Conduct fatigue checks directly in ANSYS using SDC Verifier

Template-based design automates future routine work, and automated documentation facilitates report generation

A lot of steel structures such as cranes, heavy machinery and other equipment subjected to repetitive loading is highly likely to develop cracks or failures because of the fatigue damage. The cost of every hour of equipment downtime is usually very expensive, making it mandatory to perform residual life calculations or fatigue checks.

The complexity of this problem, which prescribes to take into account a lot of calculation details for the realistic fatigue life prediction, makes it a time-consuming task without proper fatigue analysis software.

The fatigue verification procedure usually consists of the following important steps:

1. Gathering information about the working conditions, loading history, and material data, and then preparing the Basis of Calculation including loads, boundary conditions, load combinations with partial load factors, and safety factors.

2. Recognition of the welds and setting the weld classification, material properties, and defining the working conditions.

3. Verification of fatigue damage according to the standards and rules to guarantee the safety and reliability of the structure.

4. Modifications to the design to achieve the desired results, optimize the design, or save costs.

5. Documentation of the results, based on the fatigue analysis, for submission to a certification organization/the customer.

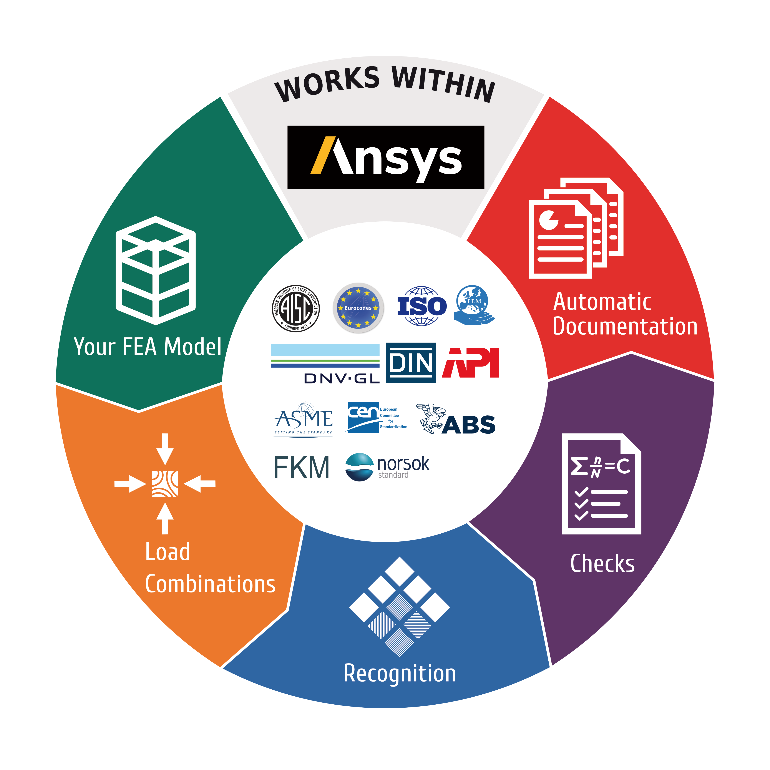

With the help of SDC Verifier, this procedure is completely automated and can be performed directly in the Ansys Mechanical model! Hereby it not only allows fatigue analysis in ANSYS according to industry standards, but helps to simplify this task significantly and save a huge amount of time with complete automation!

