Structural Verification of Offshore Converter Platform Units

50%

faster strength verification vs. manual calculations

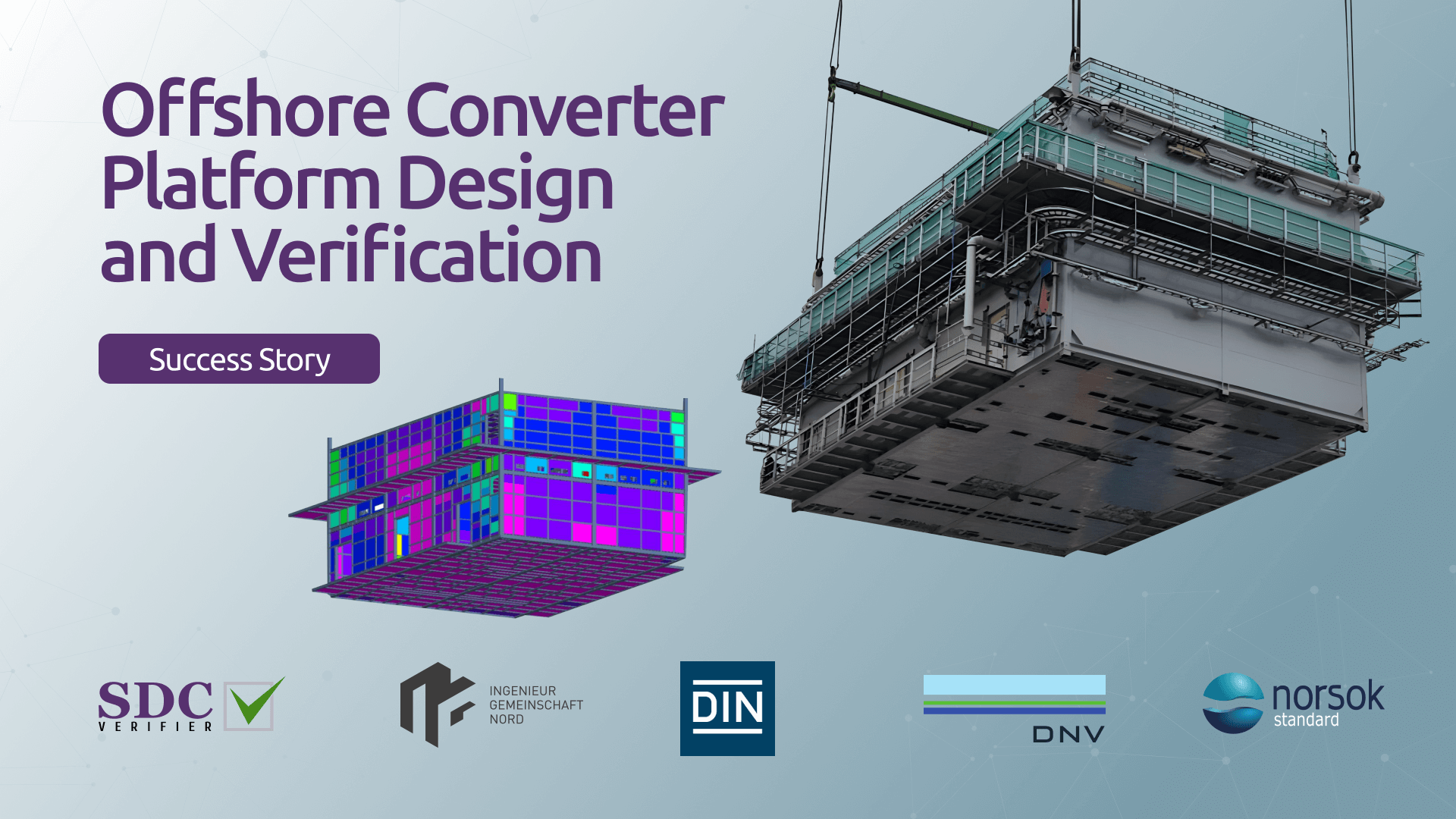

- The project covers structural design and verification of additional modules for an offshore converter platform.

- Automated FEA checks assess strength, plate buckling, and fatigue using SDC Verifier to meet DIN EN 1993-1-1, DNV RP-C201, and NORSOK N-004 standards.

- Results ensure safe lifting and operation while reducing verification time through streamlined compliance workflows.

Executive Summary

IGN-Ingenieurgemeinschaft Nord designed additional structural modules installed on the topside of an offshore converter platform, ensuring compliance with multiple engineering standards through precise strength verifications. Using SDC Verifier, the team streamlined member checks, plate buckling analysis, and fatigue assessments, ensuring compliance and efficiency.

