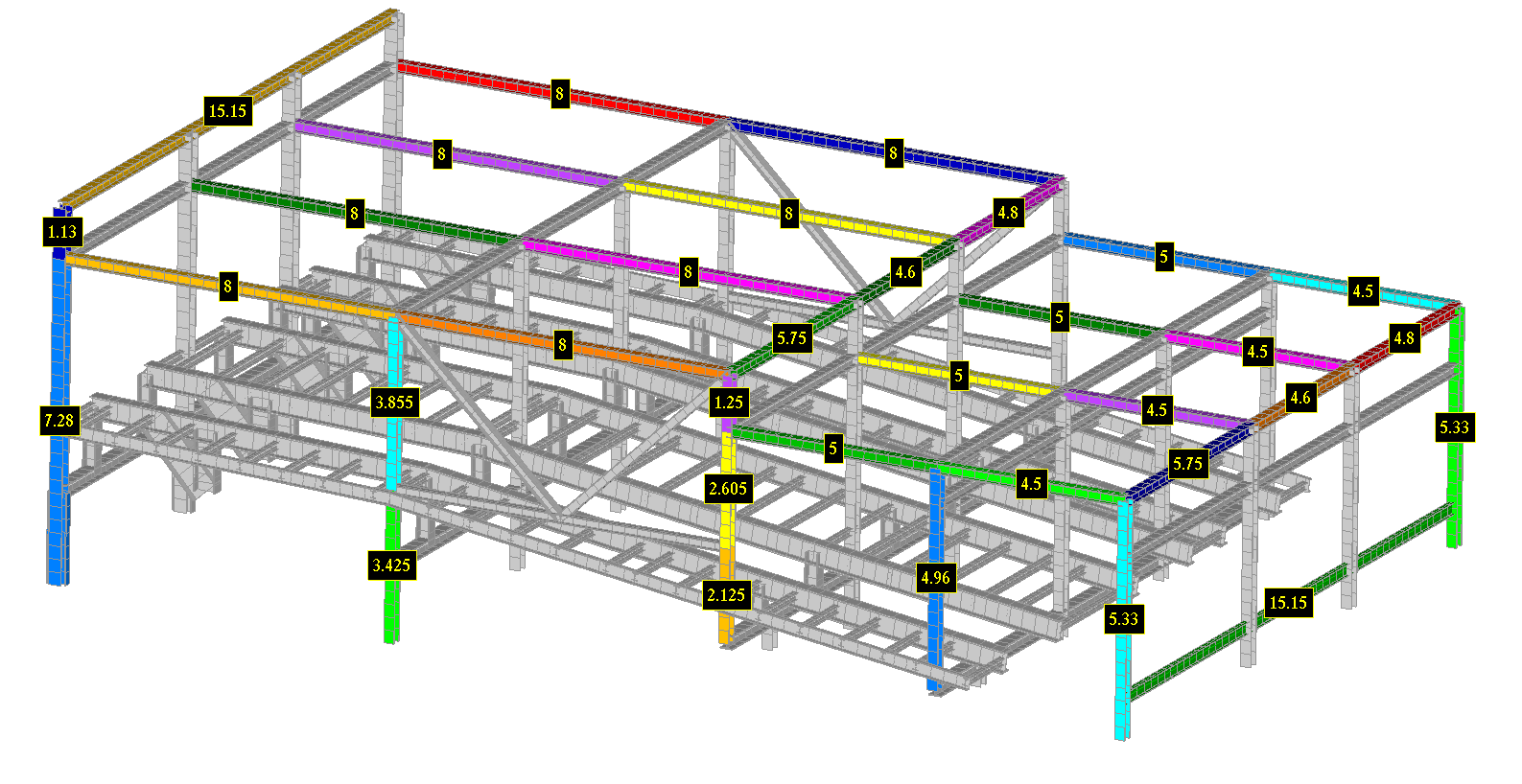

Recognition tools are used for automatic detection of different structural elements (joints, connections, beams, plates, welds) and further use them in checks according to industry rules and regulations or custom checks.

Construction safety is a crucial requirement for engineers’ tasks. To avoid collapse, each construction must be verified according to global and local industry standards. Performing checking according to standards is quite a complicated procedure. Besides the massive amount of rules to calculate (which depend on different shapes, materials, and other criteria), additional structure characteristics should be defined:

- For Beam Buckling – beam buckling length;

- For Plate Buckling – plate width, length, and direction;

- For Fatigue – welds classifications.

