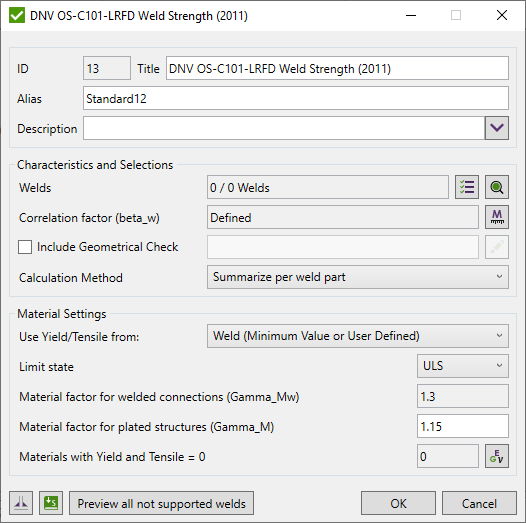

DNV OS-C101-LRFD Weld Strength (2011)

An offshore standard DNV OS-C101-LRFD Weld Strength (2011) verifies structural stability for each structural member (weld). Weld connections (section 9) is implemented.

To add the standard execute from the ribbon:

Common options are described in the Weld Strength Settings chapter.

Press  to Set Standard Custom Settings

to Set Standard Custom Settings

Press  to set a Correlation factor (Beta_w):

to set a Correlation factor (Beta_w):

![]()

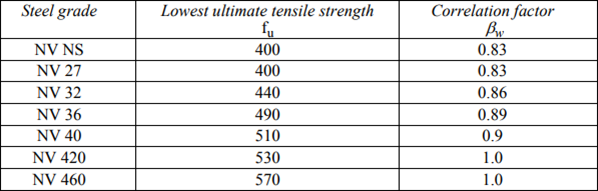

factor is obtained from Table C4, section 9 and depends on the material type:

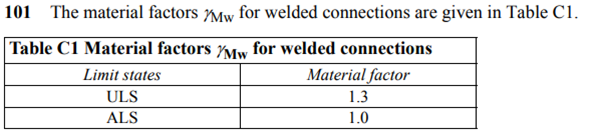

- material factor that is used for DNV OS C 101 calculations can be found in Table C1, section 9 of the standard:

- material resistance factor for plated structures is a constant value (=1.15) and used in calculations to check base material strength.

Standard uses material data (Yield/Tensile) in calculations. Wizard checks if the values are defined for all materials.

Checks are created automatically and divided into few parts:

- Dimensions checks. Geometrical parameters weld area, elastic section modulus etc;

- Stress checks. Total weld throat stresses at the start and at the end of the weld. Weld Stresses are calculated using the weld dimensions at four points at the weld ends;

- Utilization factors. Total utilization factors, base material check and overall utilization factor checks.

Permissible stresses for welds are calculated as described in a standard (using the Tensile Strength) and compared to the Von Mises stress. These are formulas of Check 13.

Permissible stress for the material is calculated using the yield of the material (Check 14). But then the Von Mises stress is calculated assuming weld angle is 0° (even for fillets where angle = 45°) and resistance using weld throat = weld leg length (z). In this case the stresses are calculated not in the weld face, but in weld coordinate system.