Basis of calculation

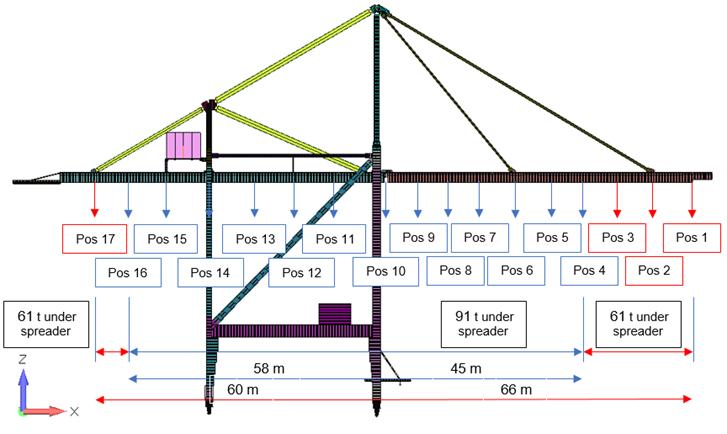

It makes no difference whether it is a new design check, a residual life analysis, or a crack investigation – it is very important to collect and properly transfer to the finite element analysis (FEA) model all necessary information about the working conditions and loading history of the structure (or the estimated loads for a new design). A realistic Basis of Calculation results in more precise calculation results.

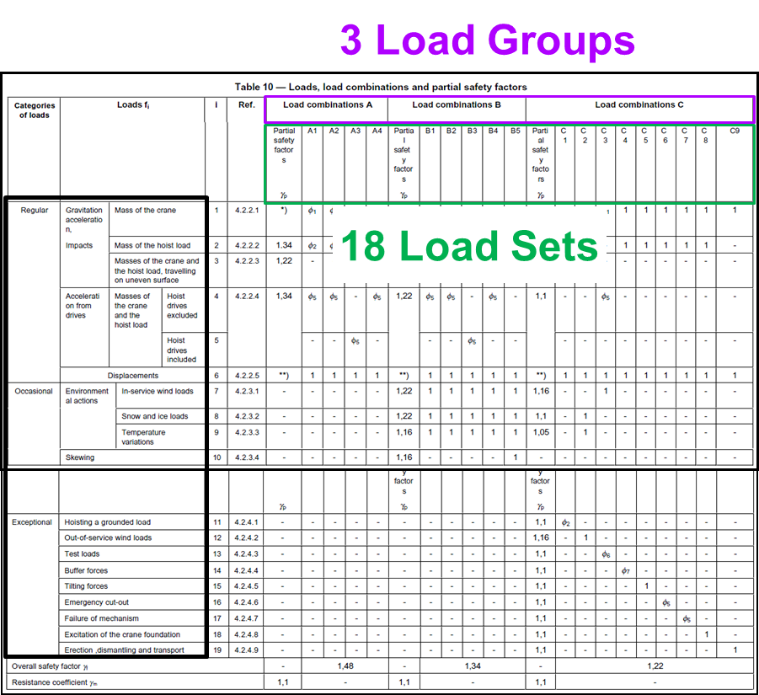

The combination of loads and impacts is usually set by the standards and requires several groups of linear combinations of single load results. For example, according to FEM 1.001 fatigue testing, an engineer should combine: gravity, effective loading, acceleration and dynamic impact in all possible scenarios, taking into account partial load factors, dynamic and gain coefficients for the Strength group of load combinations with a safety factor of 1.5. All the same conditions plus the effect of wind must be combined for the Wind group of load combinations with a safety factor of 1.33. The next group will be an exceptional load scenario where the same effects have different partial load factors and a safety factor of 1.1.

At this point, the SDC Verifier offers the engineer a user-friendly interface for combining the loads into a matrix of load sets and groups, taking into account all the safety factors and partial load factors. Not only does this simplify the processing of a large amount of load history data, but it also shortens the Ansys Mechanical solution time (and therefore ANSYS Fatigue analysis) because each load effect will be solved once with ANSYS only and then linearly combined using SDC Verifier.

Setting the classification

In the second stage, there are three important characteristics that should be set to obtain realistic results of fatigue analysis:

- weld type or fat class (notch grade) – which determines the quality of the weld;

- material – which determines the grade of steel that the structure is made of; and

- element group – which determines the intensity of load and usage of the verified structure.

