How to Assign and Manage Materials in FEA Models?

One of the most critical steps in FEA modeling is the correct assigning materials and management of material properties. Material assignment and management in FEA software involves defining material properties and models for different elements or regions of a component’s geometry. Proper material assignment is crucial, as it affects the stiffness matrix, stress-strain behavior, and convergence, all of which influence overall simulation accuracy.

To achieve reliable results, it is essential to ensure that materials are assigned correctly, consistently, and comprehensively throughout the model. This article explores best practices for assigning and managing materials in FEA models in the example of SDC Verifier, ensuring precise simulations and optimal performance.

Materials Selection Process

When developing finite element models for stress analysis, it is essential to use the material models that will properly represent material from which structure will be created in real life. Even with identical geometry, loading conditions, and boundary constraints, each material responds differently due to its unique mechanical properties. Before completing the meshing, materials selection process involves several key steps:

- Define Design Requirements – Identify the necessary performance, reliability, size, cost, manufacturing, industry standards, regulations, intellectual property, and sustainability factors. The more requirements considered, the narrower the selection of suitable materials.

- Determine Selection Criteria – Establish specific material properties based on the design requirements. For example, if a component must withstand a certain load, the minimum yield strength becomes a critical criterion.

- Identify Candidate Materials – Use the selection criteria to filter out unsuitable materials. Consider the full range of material properties, including whether the material is

- Isotropic (uniform properties in all directions)

- Orthotropic (direction-dependent properties, like composites)

- Anisotropic (completely direction-specific properties)

- Evaluate Candidate Materials – If data is lacking for some materials, additional analysis or testing may be required to determine their suitability.

- Select the Best Material – Choose the material that meets all selection criteria at the lowest overall cost, factoring in both raw material expenses and manufacturing costs.

Moreover, standard materials are often prescribed by specific standards and regulations. Therefore, it’s essential to determine whether the structure must comply with certain rules and, if so, follow the relevant guidelines to select approved materials.

In cases where you’re analyzing an already manufactured structure, assigning the correct material properties in the model is crucial to accurately reflect the real structure’s behavior. Sometimes, material strength tests on physical samples may be required to ensure accurate representation.

Assigning Materials in FEA: SDC Verifier

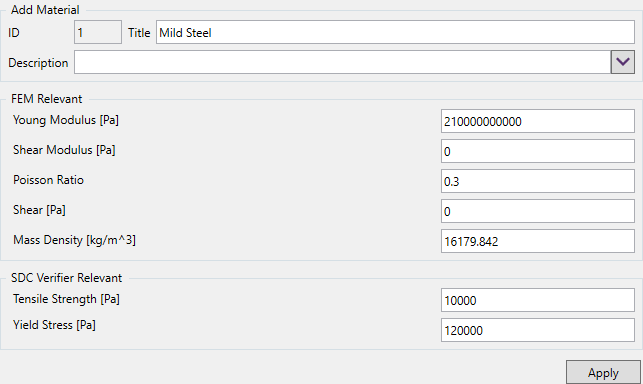

Structural analysis software like SDC Verifier supports isotropic and orthotropic (anisotropic) materials, especially when integrated with FEA solvers like Ansys or Simcenter. Material properties include FEM-relevant data imported from the model—such as Young’s modulus and Poisson’s ratio—and additional properties required for verification according to engineering standards, like allowable stresses, safety factors, and fatigue limits..

Material Management

Materials can be managed using the following options:

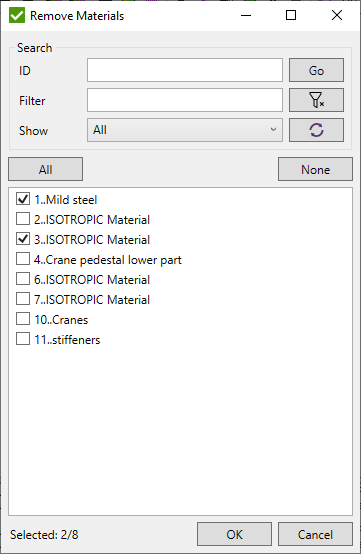

- Removing materials: Unused materials can be removed by navigating to Model – Materials – Remove Multiple, selecting the materials, and confirming removal.

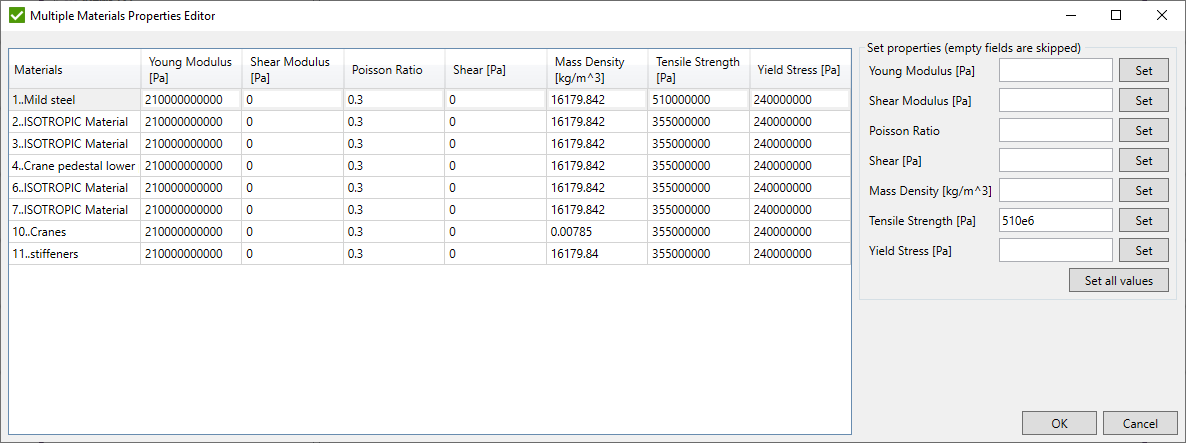

- Multiple editing: Batch-editing materials is possible using Model – Materials – Edit Multiple, allowing users to set corresponding or all values for selected materials.