Manual defining these characteristics is possible only for small models, but still is time-consuming. For big models like vessels, it is impossible, for example, in ship models where 100-200 thousand plates are checked using specific standard.

We believe that characteristics detection routines can be automated. For that purpose, SDC Verifier implements a set of Recognition Tools.

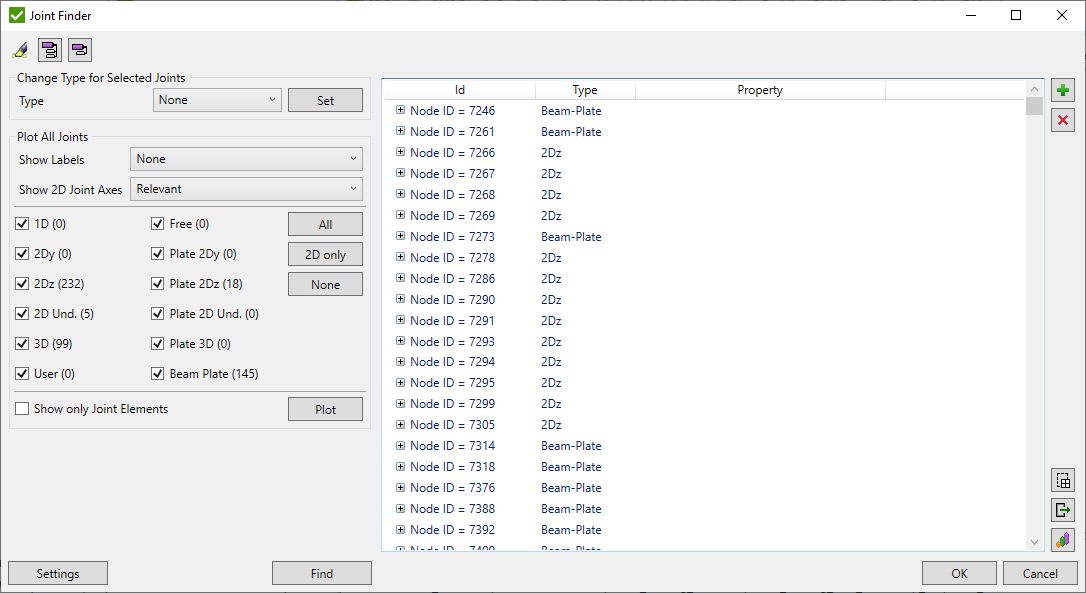

Joints Finder

Joints Finder is a powerful tool that helps to find and automatically detect different types of joints (1D, 2DY, 2DZ, 3D, etc.) that are used to find beam member lengths and connections for Joint Check. It is used by Beam Member Finder tool to recognize beam member length in 2 directions and by Joint Checks.

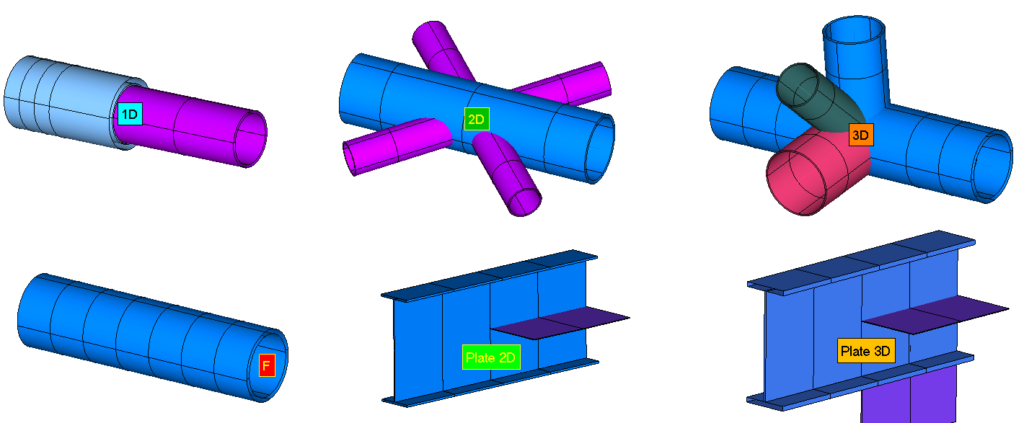

There following types of Joints are recognized automatically:

