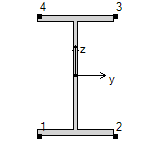

Example D.1 W-shape tension member

The results of tensile yielding and recommended slenderness limit calculation according to SDC Verifier and Design Examples of AISC (official version 14.1) are compared. The goal is to test SDC Verifier and reach valid results according to Specification for Structural Steel Buildings (ANSI/AISC 360-10 chapter D).

The results are generated with SDC Verifier 3.6 and calculated with FEMAP v11.0.0

Task:

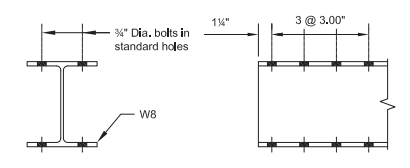

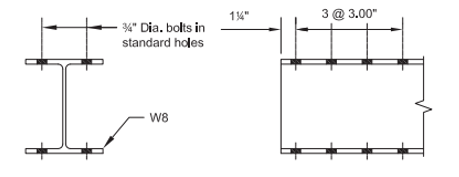

Select an 8-in. W-shape, ASTM A992, to carry a dead load of 30 kips and a live load of 90 kips in tension. The member is 25 ft long. Verify the member strength by both LRFD and ASD with the bolted end connection shown. Verify that the member satisfies the recommended slenderness limit. Assume that connection limit states do not govern.

Solution

From Chapter 2 of ASCE/SEI 7, the required strength is:

| LRFD | ASD |

|---|---|

| Pu=1.2(30kips)+1.6(90kips)=180 kips | Pa=30 kips+90 kips=120 kips |

From AISC Manual Table 5-1, try a W8×21.

From AISC Manual Table 4-2, the material properties are as follows:

- W8×21

- ASTM A992

- Fy=50 ksi

- Fu=65 ksi

From AISC Manual Table 1-1 and 1-8, the geometric properties are as follows:

- W8×21

- Ag =6.16 in.2

- bƒ =5.27 in.

- tƒ =0.400 in.

- ry =1.26 in.

- WT4×10.5

- γ‾ =0.831 in.

- Tensile Yielding

From AISC Manual Table 5-1. the tensile yielding strength is:

| LRFD | ASD |

|---|---|

| 277 kips > 180 kips o.k | 184 kips > 120 kips o.k |

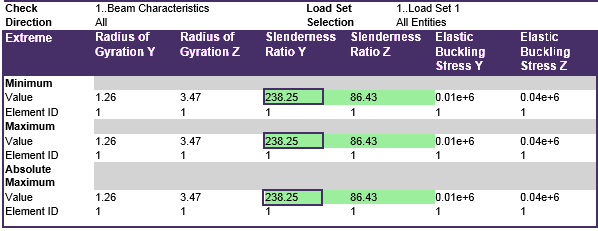

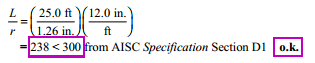

Check Recommended Slenderness Limit.

=238 < 300 from AISC Specification Section D1 o.k.

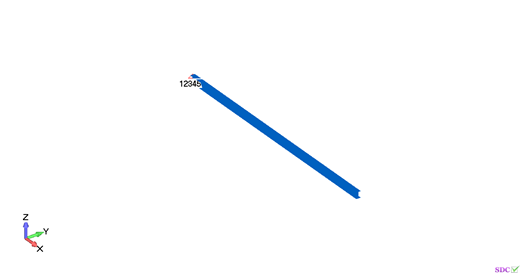

All units of measurement were chosen according to British metric system (lb, in, lb/in^3, lb/in^2).

Material used is A992 Steel with Yield Stress = 50000 and Tensile Strength = 65000.

Area section W8×21 is modified manually from original area 6.06 to 6.16, because section is modeled without fillets.

| Geometry Property | Value |

|---|---|

| Height | 8.28 |

| Width | 5.27 |

| h | 8.28 |

| a | 5.27 |

| b | 5.27 |

| c | 0.40 |

| d | 0.25 |

| t | 0.40 |

Example from AISC Design Examples

| W8×21 | |

| Ag =6.16 in.2 | |

| W8×21 | bƒ =5.27 in. |

| ASTM A992 | tƒ =0.400 in. |

| Fy= 50 ksi | d =8.28 in. |

| Fu =65 ksi | ry =1.26 in. |

Note: I-beam was created in Femap (built-in section) with area A =6.06 m^2 (fillets of rolled section weren’t taken into account), but in SDC Verifier area was changed to A = 6.16 m^2 according to the input data of the example.

FEM Loads and Constraint

2..Dead load 30 kips

| Definition Title | Load Type | Applied on | Value(s) |

|---|---|---|---|

| 1..Force on Node | Force | Node: 11 | (30000;0;0) |

3..Live load 90 kips

| Definition Title | Load Type | Applied on | Value(s) |

|---|---|---|---|

| 1..Force on Node | Force | Node: 11 | (90000;0;0) |

1.Fixed

| Definition | Count | Type (DOF) |

|---|---|---|

| 1..Constraint on Node | 1 node(s) | Tx Ty Tz Rx Ry Rz |

Check 1..ANSI / AISC LRFD 360-10

Slenderness check

Check Recommended Slenderness Limit

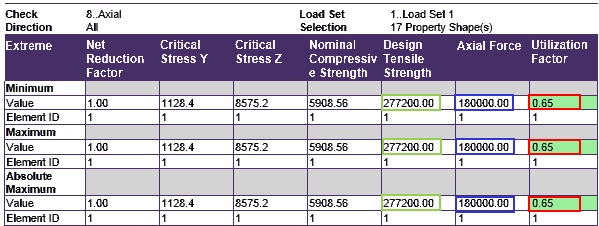

Axial Check

All (LS1, 17 Property Shape(s))

From Chapter 2 of ASCE/SEI 7, the required tensile strength is:

Tensile Yielding

From AISC Manual Table 1-5, the tensile yielding strength is:

Comparing results of calculation in SDC Verifier and in Example D.1 it can be seen that the values completely match. Tensile yielding stress is 277 kips > required tensile stress is 180 kips. Slenderness ratio Y is 238 < maximum slenderness limit for members in tension is 300 (AISC 360-10 chapter D.1).

Download SDC Verifier project file, model and report Example D.1

Full list of AISC 360-10 Examples