The result: a fully validated, transport-ready structure delivered on schedule, with significant time savings in weld strength and fatigue evaluations.

The Challenge

IGN-Ingenieurgemeinschaft Nord was responsible for the structural design of additional modules installed on the topside of an offshore converter platform, including a large module supporting heavy components on two levels. This structure had to withstand transportation, lifting, and operational loads while meeting strict engineering standards.

Key Engineering Challenges:

- Complex Load Conditions – The module had to be designed for multiple load cases, including self-weight, lifting forces, and dynamic offshore conditions.

- Regulatory Compliance – The design needed to pass strength verifications based on DIN EN 1993-1-1 (member checks), DNV RP-C201 (plate buckling), and NORSOK N-004 (joint checks), requiring detailed assessments at every stage.

- Time Constraints – Given the offshore project timeline, structural analysis had to be both accurate and efficient to avoid costly delays in fabrication and installation.

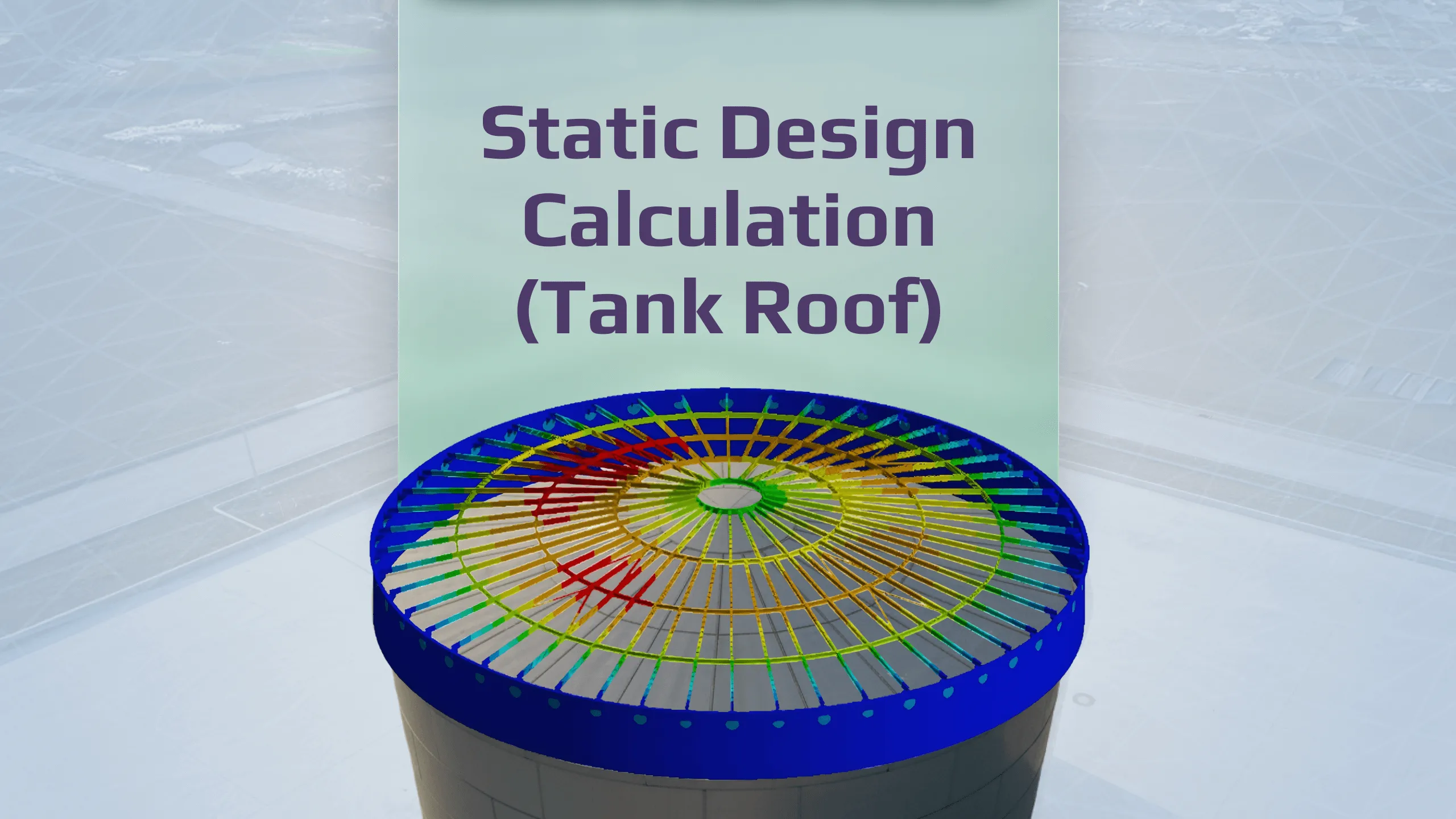

Image: Lifting and Installation of the Offshore Converter Platform Module (The structural unit, designed and verified by IGN Ingenieurgemeinschaft Nord, is lifted onto the platform’s topside. The verification process ensured its strength, stability, and compliance with offshore standards.)