- 1D Joints – connection of 2 beam properties that lies on a straight curve. Can be used when setting up weld classification;

- 2D Joints – recognize 2D Y and 2D Z joints and Undefined (limit length in 1 direction);

- 3D Joints – limit length in both directions;

- Plate 2D, 3D, Undefined – both ends of a beam are fixed by a plate. The effective length factor = 0.01 is applied to reduce length;

- Beam-Plate Joints – a beam that is connected to a plate and is parallel to a plate normal vector with a tolerance = TOLERANCE ANGLE defined in Settings;

- User Joints – the joints defined by a user;

- Free Joints – the node which is connected only to one element.

The Joints Finder detects joint nodes between 1D mesh that are further used in Beam Member Finder, Connection Finder, and Joint Checks.

You have three options to automatically detect all joints:

- Remove All – removes all existing joints and performs joint detection from scratch;

- Keep only Modified (default) – joints that were modified by user are kept, the rest are removed and tools perform automatic detection of other joints;

- Keep all Existing – all existing joints are kept, Joint Finder will look for new joints;

Joints Finder is helpful for structure verification according to API RP 2A-LRFD, API RP 2A-WSD, ISO 19902, Norsok N004 standards

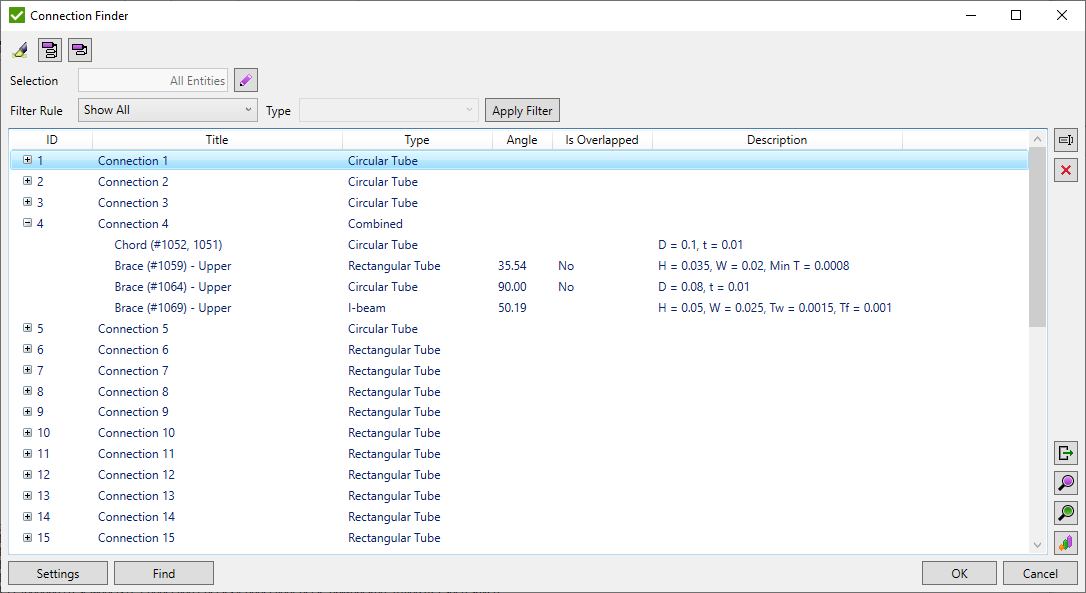

Connection Finder

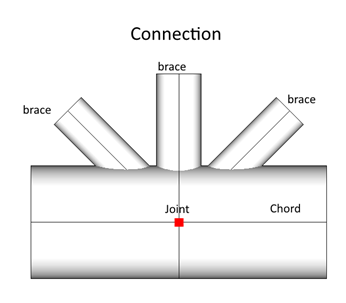

Connection Finder automatically detects connections and their dimensions in FEA model. Connection Finder based on Joints Finder.

Each connection is a set of elements connected to the joint node and consists of Chord (non-welded elements that form a straight line) and Braces (welded to chord elements at the joint node).

Connection Finder detects the following type of connections:

- Circular Tube Connection

- I-Beam Connection

- Rectangular Tube Connection

- Combined Connection (mix of previous connection types)

Multiplane connections are split into plane connections. Results of the Connection Finder Tool can be filtered by connection types or display connections where at least one of the braces overlaps another one.