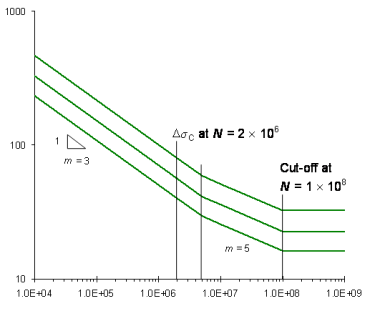

Weld type is crucial because fatigue problems are most likely to occur on welds. Therefore, in the S-N curve fatigue analysis method it is necessary to establish a classification based on a weld type to assign a curve. The general curve of the stress level against endurance is shown below.

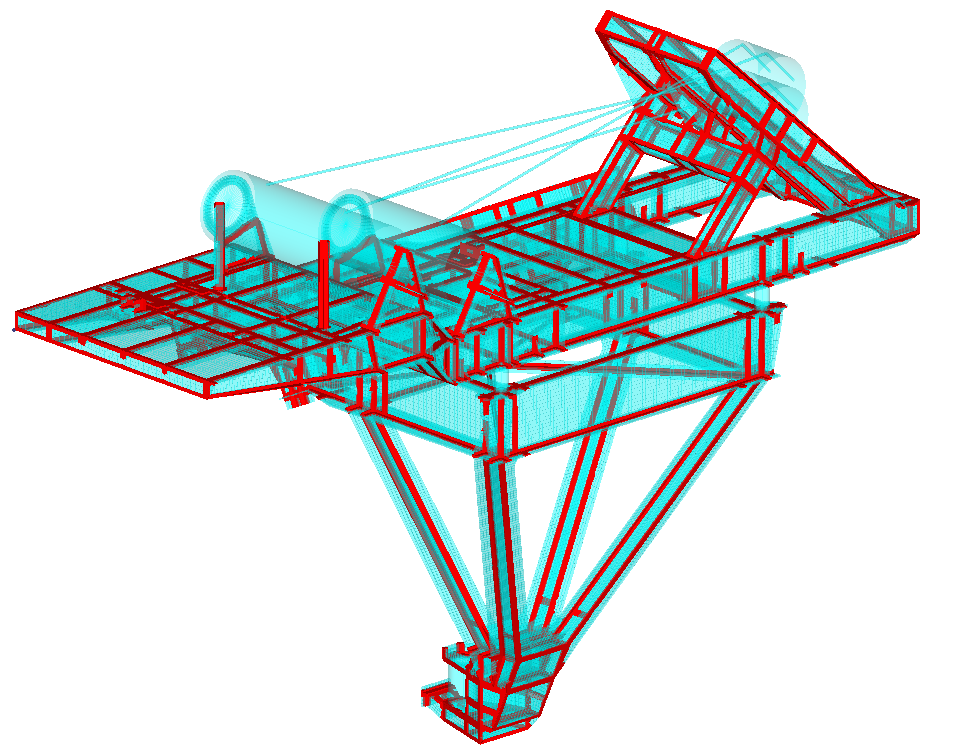

The first challenge is determining which elements of your FEA model are welds. The SDC Verifier Weld finder tool (part of SDC Verifier FEA Recognition Tools) solves this problem by introducing automatic one-click weld recognition. It automatically finds all welds in the FEA model based on thickness change, material/property change, joint angle and user-defined rules or exceptions.

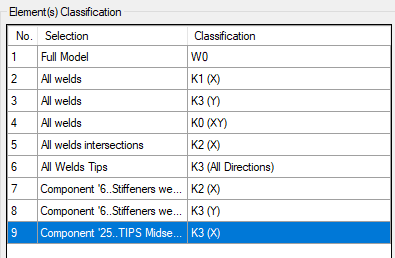

After the recognition is complete, the classification must be determined for all welds in the model. SDC Verifier’s selector helps you create components for all welds, weld intersections, weld tips, etc. Moreover, since the Weld finder reorients the stresses and forces in the welding directions, different classifications can be made along the weld, perpendicular to the weld, and for shear.

Material type is often sourced from ANSYS Mechanical or can be easily set in SDC Verifier (there is an automatic reminder if some of the material properties are not set).

