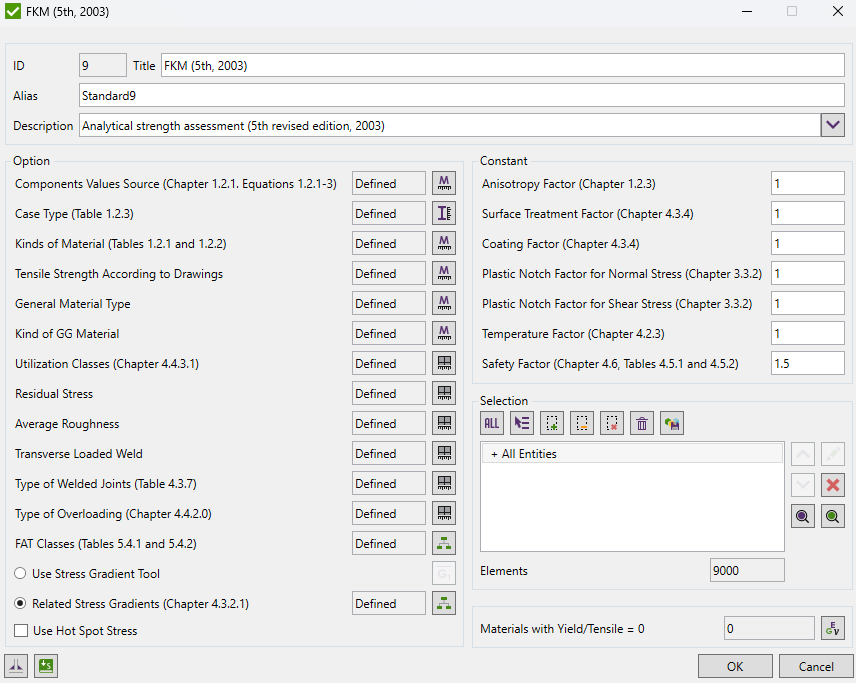

FKM (5th, 2003)

FKM (5th, 2003) – analytical strength assessment of components in mechanical engineering.

To add FKM (5th, 2003) standard execute from the ribbon:

Press  to Set Standard Custom Settings

to Set Standard Custom Settings

Components Values Source - material characteristic, Standards or Drawings (Chapter 1.2.1).

Case Type - used for defining effective diameter according to Table 1.2.3.

Kinds of Material - kinds of materials to define Deff and Adm constants, according to tables 1.2.1 and 1.2.2.

Tensile Strength According to Drawings - material tensile strength, RmZ.

General Material Type - the type of material, used for Fatigue Strength Factors. Table 4.2.1.

Kind of GG Material - determine constant Knl which accounts for the non-linear elastic stress-strain behavior of GG when loaded in tension-compression or bending. Table 4.3.6.

Utilization Classes - Variable amplitude fatigue strength factor (Chapter 5.7).

Residual Stress - High/Medium/Low.

Average Roughness - for polished surfaces. By default Rz = 1 (in micrometers).

Transverse Loaded Weld - for transversely loaded weld with thickness > 25 mm the thickness factor is calculated (Chapter 4.3.7).

Type of Welded Joints - used for calculation of Thickness Factor. Table 4.3.7.

Type of Overloading - distinguishes the way how the stress may increase in the case of a possible overload in service (Chapter 4.4.2.0).

FAT Classes - FAT classes for welded parts according to tables 5.4.1 and 5.4.2. For non welded parts 0.

Related Stress Gradient - can be calculated automatically by Stress Gradient tool or defined by classification (Chapter 4.3.2.1). By default the value 0.01 i used.

Use Hot Spot Stress - use Hot Spot Stress results for locations defined in Weld Finder Tool or Weld Stress results in the fatigue checks.

Constants

Anisotropy Factor - strength values of milled steel and forgings are lower transverse to the main direction of milling or forging than in the main direction of processing (Chapter 1.2.3).

Surface Treatment Factor - allows for the influence of a treated surface layer on the fatigue strength of the component (Chapter 4.3.4).

Coating Factor - allows for the influence of a surface coating on the fatigue strength of a component made of an aluminum alloy(Chapter 4.3.4) .

Plastic Notch Factor for Normal/Shear Stress - the section factors are limited by plastic notch factors that depend on the plastic limit load (Chapter 3.3.3).

Temperature Factor - considers that the material fatigue strength for completely reversed stress decreases with increasing temperature (Chapter 4.2.3).

Safety Factor - depends on the consequences of failure (severe/moderate) and regular inspections (Chapter 4.6, Tables 4.5.1 and 4.5.2).

Yield and Tensile

Standard uses material data (Yield/Tensile) in calculations. Wizard checks if the values are defined for all materials.