Results of Connection Finder Tools used in SDC Verifier Eurocode 3. Connections (EN 1993-1-8, 2005) Check

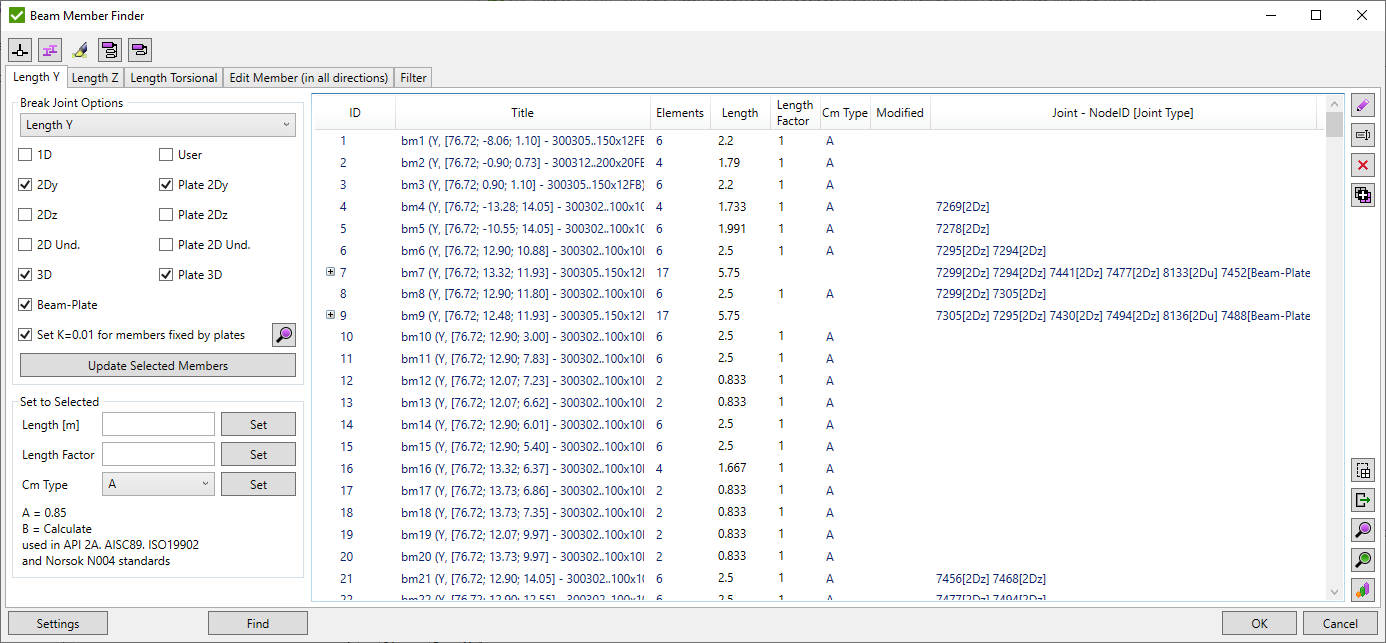

Beam Member Finder

Beam Member Finder detects beam members’ length in Y, Z, and Torsional directions based on Joints. Buckling length is calculated between the joints and does not depend on the model mesh.

If Beam Member contains joints, it is split on sub members. Break Joint Options define which types of joints will be used to split Beam Member on sub members. Engineer can manually modify beam member, turn off splitting joints and edit beam member (sub-member) length

It is possible to filter the members using the selection, the length criteria or display beam members that have different orientations.

Results of Beam Member Finder Tool can be used in AIJ-2017, AISC ASD 1989 Members, AISC 360-10 Members, API RP 2A-LRFD, API RP 2A-WSD, AS 3990, Eurocode 3. Members (EN1993-1-1), Eurocode 3. Fire Design (EN 1993-1-2), ISO 19902, Norsok N004 Checks.

