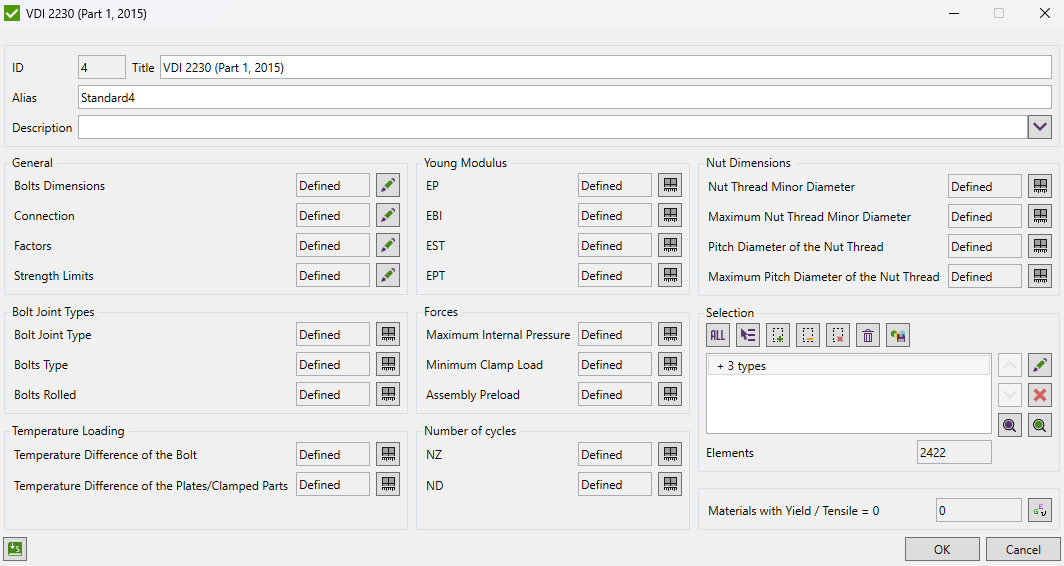

VDI 2230 (Part 1, 2015)

VDI 2330 (Part 1, 2015) - a VEREIN DEUTSCHER INGENIEURE staandard released in November, 2015.

This Standard works for calculating single-bolt joints with a systematic method, organized into calculation steps, for calculating bolted joints, thereby making possible a functionally and operationally reliable design which makes extensive use of the bolt's load-bearing capacity.

To add the standard execute from the ribbon:

Press  to Set Standard Custom Settings

to Set Standard Custom Settings

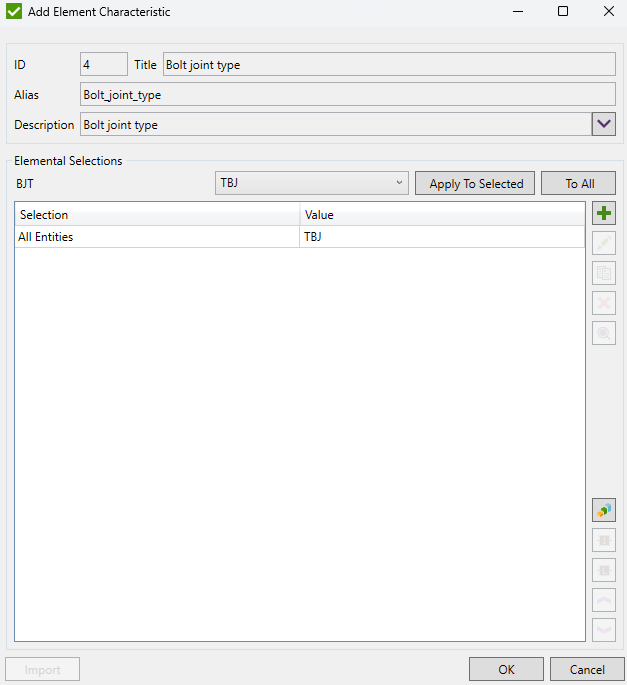

| Bolt Joint Type - can be TBJ (through-bolt joint) or TTJ (through-bolt joint); |

| Bolt Type - can be Hexagon head bolts or Socket head cap screws; |

| Bolt Rolled - set if bolt is rolled before or after heat treatment. |

| Temperature difference of the bolt; |

| Temperature difference of the plates/clamped parts. |

| EP - Young's modulus of the clamped parts; |

| EBI - Young's modulus of the component with internal thread; |

| EST - Young's modulus of the bolt material at a temperature different from room temperature; |