Standards-based verification

The next step is the fatigue verification itself. SDC Verifier performs the fatigue check according to different standards in the Offshore, Heavy lifting, Heavy machinery, Maritime, Shipbuilding and Civil industries. The following engineering standards are currently available:

- Eurocode 3 (EN1993-1-9, 2005)

- EN 13001 (2018)

- FEM 1.001 (3rd, 1998)

- DNV-RP-C203 (2016)

- DIN 15018 (1984)

- FKM Guidelines

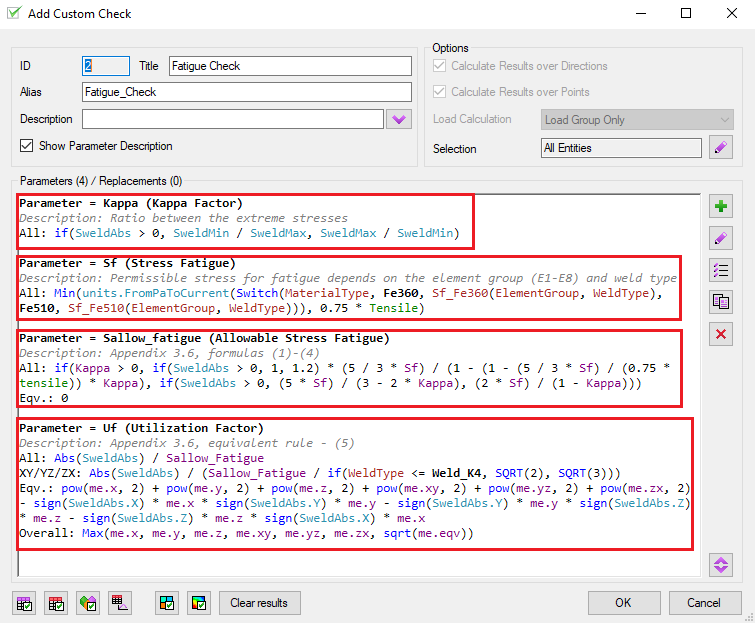

SDC Verifier uses the Allowable Stress Design method. All formulas are open, so the user can see all the formulas behind the calculation kernel, including descriptions and explanations of where they have been taken from.

Before running the calculation, the user only needs to select the part of the model to be tested and the loads to be used in the calculation. All calculations are performed in the background, however it is possible to access a log file of the calculation details if full control of the ANSYS fatigue analysis is required.

Modifications to the design

In the initial phase, modifications to the design seem to be a minor part of the project execution time. But if the fatigue analysis results are not as expected and improvements are required, then the complete review process usually takes much longer than expected.

SDC Verifier is template-based, which means that if the check has been done once, then in the future, routine work will be automated on the basis of calculation, recognition, and the calculations themselves. All the user has to do is change the design and solve the model. Subsequently, the data is updated and a report is generated with two mouse clicks, to complete the entire procedure.

This is a huge time saver and reduces deadline pressure because, as we all know, most design modifications and improvements are done at the last minute!

Documentation automation

Last, but not least, is the automatic reporting. Few people like writing reports. However, there is still a great deal of documentation that must be provided to a manager, customer or certification organization.

The SDC Verifier Report designer helps you to create a template-based document that contains the following info: model description, loads and boundary conditions, ANSYS results output, and code validation results. All data can be presented with an extensive range of plots and tables.

Full control over the structure of the tables makes it possible to present the maximum or detailed output result for the complete model or individual components over the loads and combinations, or to prepare an overview table of the various load parameters. With adjustable view settings and selectors, the user can create any output or check result at a different angle/view for the full model, some part or cut.

With SDC Verifier that allows the code to be verified directly in ANSYS, there is no longer a need for routine manual calculations, spreadsheets, or complicated testing and verification procedures to check the fatigue damage or to predict the residual life of a structure. In addition, you can generate a full calculation and verification report to submit to the certifying organization or customer.