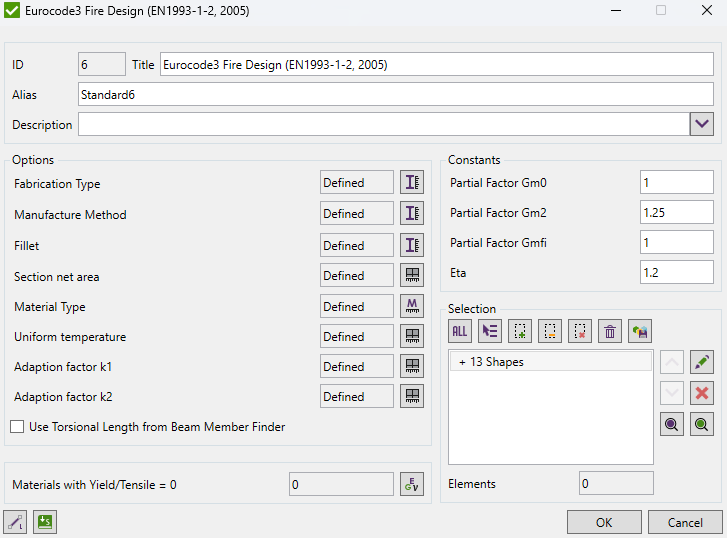

Eurocode3 Fire Design (EN1993-1-2, 2005)

Eurocode3 Fire Design (EN1993-1-2, 2005) describes the principles, requirements and rules for the structural design of steel buildings exposed to fire. Chapter 4 is implemented.

Note: Checks are performed for I-beams, Channels, Circular and Rectangular tubes.

To add the Standard execute from the ribbon:

Press  to Set Standard Custom Settings

to Set Standard Custom Settings

Options

Fabrication Type - Rolled or Welded;

Manufacture Method - Hot Finished or Cold Formed;

Fillet - size of the fillets of the cross-sections;

Section net area - for fasteners with holes net area has to be defined;

Material Type - the buckling curve (Table 6.2) depends on the material type. Material s460 has different classification then the other types;

Uniform temperature - the uniform steel temperature Qa at time t in a cross-section which is not thermally influenced by the support. Used in Table 3.1 to calculate reduction factors for stress-strain relationship of carbon steel at elevated temperatures;

Adaption factor k1 - an adaptation factor for non-uniform temperature across the cross-section (Chapter 4.2.3.3 (7));

Adaption factor k2 - an adaptation factor for non-uniform temperature along the beam (Chapter 4.2.3.3 (8));

Factors

Partial Factor Gm0 - resistance of cross-sections whatever the class is. Recommended value by National Annex = 1.00;

Partial Factor Gm2 - resistance of cross-sections in tension to fracture. Recommended value by National Annex = 1.25;

Partial Factor Gmfi - the partial factor for the relevant material property, for the fire situation. Recommended value by National Annex = 1.00;

Eta - is used in the shear area calculations (may be taken from the National Annex). The default value is 1.2;

Yield and Tensile

Standard uses material data (Yield/Tensile) in calculations. Wizard checks if the values are defined for all materials.