| EPT - Young's modulus of the clamped parts at a temperature different from room temperature. |

| Maximum internal pressure - maximum internal pressure in the joint connection; |

| Minimum clamp load - minimum clamp load (symmetrically clamped joint); |

| Assembly preload - assembly preload (Table A1). |

| NZ - number of alternating cycles during loading within the fatigue strength range; |

| ND - number of alternating cycles during continuous loading. |

| Nut thread minor diameter; |

| Maximum nut thread minor diameter - maximum nut thread minor diameter (depends on tolerances) (can be ignored in this case will be used Nut thread minor diameter); |

| Pitch diameter of the nut thread; |

| Maximum pitch diameter of the nut thread - maximum pitch diameter of the nut thread (depends on tolerances). |

Press  to define characteristic of standard:

to define characteristic of standard:

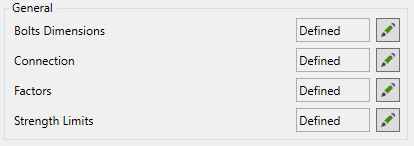

Press  to define Connection, Factors and Strength Limits, Bolts Dimensions.

to define Connection, Factors and Strength Limits, Bolts Dimensions.

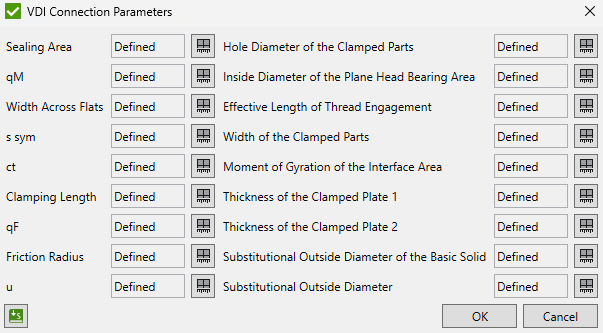

Connection:

| Sealing area (match AD in the standard document) - at most interface area less the through-hole for the bolt; |

| qM - number and position of the moment-transmitting interfaces; |

| Width across flats (match s in the standard document); |

| s sym - distance of the bolt axis from the axis of the imaginary laterally symmetrical deformation body; |

| ct - measurement of the interface area perpendicular to the width b; |

| Clamping length (match lk in the standard document); |

| qF - number and position of the force-transmitting interfaces; |

| Friction radius - friction radius is derived from the dimensions of the clamped components; |

| u - edge distance of the opening point U from the axis of the imaginary laterally symmetrical deformation body; |

| Hole diameter of the clamped parts (match dh in the standard document); |

| Inside diameter of the plane head bearing area (match dKi in the standard document) - used for requred tigtening torque calculation; |

| Effective length of thread engagement or nut height (match meff in the standard document) - used for m_eff checking if equl to 0 check will be ignored; |

| Width of the clamped parts (match b in the standard document Figure 13); |

| Moment of gyration of the interface area (match IBT in the standard document); |

| Thickness of the clamped plate 1; |

| Thickness of the clamped plate 2; |

| Substitutional outside diameter of the basic solid (match DA' in the standard document); |

| Substitutional outside diameter (match DA in the standard document) - substitutional outside diameter of the basic solid at the interface; if the interface area differs from the circular form, an average diameter is to be used. |

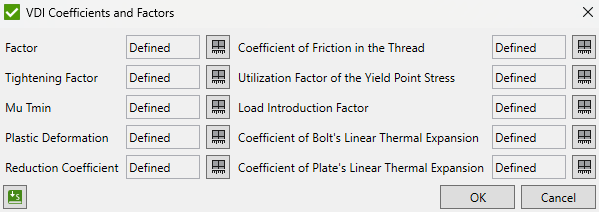

Factors:

| Factor - factor for G value calculation. Can be from 1.5 to 2; |

| Tightening factor; |

| Mu Tmin - approximate values for the range of coefficients of static friction in the interface (Table A6); |

| Plastic deformation - plastic deformation as a result of embedding, amount of embedding (Table 5); |

| Reduction coefficient - reduction coefficient (Chapter R8). For the reduced or comparative stress with a torsional stress reduced to k in service (recommendation: 0.5); |

| Coefficient of friction in the thread (Table A5); |

| Utilization factor of the yield point stress - utilization factor of the yield point stress (limit of full plasticization of the cross section at risk) during tightening; |

| Load introduction factor - load introduction factor for describing the effect of the introduction point of FA on the displacement of the bolt head, generally and for concentric lamping (Table 2); |

