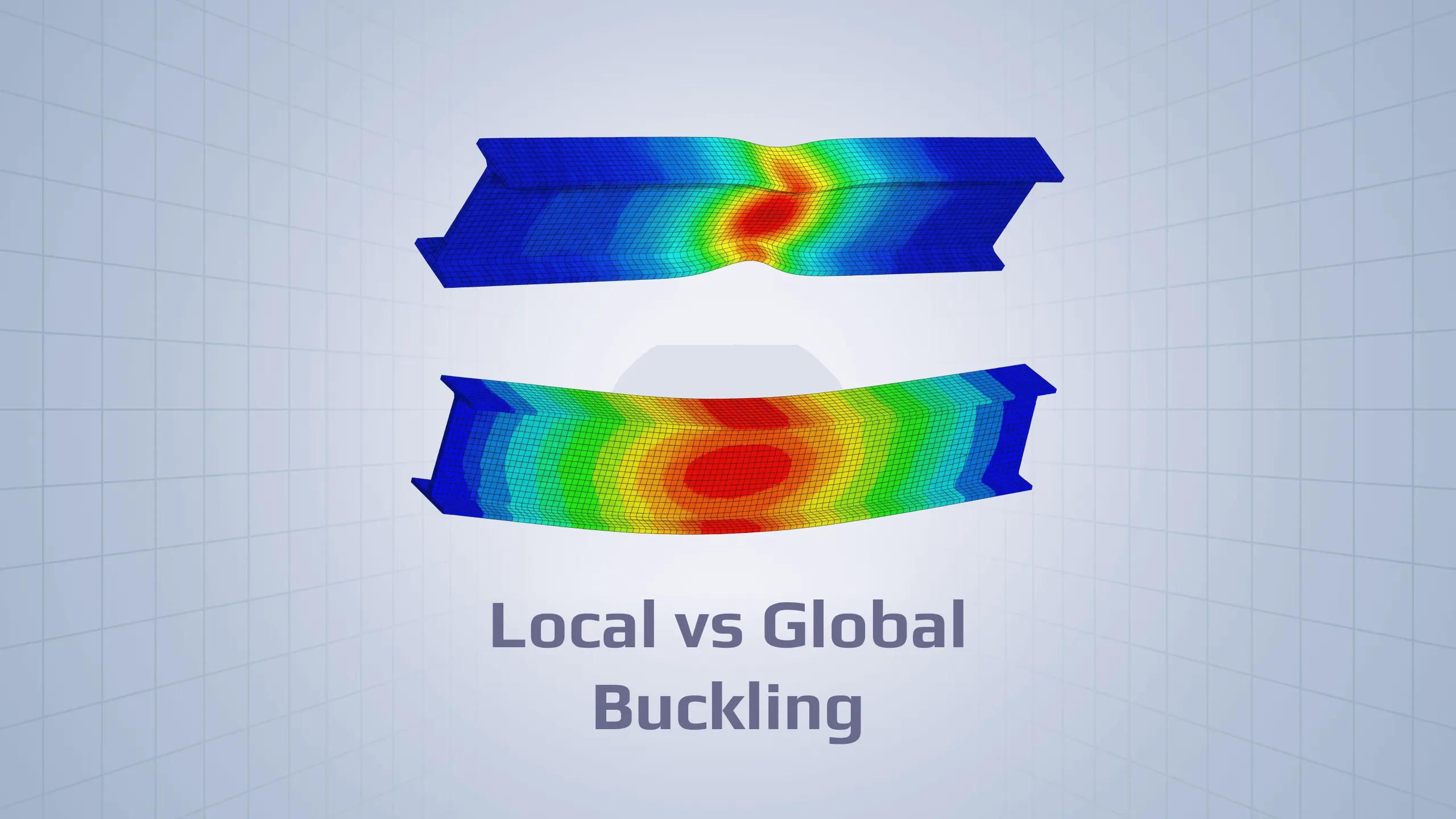

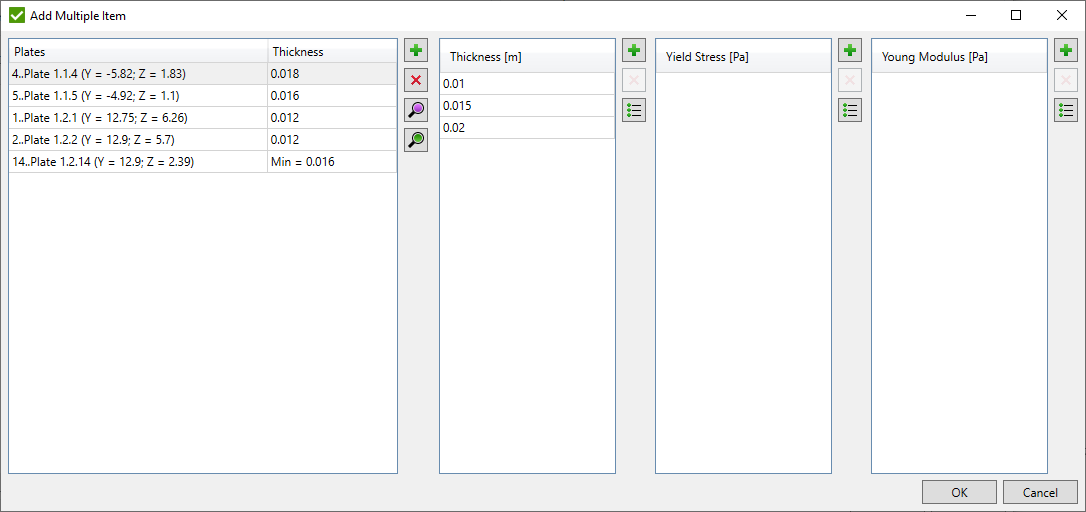

SDC Verifier Optimization Tool has two possibilities of plates optimization: Plate Element Rule and Plate Buckling Rule. Both Rules are used to optimize plate or shell element thickness, yield stress, Young modulus, but Plate Element Rule used to optimize plates according to fatigue standards and Plate Buckling Rules for plate buckling standards.

Plates can be optimized according to Plate Buckling Rules (ABS Plate Buckling (2004, 2014, 2022 and 2024), DNV CN30 Plate Buckling, DNV RP-C201, Eurocode 3 Plate Buckling (EN1993-1-5)) and Fatigue Standards (DIN 15018, DVS 1608 and DVS 1612, DNV-RP-C203 Fatigue. EN13001, Eurocode 3 Fatigue (EN1993-1-9), FEM 1.001, FKM (5th and 6th editions).

Welds Optimization

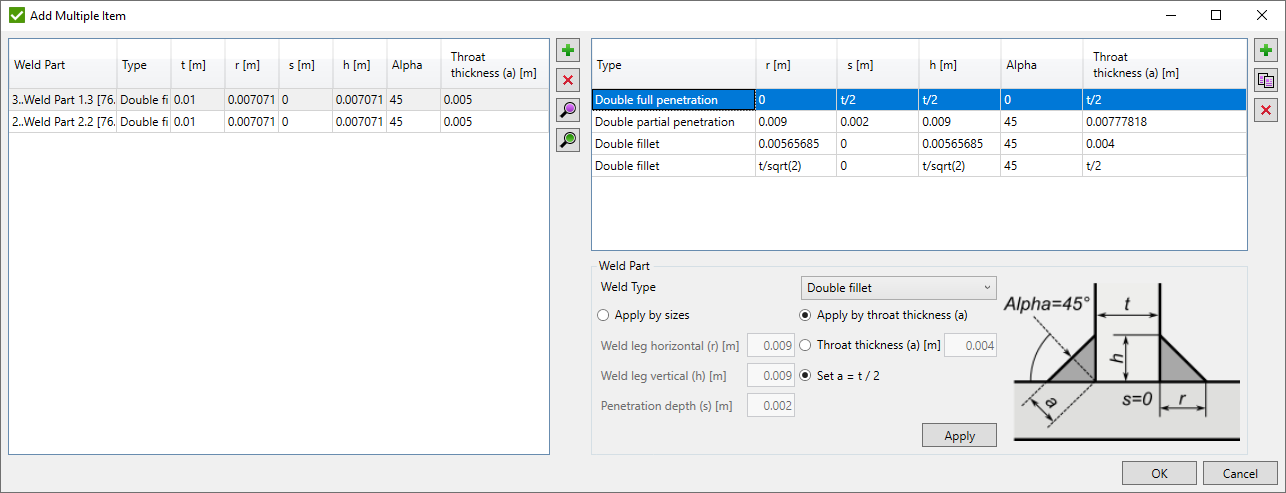

Weld Strength Rule is used to optimize weld parts weld type and dimensions (leg size, throat thickness etc.). It is typically used for weld strength standards. Welds can be optimized according to DNV OS-C101-LRFD, DNV OS-C201-WSD, Eurocode 3 Weld Strength (EN1993-1-8).

During the welds’ optimization, weld parts can be optimized according to main weld types:

- Double full penetration weld

- Double partial penetration weld

- Double fillet weld

After optimization, optimal weld part settings will be applied in Weld Finder Tool.

Summary

So, why is an FEA optimization so important? First, it helps to ensure that the structure overcomes all verification steps smoothly and corresponds to the standard requirements. At the same time, the complete process is done automatically and saves human time on intermediate iterations, especially if something should be changed. Also, it helps to find ways to reduce the structural weight and cost.

SDC Verifier software is capable of Beam, Plate, and Weld Optimization and all the benefits of automatic structural optimization. SDC Verifier Optimization Tool is a part of the SDC Verifier Enterprise level.