What Are Structural Properties in Finite Element Analysis (FEA)?

Structural properties in FEA are fundamental to understanding how materials and structures behave under various conditions. The accuracy of FEA simulations heavily depends on the precise definition of structural properties, which include material characteristics and geometric attributes. This article delves into the importance of these properties, their role in FEA, and how they impact the accuracy of models.

Understanding Structural Properties in FEA

Structural properties define how elements behave mechanically within a finite element model, affecting stiffness, mass, and stress distribution. These properties encompass:

Material Properties

- Elastic Modulus (Young’s Modulus): Measures the stiffness of a material. Higher values indicate stiffer materials.

- Shear Modulus: Represents a material’s response to shear stress. It’s essential for analyzing deformation under torsional or shear loading.

- Poisson’s Ratio: Describes the ratio of transverse strain to axial strain. It is crucial for understanding how materials deform under stress.

- Density: Influences the mass and inertia of the structure, affecting dynamic analysis.

- Thermal Conductivity: Important for thermal analysis, determining how heat flows through materials.

- Yield Stress: Indicates the stress level at which a material begins to deform plastically. It’s key to determining the elastic limit.

- Tensile Strength: The maximum stress a material can withstand while being stretched before breaking. It defines the upper limit of the stress-strain relationship.

Geometric Properties

- Thickness: In shell and plate elements, thickness is a critical parameter that affects bending and stress distribution.

- Cross-section: The geometry of the cross-section is used to calculate properties like the cross-sectional area and moment of inertia, which influence the strength and stiffness of beam elements.

- Moment of Inertia: Affects the bending resistance of beams and other structural elements.

Role of Structural Properties in FEA

Structural properties play a pivotal role in FEA by defining how each element behaves under various conditions. Accurate material and geometric properties ensure that the simulation results closely mimic real-world behavior. Here are some key roles these properties play:

- Stress-Strain Relationship:

The stress-strain curve of a material, defined by its elastic modulus and yield strength, determines how it will deform under load. Accurate stress-strain data is essential for predicting failure points and ensuring structural integrity.

How SDC Verifier Enhances Structural Property Management

SDC Verifier, structural design and analysis software, streamlines structural verification by using predefined material and geometric properties from the model to perform checks against industry standards. The Properties Menu in SDC Verifier allows:

- Add / Remove / Renumber Properties

- Color-code and visualize properties in the scene

- Assign materials to multiple properties

- Plot labels for plate thicknesses

- Add to Library for reuse of shaped (bar/beam) properties

- Entity visibility control for visual inspection of properties

By integrating SDC Verifier with leading FEA software like Ansys, Femap, and Simcenter, engineers can reduce manual errors and ensure compliance across all structural simulations.