| Coefficient of linear thermal expansion of the Bolt; |

| Coefficient of linear thermal expansion of the Plate. |

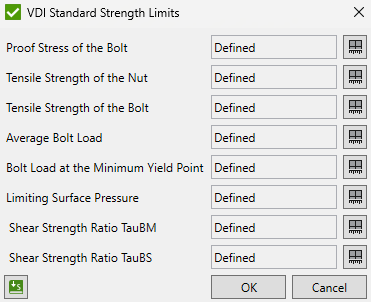

Strength Limits:

| Proof stress of the bolt - 0.2 % proof stress of the bolt according to DIN EN ISO 898-1; |

| Tensile strength of the nut (Table A9); |

| Tensile strength of the bolt (Table A9); |

| Average bolt load - required only for bolts rolled after heat treatment; |

| Bolt load at the minimum yield point - required only for bolts rolled after heat treatment; |

| Limiting surface pressure - maximum permissible pressure under bolt head, nut or washer (Table A9); |

| Shear strength ratio TauBM - shear strength ratio (Table 6); |

| Shear strength ratio Tau_BS - shear strength ratio (Table 7); |

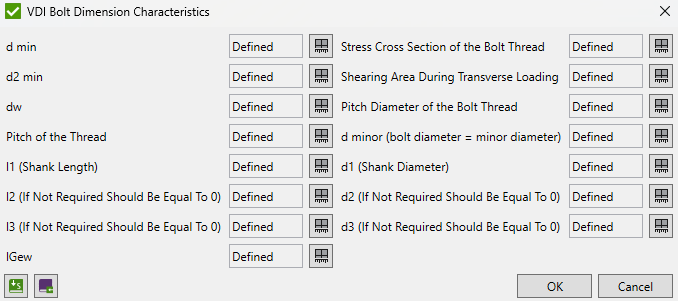

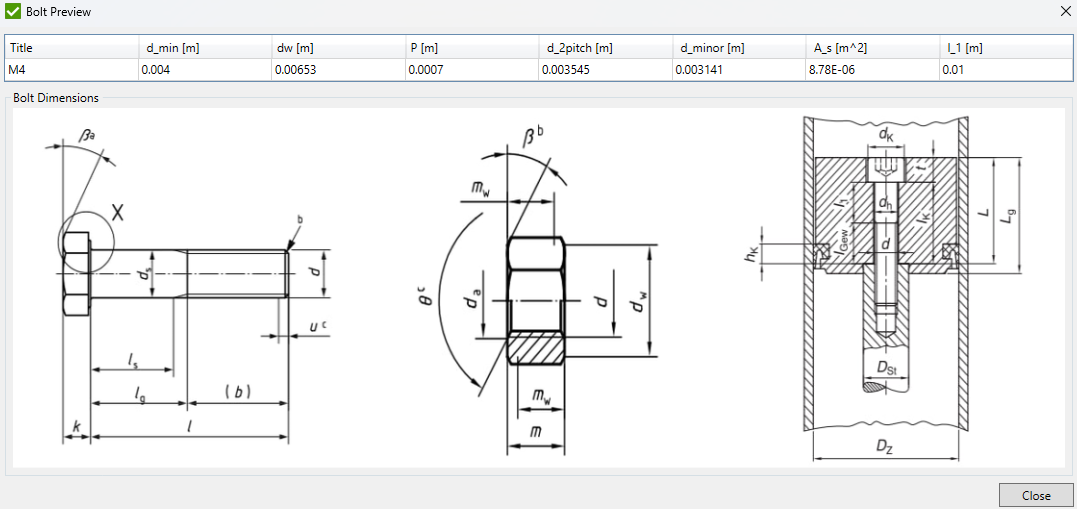

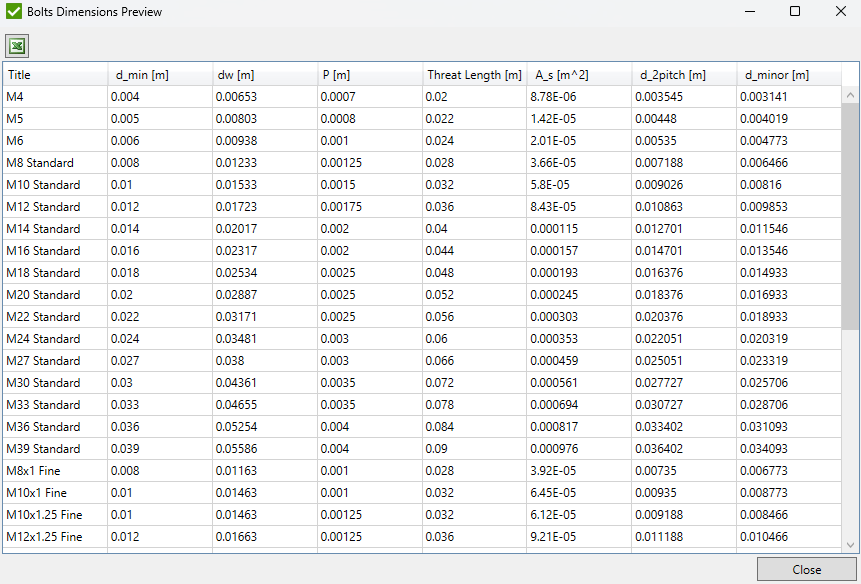

Bolts Dimensions:

| d min (match d in the standard document) - minimum bolt diameter = outside diameter of thread (nominal diameter); |

| d2 min - minimum pitch diameter of the bolt thread (can be ignored in this case will be used Pitch diameter of the bolt thread); |

| dw (match dw in the standard document) - outside diameter of the plane head bearing surface of the bolt; |

| Pitch of the Thread (match P in the standard document) - pitch of the thread (Table A11); |

| l1 (match l1 in the standard document) - length of an individual cylindrical element of the bolt (shank length); |

| lGew (match lGew in the standard document) - length of the free loaded thread; |

