- Software

DOWNLOADSINDUSTRIESSTANDARDS

Verwater verified a 24 m storage-tank roof using SDC for Ansys

Read Full Story - Consultancy

SERVICES

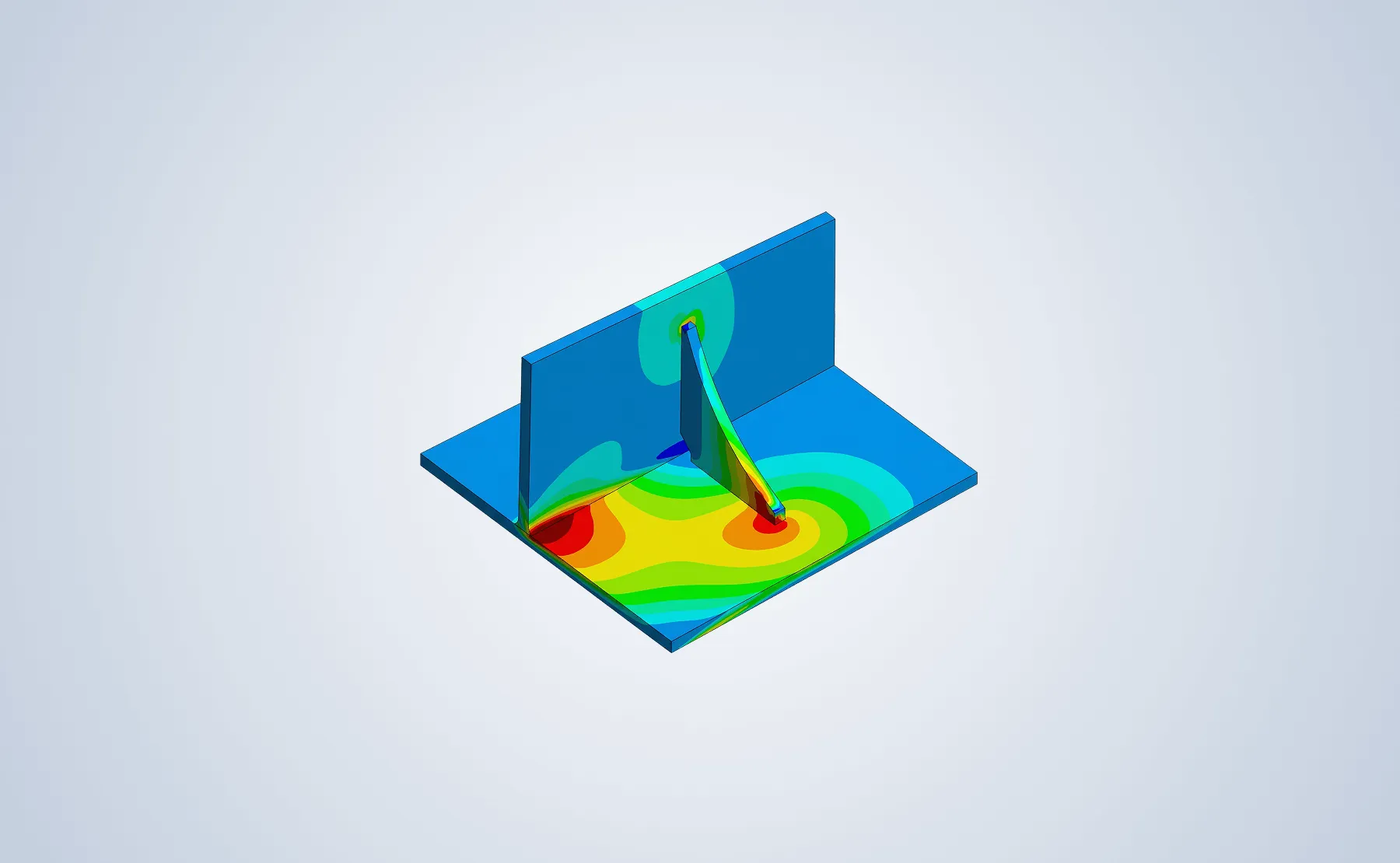

Analysis of the cylinder system of grab unloader

All Projects - Learning&Support

LEARN

AS 4100:2020 Fatigue in SDC Verifier – How Section 11 Is Implemented

Read Full Article - Company

- Pricing

- Software

DOWNLOADSINDUSTRIESSTANDARDS

Verwater verified a 24 m storage-tank roof using SDC for Ansys

Read Full Story - Consultancy

SERVICES

Analysis of the cylinder system of grab unloader

All Projects - Learning&Support

LEARN

AS 4100:2020 Fatigue in SDC Verifier – How Section 11 Is Implemented

Read Full Article - Company

- Pricing