Strength assessment of the Cabin structure

An SDC Verifier Structural Engineering team analyzed the Cabin design of a multifunctional mechanical vehicle for compliance with the allowable loads and proposed design optimization to improve the ultimate strength.

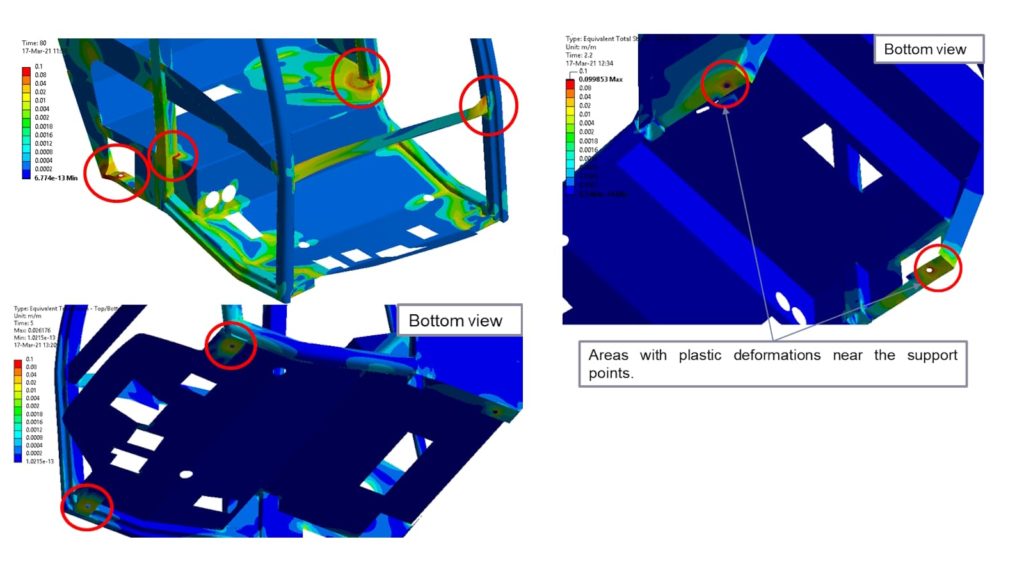

A non-linear analysis of the cabin behavior under different types of loads (lateral, longitudinal, and vertical) was performed to study the cabin dynamics.

Three-dimensional models were used to reproduce real-world conditions and dynamic interactions between structural elements accurately. As a result, the behavior of the cabin under each type of load was revealed, critical areas were identified, and options for optimizing the structure to meet the standards were proposed. The team used SDC Verifier, a robust finite element analysis (FEA) software solution, to combine the loads and verify compliance with industry standards.

In addition, the influence of different materials and their combinations on the strength of the structure was analyzed. This allowed the engineers to determine the optimal choice of materials, considering weight, cost, and functionality requirements.

As a result, a detailed project report was generated that included load plots, screenshots of critical areas, and tables of processed data. This report became a vital decision-making tool for optimizing the design of the cabin of a multi-functional mechanical vehicle.