Understanding Plate Buckling in Offshore Structures: Analysis and Standards with SDC Verifier

Plate buckling strength is a critical factor in designing offshore steel structures, as it directly affects the stability and safety of the entire construction. Each plate must withstand buckling forces, especially in vital components like ship hulls, which are composed of multiple interconnected panels subject to complex loading conditions.

This article explores the fundamentals of plate buckling, key factors that influence it, and various types of buckling. Additionally, it reviews calculation methods and how SDC Verifier’s automated tools streamline the analysis process, ensuring compliance with industry standards and efficient design validation.

SDC Verifier implements plate buckling check in ANSYS, Femap or Simcenter 3D according to the following Standards:

- DNV CN30/1995 (Buckling Strength Analysis), DNV RP-C201 2010 (Buckling Strength of Plated Structures)

- American Bureau of Shipping (ABS) Steel Vessel Rules 2006, ABS 2014 (Buckling and Ultimate Strength Assessment for Offshore Structures)

What is Buckling?

Buckling in plates refers to a lateral instability that causes the plate to deform out of its plane under compressive stress, resulting in a wave-like or ‘wrinkling’ pattern across its surface.

This instability can escalate to structural failure, making thorough analysis essential — particularly in offshore and marine environments where plates face complex and variable load conditions. Addressing buckling risks in the design phase is critical to ensure the reliability and safety of the entire structure.

Causes of Plate Buckling

Plate buckling is primarily caused by compressive forces acting parallel to the plane of the plate. When a plate is loaded beyond its elastic stability limit, it reaches a critical stress point at which it can no longer maintain its original flat shape, leading to buckling. The main causes include:

- Axial Compression: The most common cause of plate buckling, where compressive forces act along the length of the plate, pushing it into an unstable state.

- In-Plane Shear Stresses: Plates under shear forces can also experience buckling, especially if they are thin and have a high aspect ratio. This type of stress is common in offshore platforms and other structures facing lateral forces from wind or waves.

- Out-of-Plane Pressure: Buckling can also occur due to differential pressure on the plate surface, such as water pressure on submerged plates or panels in underwater structures.

Types of Plate Buckling

There are several types of plate buckling, each influenced by different loading conditions, plate geometry, and boundary constraints. Understanding these types is essential in engineering as it dictates the analysis methods and preventive measures needed:

| Buckling Type | Description | Applications |

|---|---|---|

| Local Buckling | Occurs in small sections, such as individual panels within a larger structure, where parts buckle independently. | Common in stiffened panels (e.g., ship hulls) |

| Global Buckling | Involves the entire plate deforming as a single entity, posing a greater risk to overall structural integrity. | Large structural plates and panels |

| Distortional Buckling | A combination of local and global buckling where individual sections buckle, impacting the entire plate’s shape. | Thin-walled plates with complex shapes |

| Shear Buckling | Caused by lateral loads (e.g., wind or wave forces), leading to sideways distortion. | Offshore platforms, high-aspect-ratio plates |

Factors Influencing Plate Buckling

- Plate Geometry: The length-to-width (aspect ratio) and thickness greatly impact a plate’s buckling resistance. Higher aspect ratios increase susceptibility to buckling under compression.

- Material Properties: The material’s stiffness and yield strength directly affect buckling resistance. Steel is commonly used in offshore structures for its high resistance, but it requires precise calculations to avoid overloading.

- Edge Conditions: Plates with fixed edges provide greater resistance to buckling than those with free or simply supported edges. Boundary conditions should reflect real-world constraints to ensure accurate assessments.

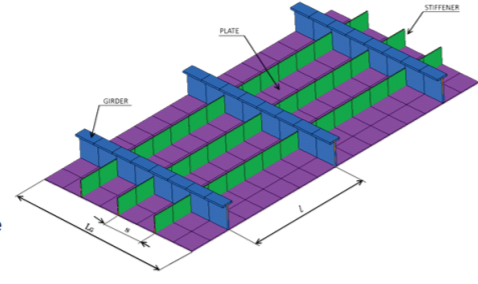

- Type of Stiffeners: Stiffeners enhance rigidity and reduce buckling risk. SDC Verifier’s Panel Finder automatically identifies and includes these reinforcements in buckling assessments.