Manual calculations or generic FEA tools would have significantly slowed the process, making it difficult to efficiently verify compliance across multiple engineering standards. A specialized solution was necessary to accelerate verification without compromising accuracy.

The Solution

IGN-Ingenieurgemeinschaft Nord used structural design and analysis software SDC Verifier to conduct structural verifications efficiently while ensuring full compliance with industry standards. The software enabled automated code checks, fatigue analysis, and strength verification of welds, members, and plates, significantly reducing manual effort.

Implementation Process:

- Preliminary Design & Load Assessment – Defined critical load cases, including lifting and operational conditions, to evaluate structural integrity.

- Automated Code Checking – Used SDC Verifier to perform:

- Member checks under DIN EN 1993-1-1

- Plate buckling analysis per DNV RP-C201

- Joint verifications in accordance with NORSOK N-004

- Fatigue & Weld Strength Analysis – Assessed fatigue life and verified welded connections, ensuring durability under cyclic offshore loads.

- Result Interpretation & Optimization – Identified high-utilization areas, refined design parameters, and ensured compliance with minimal iterations.

Image: Utilization Factors for Structural Members Based on DIN EN 1993-1-1 (This analysis visualizes the utilization factors of the offshore converter platform’s structural members. Higher utilization areas are identified for optimization.)

Image: Plate Buckling Analysis According to DNV RP-C201 (This visualization presents the buckling factor distribution across the structural unit. Critical areas are identified for further assessment and reinforcement.)

Why SDC Verifier?

- Speed & Accuracy – Automated reporting and direct integration with FEA reduced verification time.

- Transparency – Detailed code check calculations provided traceable, standards-compliant documentation.

- Seamless Compliance – Supported multiple industry codes in a single workflow, eliminating the need for separate manual checks.

This structured approach allowed IGN to finalize the design on schedule while maintaining engineering precision and regulatory compliance.

The Results

By integrating SDC Verifier, IGN-Ingenieurgemeinschaft Nord achieved faster validation, improved accuracy, and full compliance with offshore engineering standards.

Key Outcomes:

- Time Savings – Automated member, plate, and weld checks reduced verification time compared to manual calculations.

- Seamless Compliance – All DIN EN 1993-1-1, DNV RP-C201, and NORSOK N-004 checks were completed in a single workflow, eliminating redundant processes.

- Optimized Structural Performance – Identified and addressed high-stress areas early, ensuring the design met lifting and operational load requirements without overdesign.

- Clear, Traceable Documentation – Generated detailed calculation reports, streamlining the approval process.

Before vs. After Implementation:

| Metric | Before SDC Verifier | With SDC Verifier |

|---|---|---|

| Strength verification time | Required extensive calculations | Automated checks reduced workload |

| Compliance verification | Multi-standard checks required detailed assessments | Integrated verification |

| Weld strength assessment | Time-intensive process | Faster verification with automated checks |

| Report clarity | Detailed assessments required manual validation | Auto-generated, detailed |

This efficiency gain allowed IGN to meet project deadlines, minimize engineering effort, and ensure structural integrity with confidence.

Key Takeaways & Industry Impact

Lessons for Offshore Engineering

- Automated Code Verification Saves Time – Integrating SDC Verifier eliminated manual compliance checks, cutting verification time in half.

- Multi-Standard Compliance in One Workflow – Ensuring DIN EN 1993-1-1, DNV RP-C201, and NORSOK N-004 compliance without separate tools streamlined engineering workflows.

- Early Stress Identification Prevents Overdesign – Automated strength and fatigue analysis enabled targeted design improvements, balancing safety and material efficiency.

Impact on the Industry

This project demonstrates how automated engineering verification can improve speed, accuracy, and compliance in offshore structure design. For engineering firms handling complex load cases, the ability to rapidly validate structural integrity against multiple standards is a game-changer.

Firms adopting this approach can reduce engineering hours, simplify audits, and improve project predictability, setting a new standard for efficiency in offshore structural design.