Impact of Structural Properties on Model Accuracy

1. Predictive Capability

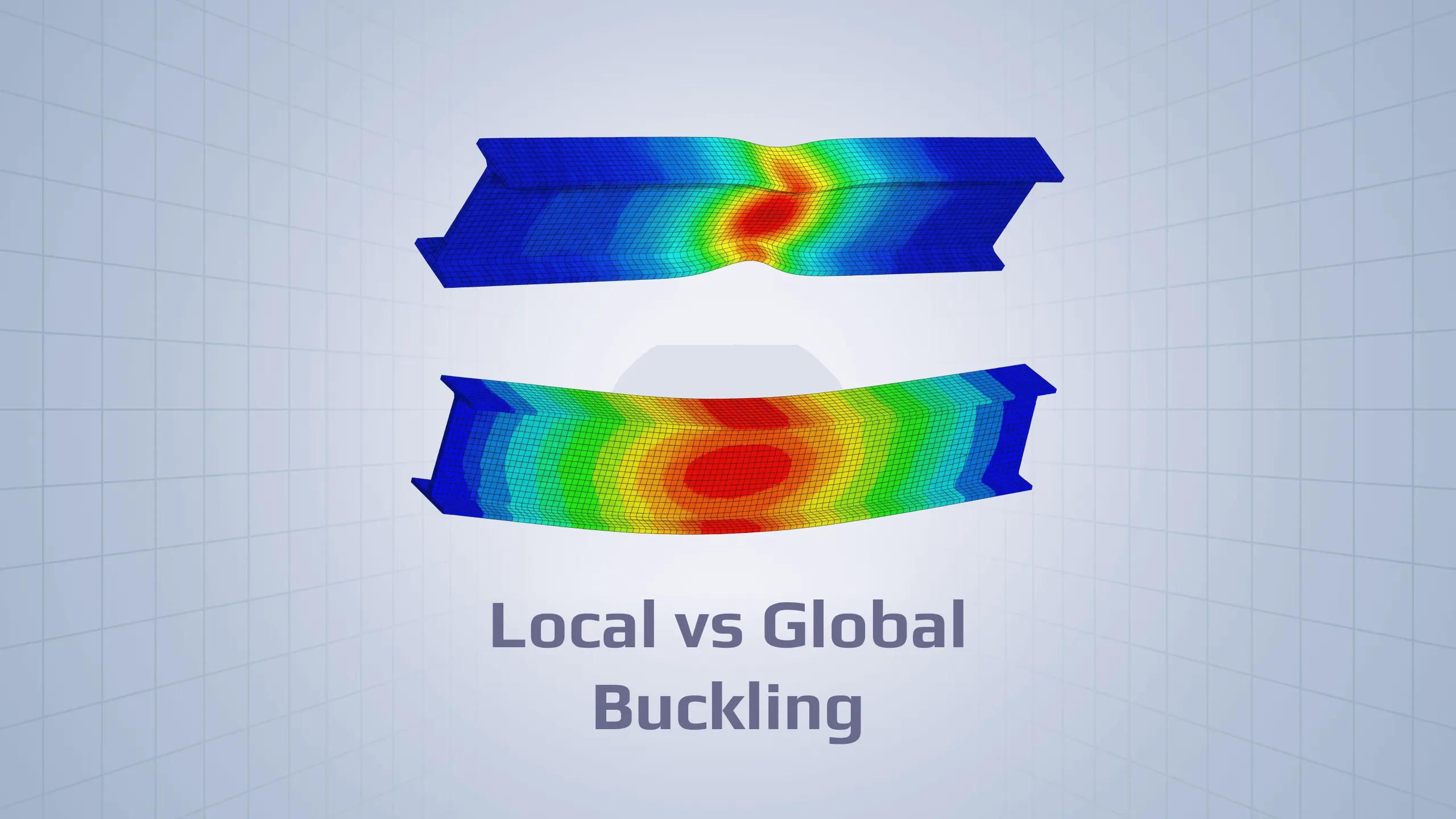

Accurate structural properties allow engineers to predict failure modes, deformation, buckling, fatigue life, and stress concentrations. Inadequate or overly simplified definitions may lead to under-design (unsafe) or over-design (inefficient).

2. Structural Stability

The structural properties directly influence the overall stability of the system. For instance, inadequate stiffness or improper design can lead to buckling, excessive deformations, or collapse under load. Ensuring the right balance of material and geometric properties is essential for a stable and safe structure.

3. Computational Efficiency

Overly detailed material models (e.g., rate-dependent or anisotropic behavior) increase computational time. Engineers must balance realism and efficiency by selecting the appropriate level of detail in structural properties based on simulation objectives.

Real-World Application Example: Offshore and Mechanical Structures

In high-stakes industries such as offshore, civil, and mechanical engineering, structural properties must comply with international standards (e.g., DNV, Eurocode, ASME, etc.). A steel beam used in a maritime structure must be modeled with standard-compliant properties including yield strength, fatigue parameters, and corrosion allowances.

SDC Verifier, a simulation and structural analysis software, enhances traditional FEA workflows by integrating automatic recognition and assignment of structural properties based on geometry and material libraries. It helps validate models against multiple standards without manually adjusting each property, ensuring both accuracy and compliance.

Best Practices for Defining Structural Properties

To ensure optimal accuracy in FEA, follow these best practices:

- For Linear Analysis: Use verified linear material properties such as elastic modulus and Poisson’s ratio. Simplify the model by assuming elastic behavior when plastic deformation or other non-linear effects are negligible.

- For Non-Linear Analysis: Incorporate detailed material behavior, including plasticity, large deformations, and damage models as needed. Use accurate stress-strain curves and account for effects like yield stress and hardening.

Conclusion

Structural Properties in FEA are the backbone of accurate and reliable simulation models. From basic attributes like Young’s modulus to more complex behaviors involving thermal or dynamic responses, these properties influence every step of the analysis process. Engineers must treat the definition of structural properties with the same rigor as geometry or meshing.

Whether you are modeling a steel bridge, a composite aircraft component, or a subsea pipeline, remember simulation accuracy begins with the right structural properties.

For engineers aiming to streamline this process and ensure compliance with international standards, tools like SDC Verifier offer a powerful extension to traditional FEA software — making verification easier, faster, and more accurate.