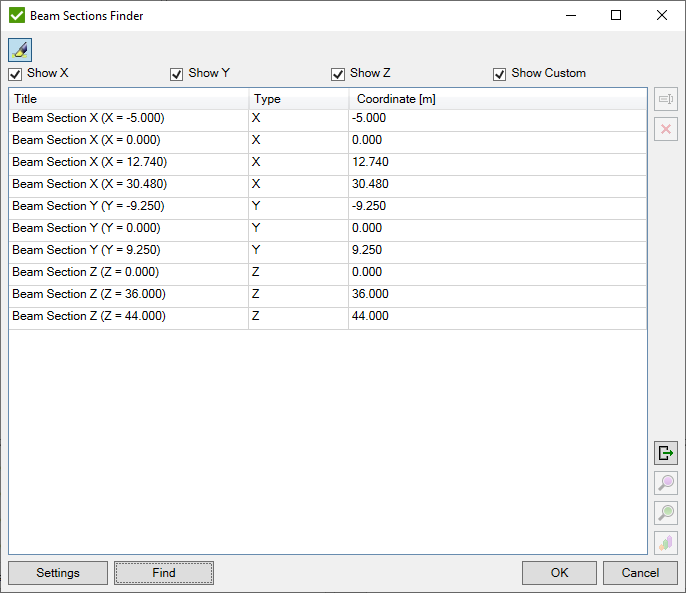

Beam Section Finder

Beam Section Finder helps to group line elements (1D) by planes. It is very similar to Panel Finder, but sections are recognized as beams/bars instead of plates. It is used to improve user experience in the selection process with selectors.