Theoretic background of the plate buckling

SDC Verifier CEO Wouter van den Bos created educational video on buckling fundamentals:

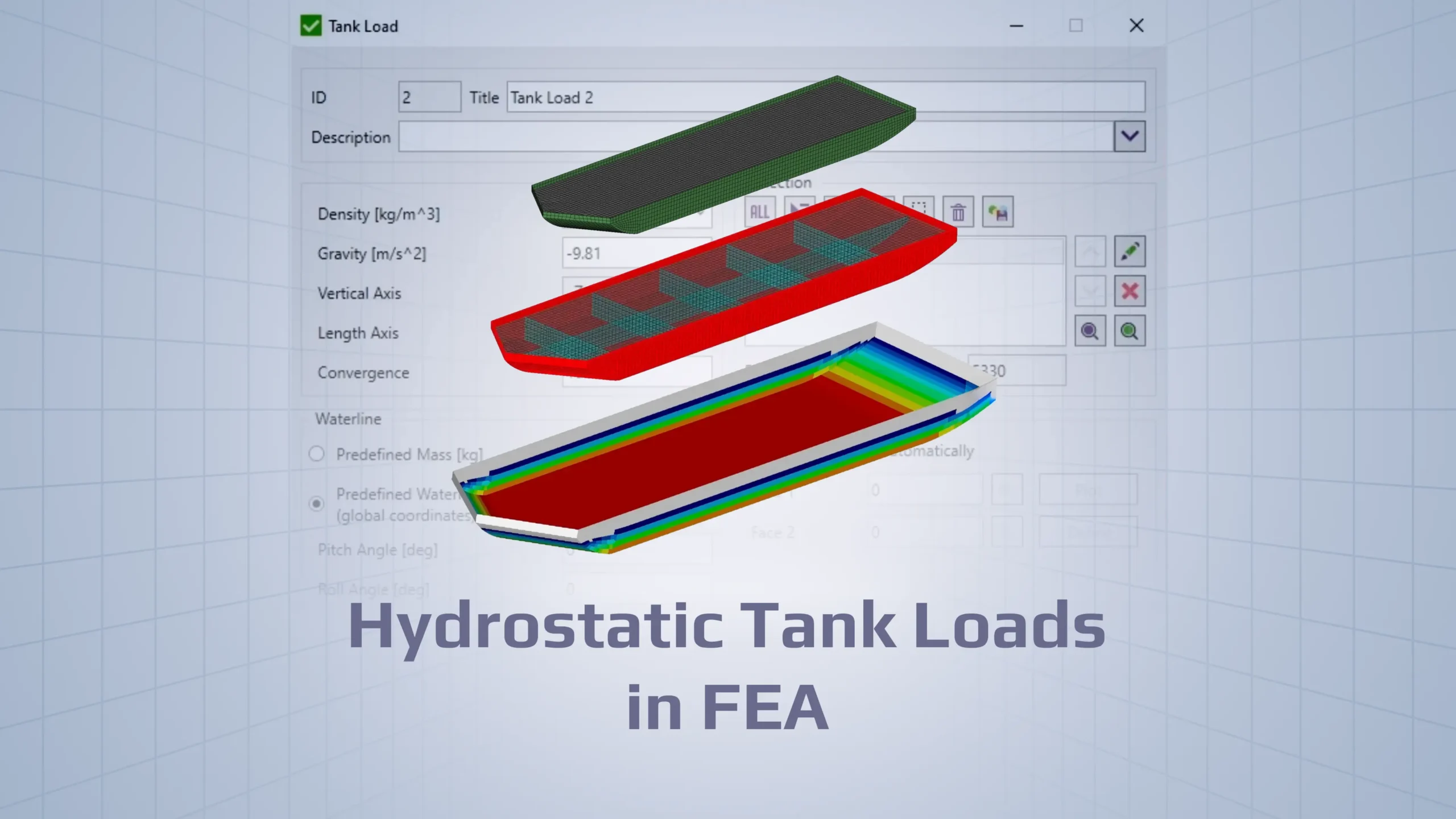

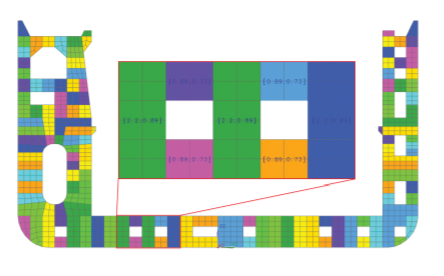

The most complicated task in performing plate buckling check on a general Finite Element Analysis model is to define a big amount of plates and dimensions of these plates to be verified.

