Eurocode3 Plate Buckling (EN 1993-1-5, 2006)

Eurocode3 Plate Buckling (EN 1993-1-5, 2006) gives design requirements of stiffened and unstiffened plates which are subject to in-plane forces. Chapter 10 is implemented.

To add the Standard execute from the ribbon:

Plate and Stiffener Buckling Checks are calculated on Sections. With the help of Panel Finder tool, it is possible to automatically recognize Section and Plates with their dimensions.

By default, All Sections are included in the selection but it can be changed by pressing  .

If sections were not recognized press

.

If sections were not recognized press  to run Panel Finder tool.

to run Panel Finder tool.

Press  to Set Standard Custom Settings

to Set Standard Custom Settings

Standard uses material data (Yield/Tensile) in calculations. Wizard checks if the values are defined for all materials.

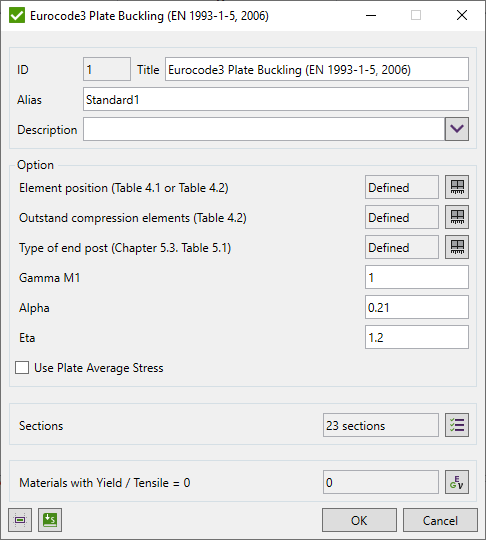

Options

Element position (Table 4.1 or Table 4.2) - used for buckling factor calculations. Table 4.1 or Table 4.2;

Outstand compression elements - different cases of stress distribution according to Table 4.2;

Type of end post - Chapter 5.3. Table 5.1;

Gamma M1 - resistance of members to instability assessed by member checks. Recommended value by National Annex = 1.00;

Alpha - used in calculations of χc factor in Chapter 6.3.1.2 of EN 1993-1-1 standard. Chapter 4.5.3 (5);

Eta - used in Table 5.1. The value = 1.20 is recommended by National Annex for steel grades up to and including S460. For higher steel grades value = 1.00 is recommended;

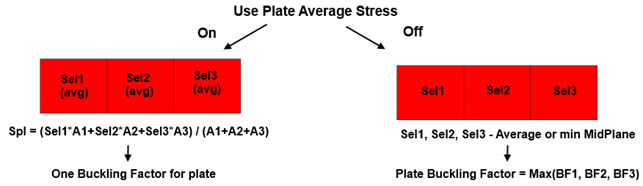

Use Plate Average Stress - use average element stress if OFF or averaged stress on the plate using elements area if ON;

Stress Conversion

Plate Buckling check requires to verify element stresses (Sx, Sy and Txy) to be translated into the plate X, Y, XY directions.

Conversion of the stresses is done automatically in Plate Buckling check. If Use Plate Average Stress option is turned OFF (by meaning element average option is used) - the nodal element stresses at top and bottom are averaged (which is equivalent to using midplane centroid stress) and translated into plate directions.

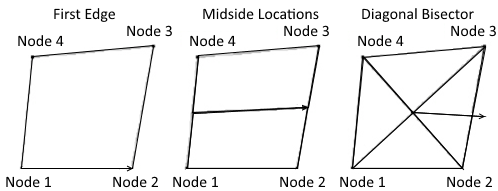

SDC Verifier makes an assumption that the plate elements are calculated without any output transformation and the default values are used:

- For triangle elements x stress is oriented along the first ege (node1 -> node2 define 1 edge).

- For quad elements x stress is oriented along the Diagonal Bisector:

Plate Dimensions and Thickness

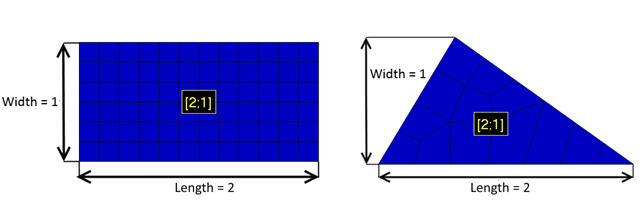

Results depend on the plate dimensions and direction. It is important to understand how the Panel Finder performs recognition. Length is considered to be the longest edge of the plate and width the longest perpendicular to the longest edge:

Plate dimentions can be calculated using CSR method - calculate equivalent rectangular plate dimensions described in Common Structural Rules (1 Jan 2018) Part 1, Chapter 8, Section 4 (2.3)

Calculations are performed on every element and thickness is taken directly from each element. It is possible to set thickness manually, in this case, element thickness will be ignored and user-defined thickness will be used.

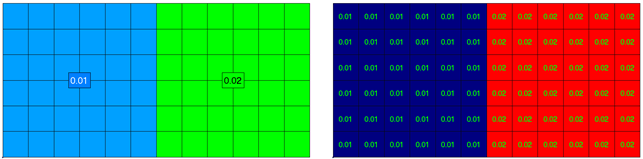

Example: A Plate with 2 properties 0.01 and 0.02 thicknesses. The left picture displays the property labels with property thicknesses and the right one presents plate buckling plot of thickness parameter: