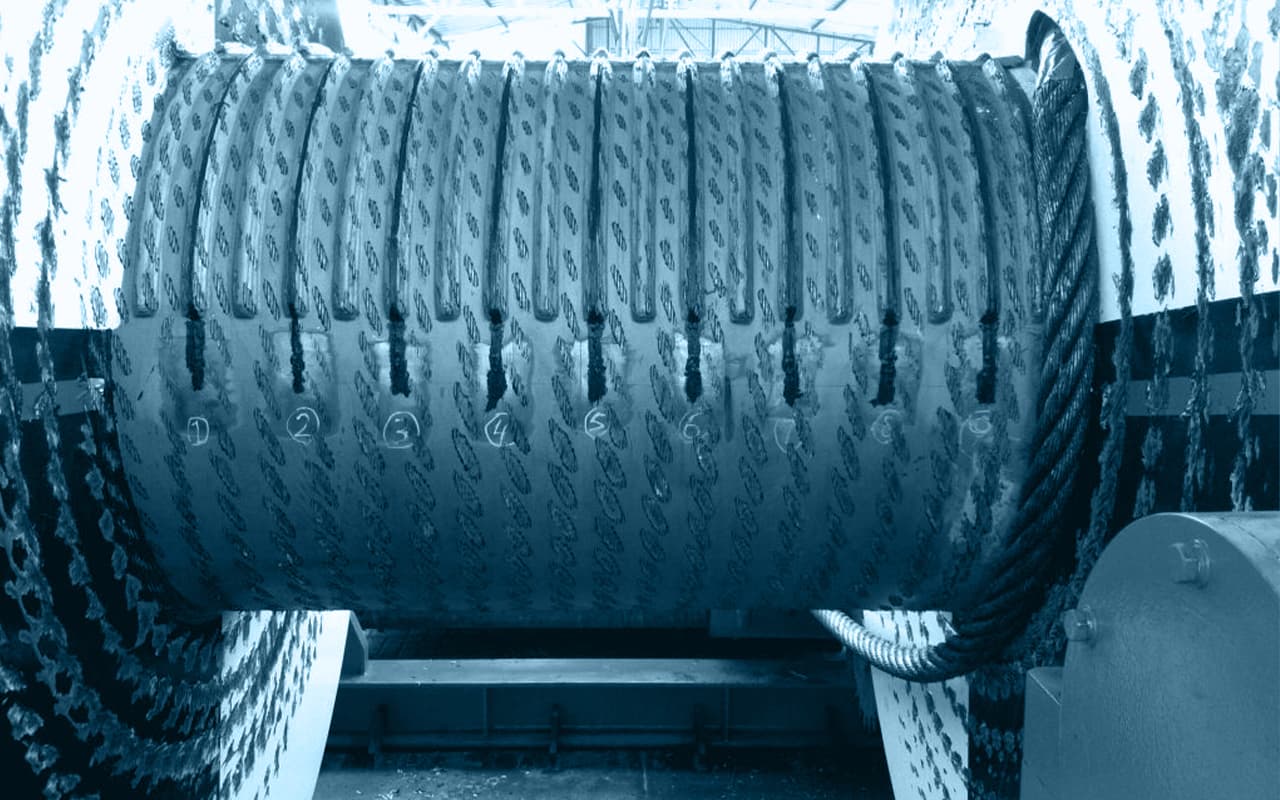

Bulk material conveyor

To investigate the premature idler support failure on an existing belt conveyor system, strain gauge measurements were taken together with the construction of three FEA models. A complete FEM model of the superstructure, to check the overall frame strength and a separate bend model to check the influence of the bulk material on the dynamic of the idler loads. After validation with the real life dynamic results from the strain gauges, the dynamic idler loads were determined and the origin of the premature support failure could be calculated with a detailed model of the idler support design. Before ordering new idler supports (+1000!), the dynamic behavior and the fatigue life of the new design were checked and optimized to find the most cost-effective solution and to avoid new expensive failures.