Manual recognition of all the plates is a time-consuming operation, but we have an automatic model FEA recognition tools that can ease the process. SDC Verifier bring to user the Panel Finder — tool to automatically recognize sections, panels, plates, stiffeners and girders, and dimensions of these structural members.

The recognition of plates, stiffeners and girders is based on mesh connectivity and can be performed on any structure which is built with either plate or shell elements.

SDC Verifier recognizes automatically all the structural members, and mesh independently. This brings to user an opportunity to have a model with fine mesh for precise results of the general finite element analysis and use the same model for calculation ABS plate buckling or DNV plate buckling checks.

Plate Buckling calculation approach

Plate buckling check results are Ultimate Strength Limit and Buckling State Limit. These results depend on plate stresses and plate dimensions (length, width and thickness).

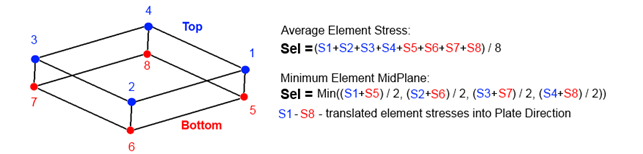

Various options for stresses checked:

- Element Stress: MidPlane (no bending) or Average;

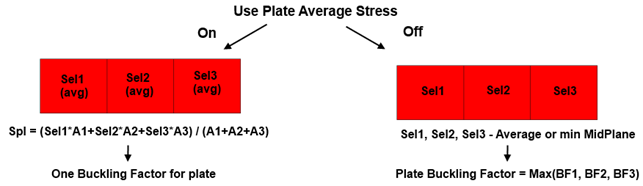

- Use Plate Average Stress – stress is averaged on plate using elements area. SDC Verifier performs calculation on every element but with averaged plate stresses.

For Plate Average Stress it’s also possible to use an Average Shear Stress or conservative method of taking Absolute Shear.

Note: Plate buckling checks require verifying stresses into the plate direction (direction of the longest plate edge). In SDC Verifier conversion of stresses is done automatically. For average option stresses are firstly averaged and then translated.

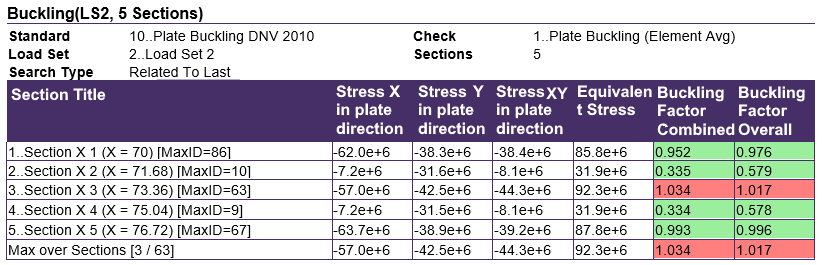

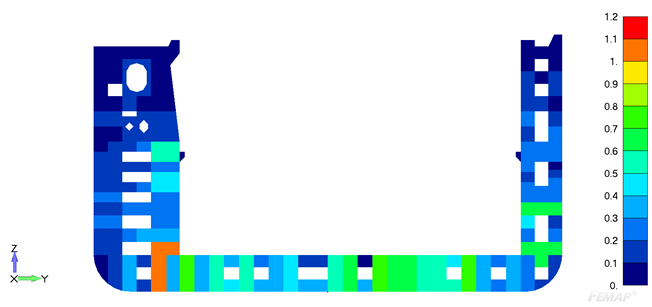

Results of buckling check in SDC Verifier

SDC Verifier presents buckling check results in a user-friendly format, providing:

- Tables: Display results across various load combinations or selections.

- Plots: Visualize buckling outcomes for any view or selection, offering engineers insights into potential instability points. These formats make it easy to interpret results and adjust designs as needed.

Plate Buckling Checks According to DNV 2010 (Buckling Strength of Plated Structures) Webinar

SDC Verifier provides a robust solution for plate buckling analysis, from automatic model recognition to comprehensive DNV and ABS compliance checks. To explore the software’s capabilities in detail, download SDC Verifier and enhance the structural integrity of your designs.