Panel Finder

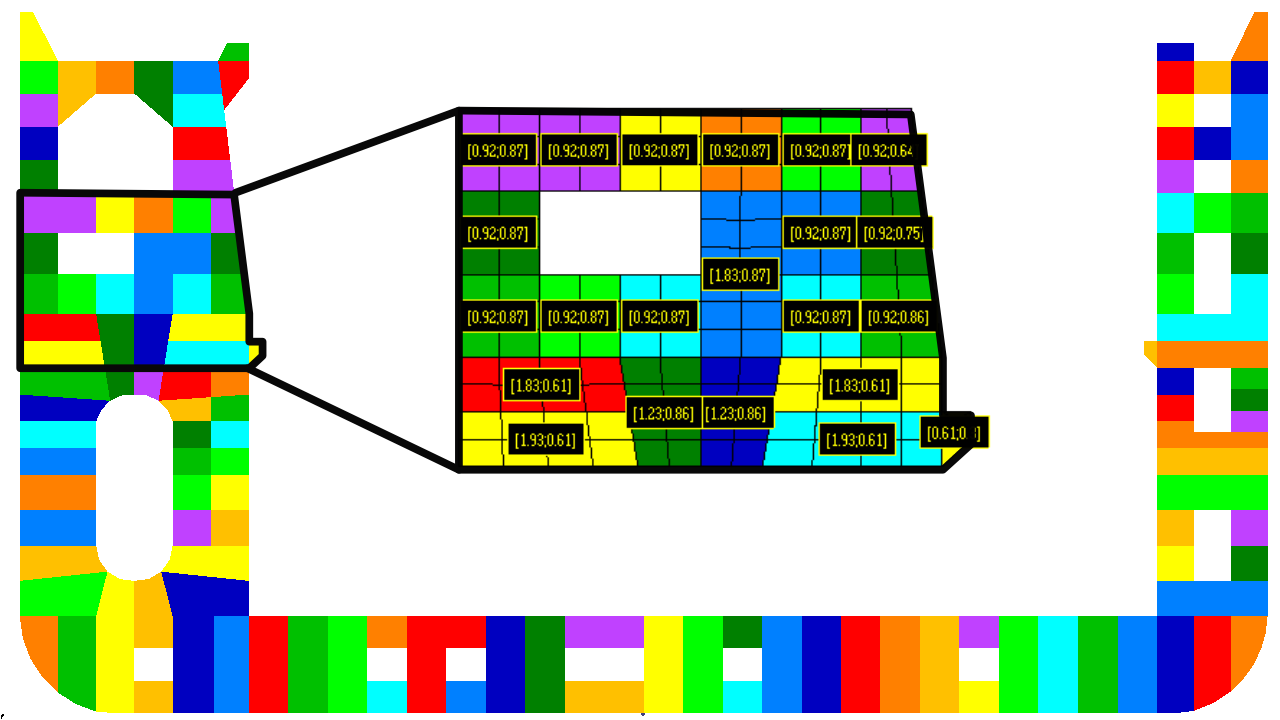

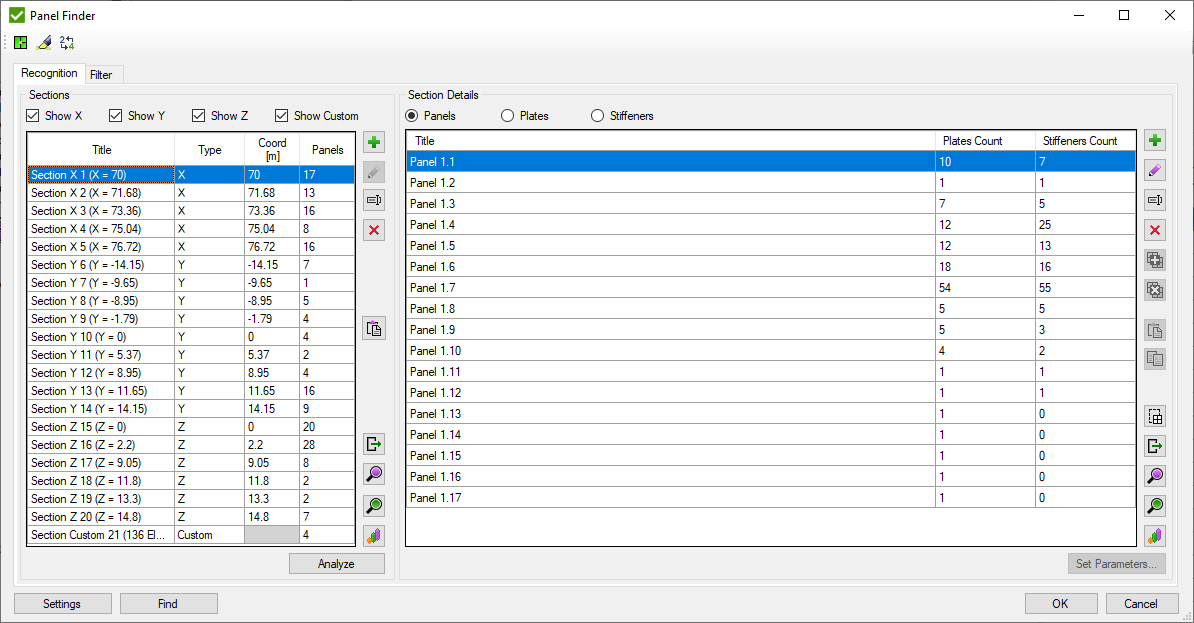

Plate buckling checks calculations are based on plate dimensions from the Panel Finder tool. Panel Finder automatically detects sections, plates, and stiffeners with the dimensions (length, width, thickness, and orientation) used in plate buckling calculations. According to standard stresses, plate direction should be checked (which is automatically translated by buckling check). Colored plots with labels (dimensions) make it easy to preview tool results:

After automatic recognition (detection) of plates there is an option to plot it along x, y, z axis or some curved or incline plates.

Plates are sets of elements which are surrounded by stiffeners or girders. It is possible to manually add delete or modify (change the length or width of the plate for cases when the recognition is not done properly because of some stiffeners or girders are missing) the plates.

Results of Panel Finder can be used in DNV CN30 Plate Buckling, DNV RP-C201 Plate/Stiffener Buckling, ABS Plate Buckling, and Eurocode 3.Plate Buckling (EN 1993-1-5) Checks.

