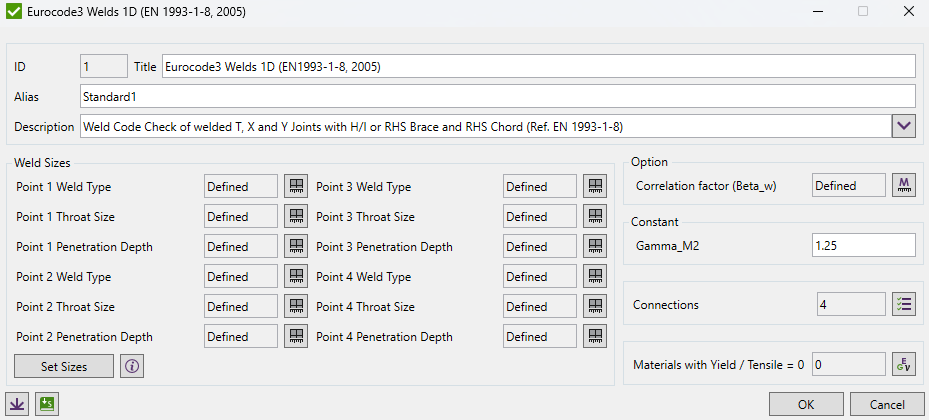

Eurocode 3 Welds 1D

Section 4 of the standard EN 1993-1-8:2005 Design of joints is implemented to check of welded T, X and Y joints with H/I or RHS brace and RHS chord (Ref. EN 1993-1-8).

To add the standard execute from the ribbon:

By default, all supported Connections (RHS chord and H/I or RHS braces) are included in the selection but it can be changed by pressing  .

If connections were not recognized press

.

If connections were not recognized press  to run Connection Finder tool.

to run Connection Finder tool.

Press  to Set Standard Custom Settings

to Set Standard Custom Settings

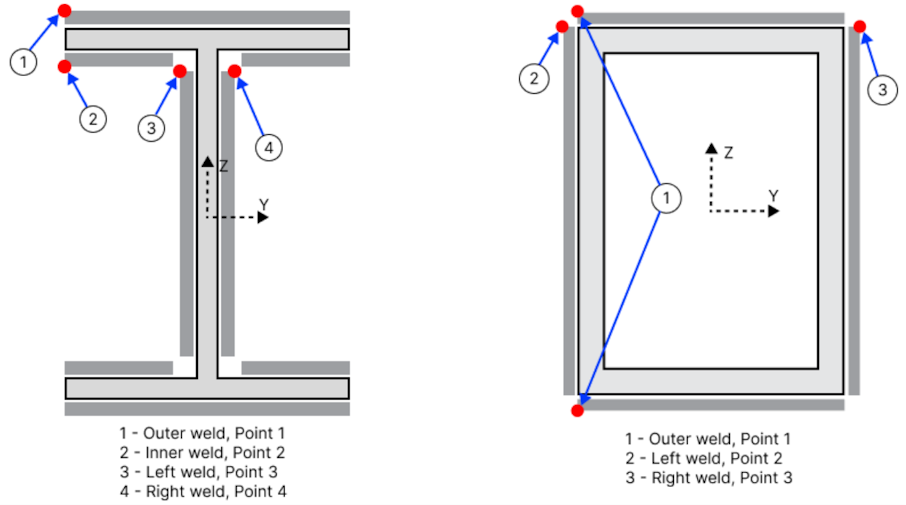

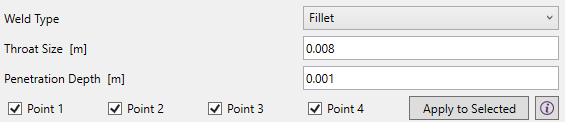

Weld Sizes

Weld sizes have to be set for 3 or 4 points shown above depending on shape.

Each point has fields to be set:

Point Weld Type - weld type used in point; can be Fillet, Partial Pen (Penetration), Partial Pen And Fillet, Flare Bevel or No Weld;

Point Throat Size - throat size of the weld at point, define in model length units for Fillet and Partial Pen And Fillet weld types;

Point Penetration Depth - penetration depth of the weld at point, define in model length units for Partial Pen, Flare Bevel and Partial Pen And Fillet weld types;

- to view details of weld sizes.