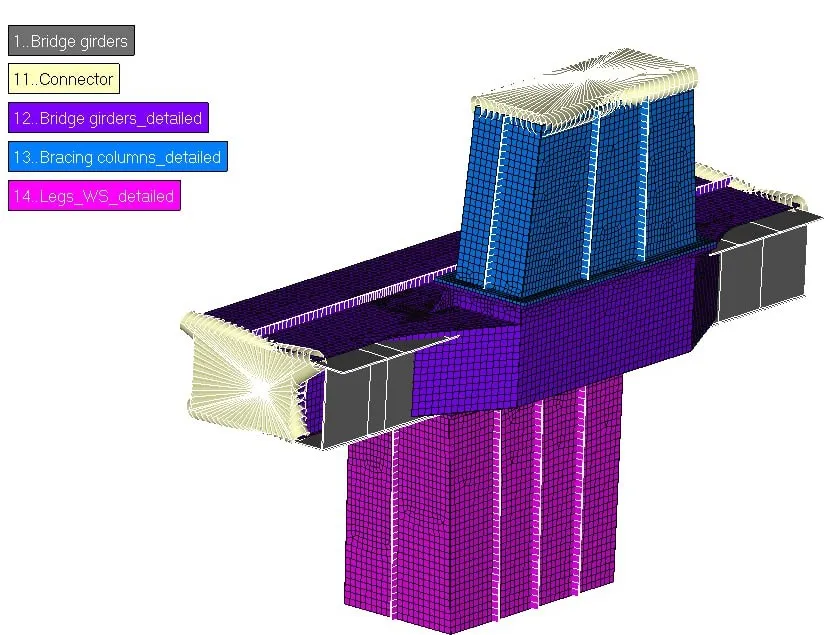

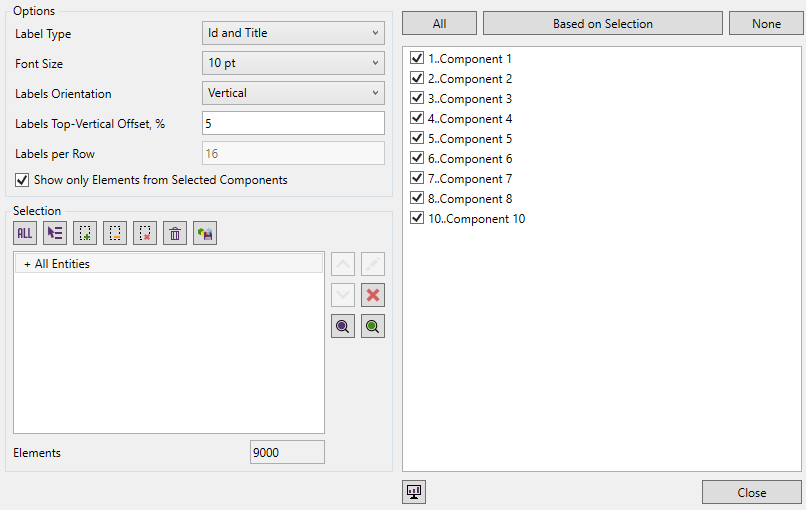

- Colored Plot: The Model – Materials – Colored Plot function visualizes assigned materials using distinct colors and labels.

Special Considerations for SDC Verifier Extensions

- SDC for Ansys: FEM-relevant data cannot be modified. Tensile strength and yield stress values edited in SDC Verifier will not affect Ansys material properties. The Update from Ansys option allows automatic updating of tensile and yield values from Ansys.

- SDC for Femap & Simcenter 3D: Materials are assigned and managed using similar tools, including multiple editing, material removal, and colored plotting for visualization.

For users working outside of commercial environments, FEA tools like Ansys Student Edition, FreeCAD, or SimScale offer accessible entry points for educational and preliminary analysis workflows.

Final Steps in Managing Materials in FEA

Once materials are assigned and managed within SDC Verifier, it is crucial to ensure consistency and accuracy before running structural verification. The final steps include:

- Ensure Compliance with Engineering Standards

- SDC Verifier allows you to incorporate material properties required by industry standards such as Eurocode, AISC, DNV, ASME, and others. While the software facilitates verification, it requires users to input the appropriate values based on the specific code requirements.

- The software uses yield stress and tensile strength values in compliance checks, but these values typically need to be input or confirmed by the user, especially if they aren’t imported from the native model.

- Optimize Material Selection for Verification

- Remove any unused materials from the model to make it cleaner.

- Use batch-editing to apply necessary modifications across multiple materials simultaneously.

- Run Structural Verification

- Once material assignments are confirmed, proceed with standard verification checks in SDC Verifier to ensure the model meets safety and regulatory requirements.

Conclusion

Accurate material assignment and management are essential for reliable finite element analysis and structural verification. With SDC Verifier, users can efficiently handle material properties, ensuring compliance with engineering standards while minimizing manual validation efforts.

The software simplifies the process through automated material updates, batch editing, and visual verification tools, reducing the risk of errors and improving overall analysis efficiency. By following best practices in material selection and assignment, engineers can enhance the accuracy of their simulations and achieve more reliable verification results.