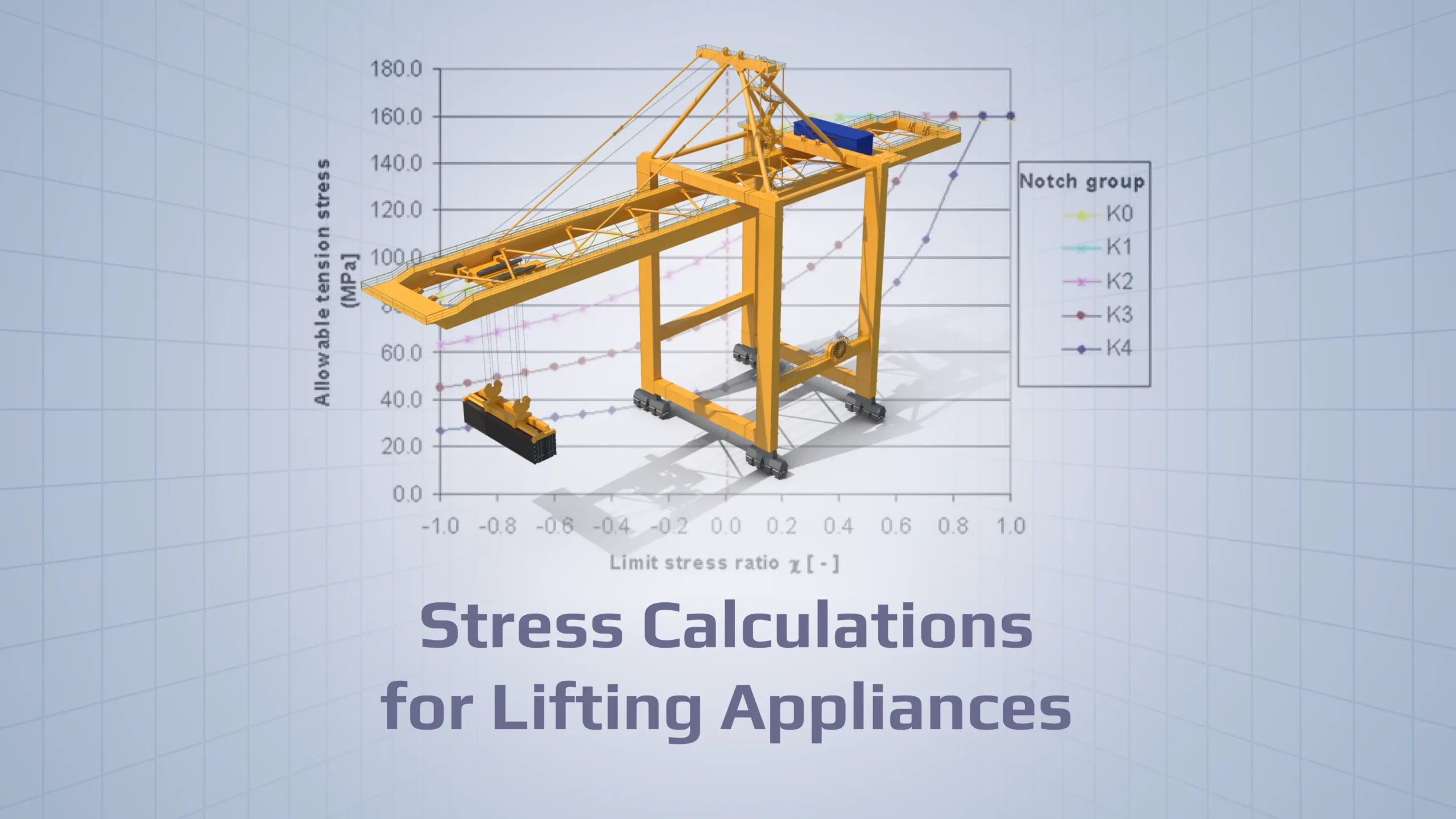

Weld Finder

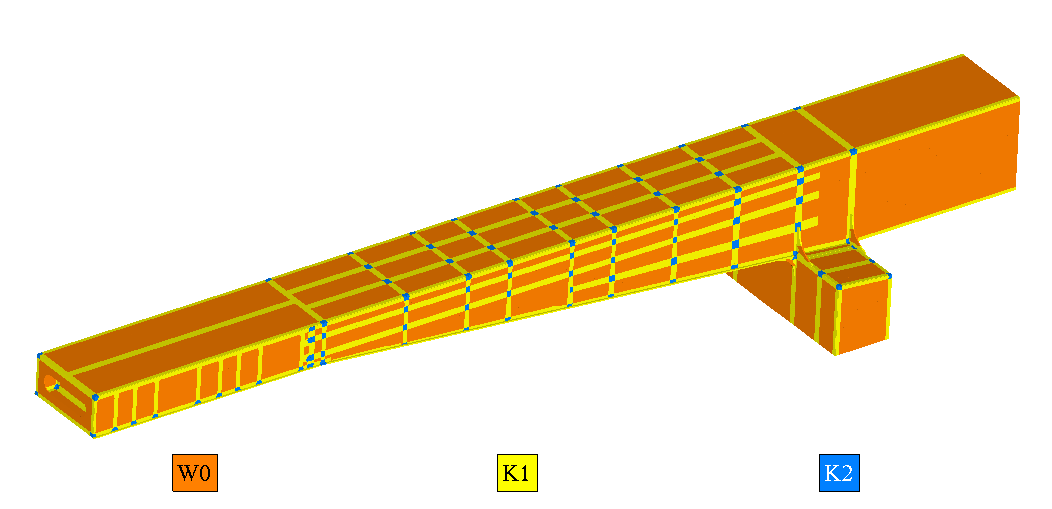

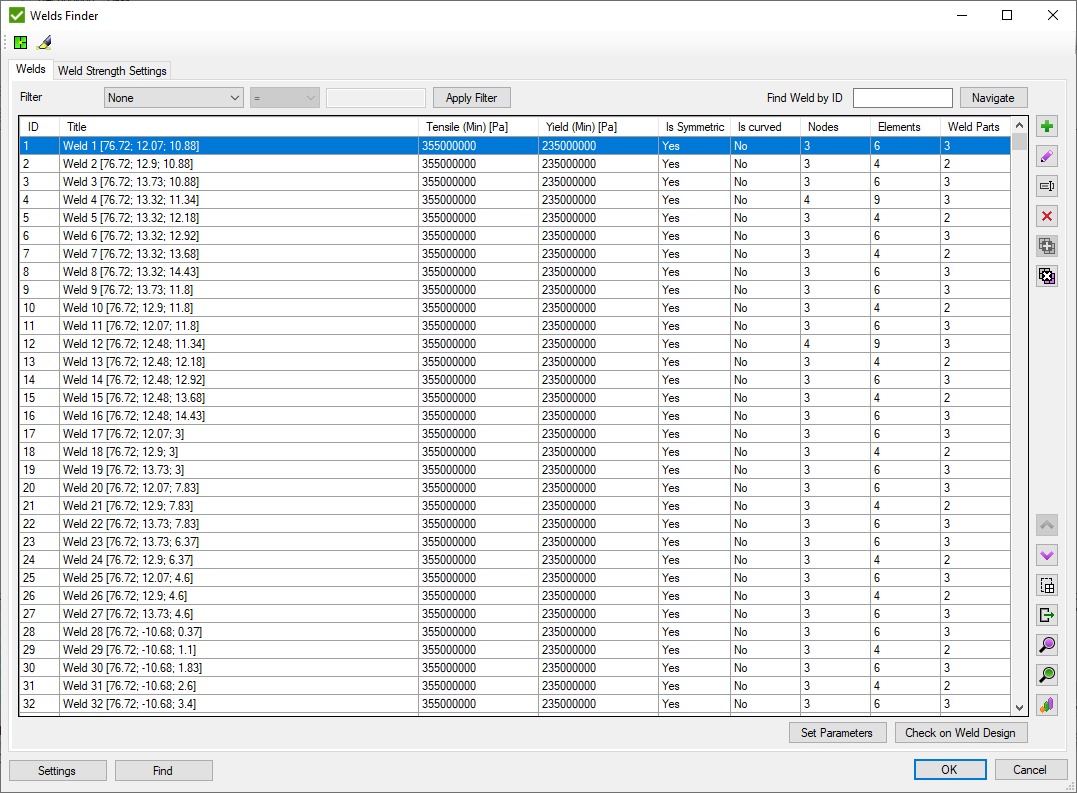

To perform a Fatigue Check, it is necessary to define Weld Type. It influences Allowable Fatigue Stress.

With the Weld Finder, it becomes straightforward to set the different weld types for the locations without weld, with weld (perpendicular K2 and parallel K1 to the weld), and for the intersections K2 in all directions. Weld Finder detects welds and automatically transforms the stresses from the elements’ local coordinate system into the weld direction for further use in fatigue and weld strength calculations.

Weld Stresses implemented as a separate category of result. All the tables/plots for stresses also can be created for the weld stresses. Conversion of stresses is performed automatically without reorientation of elements. So no rerun of the analysis is needed. It is possible to use the weld stresses for the checks by using the Sweld variable in the formula editor.

Results of Weld Finder Tool can be used in DIN 15018, DVS 1608, DVS 1612, DNV-RP-C203 Fatigue, DNV OS-C101-LRFD Weld Strength, DNV OS-C201-WSD Weld Strength, EN 13001, Eurocode 3. Weld Strength (EN1993-1-8), Eurocode 3. Fatigue (EN 1993-1-9), FEM 1.001, FKM (5th and 6th editions) Checks..