- to view details of weld sizes.

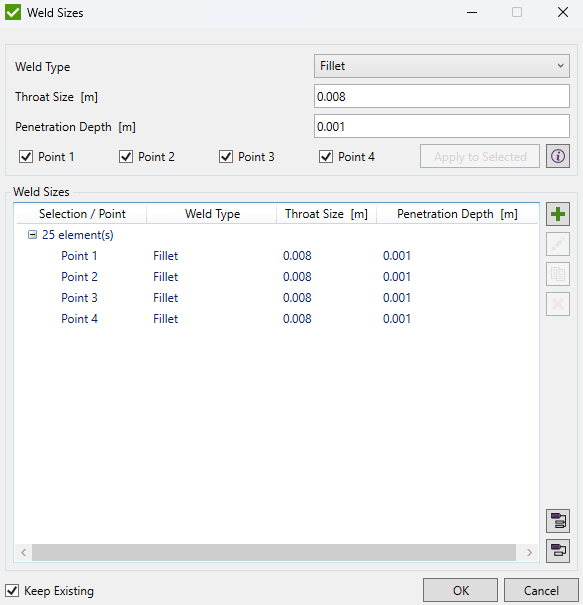

Press button to define multiple weld sizes:

- to add brace connection as selection:

- to add brace connection as selection:

Selection can be set by: Custom Selection, Components, Properties, Materials and Groups.

Define Weld Type, Throat Size, Penetration Depth, check points that sizes have to be applied and press to set sizes for selected connections.

- to view details of weld sizes.

- to view details of weld sizes.

Keep Existing - keep already set sizes, otherwise they will be overwritten with new ones.

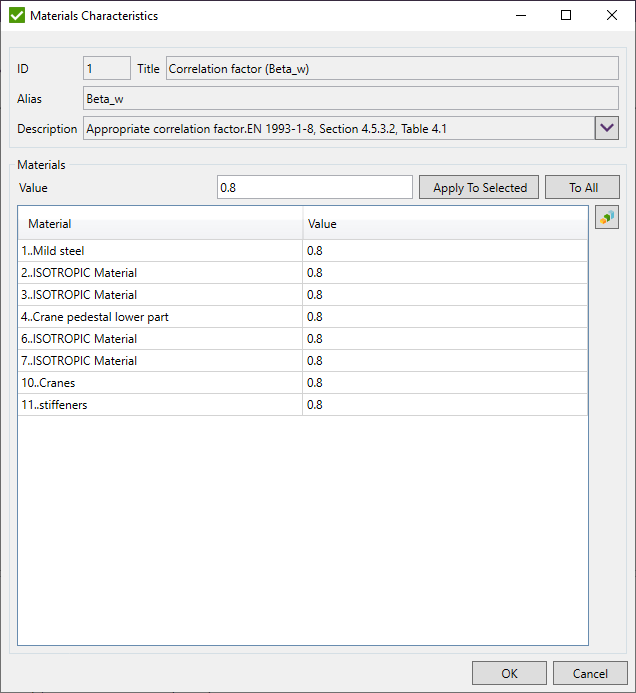

Press  to set a Correlation factor (Beta_w):

to set a Correlation factor (Beta_w):

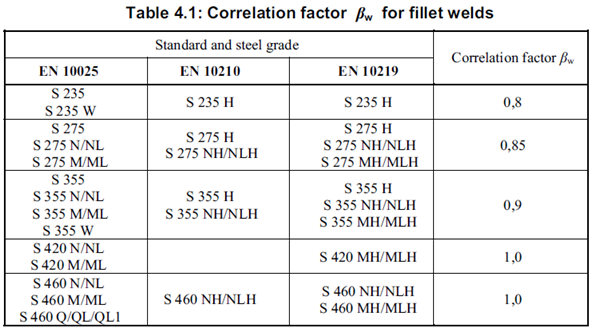

factor is obtained from the Table 4.1, section 4.5.3.2 and depends on the material type:

- material resistance factor for plated structures is a constant value (=1.25) and used in calculations to check a base material strength.

Press  to select connections from the list.

to select connections from the list.

Standard uses material data (Yield/Tensile) in calculations. Wizard checks if the values are defined for all materials.