| Stress Cross Section of the Bolt Thread (match As in the standard document) - stress cross section of the bolt thread according to DIN 13-28 (Table A11); |

| Shearing Area During Transverse Loading - shearing area during transverse loading; |

| Pitch diameter of the Bolt Thread (match d2 in the standard document) - pitch diameter of the bolt thread (Table A11); |

| d minor (match d3 in the standard document) - minor diameter of the bolt thread (Table A12); |

| d1 (match dT in the standard document) - shank diameter. |

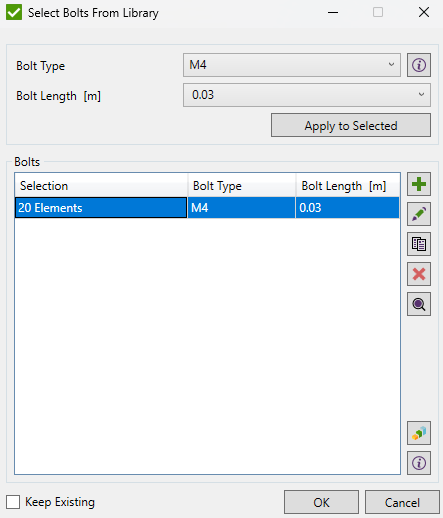

Bolts Library

It is possible to load d min, dw, Pitch of the Thread, Pitch diameter of the Bolt Thread, d minor, Stress Cross Section of the Bolt Thread, l1 Bolt Dimensions from library.

Press  to open library:

to open library:

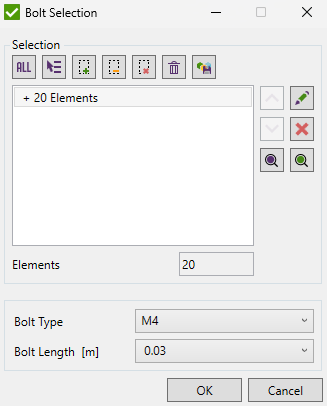

Press  to add bolt:

to add bolt:

It is possible to set selection from Components, Materials, Properties or press Group to select elements manually:

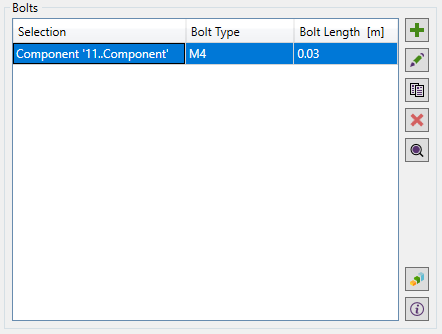

There are options to Edit, Highlight and Plot added bolts:

For more detailed preview of selected bolt press  :

:

Selected bolt's type can be changed. Select bolt type and length that correspond to requirement and press  to finish modification:

to finish modification:

It is possible to preview dimensions of all bolts. Press  to open preview window:

to open preview window:

To keep previously defined bolt dimensions characteristics option Keep Existing must be checked. Otherwise, previouse created bolt dimensions will be cleared.

All bolts from the list will be added automatically to respective characteristics.